At its core, the primary advantage of a PTFE reducing flange's non-stick property is its ability to ensure uninterrupted and clean fluid transfer. This surface characteristic dramatically reduces friction and prevents process media from adhering to the flange, which directly maintains smooth flow and minimizes the risk of costly blockages within a piping system.

While the immediate benefit is preventing material from sticking, the true advantage lies in how this single characteristic drives down operational costs, improves system reliability, and ensures process integrity over the long term.

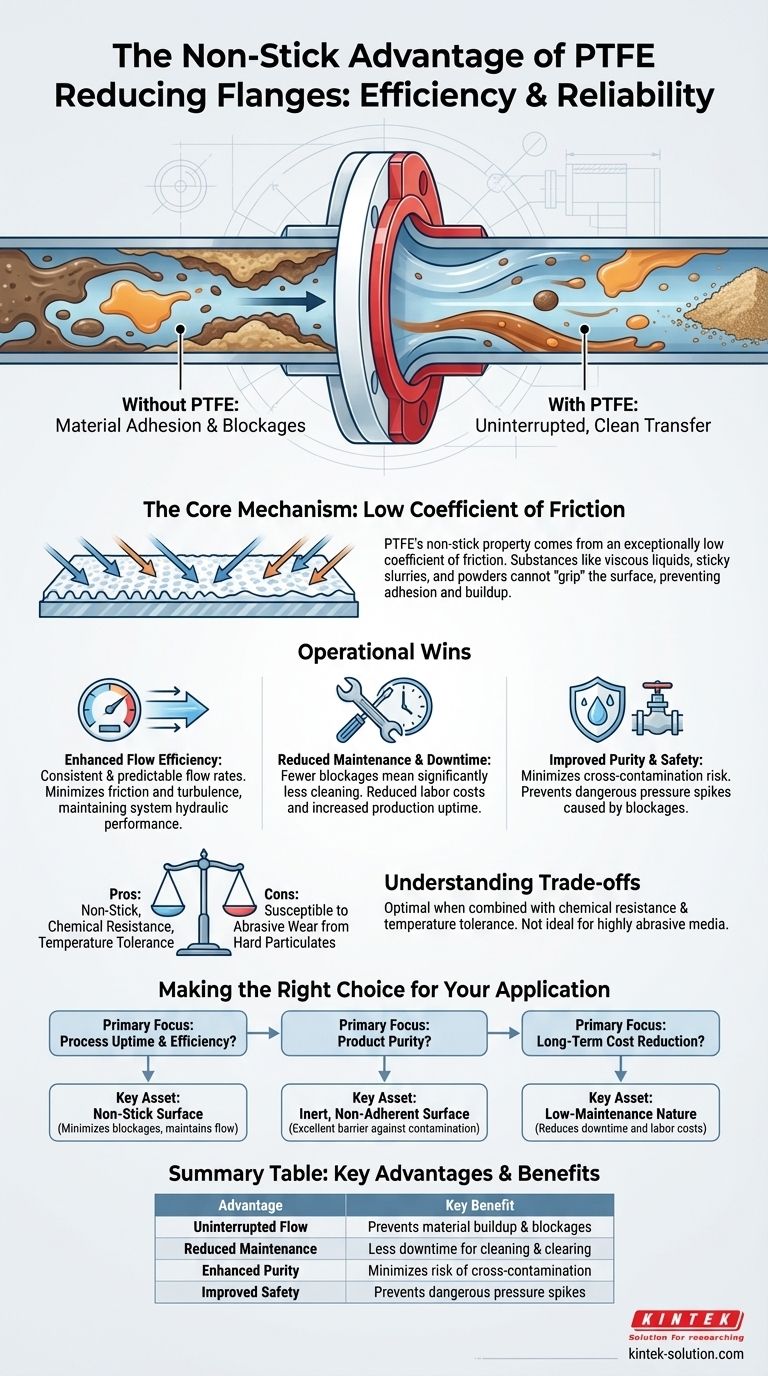

The Core Mechanism: How PTFE's Surface Works

The term "non-stick" is a functional description of a fundamental material property. Understanding this mechanism is key to appreciating its impact on your operations.

What "Non-Stick" Really Means

The non-stick quality of Polytetrafluoroethylene (PTFE) comes from its exceptionally low coefficient of friction. It is one of the lowest of any solid material.

This means that other substances, whether they are viscous liquids, sticky slurries, or powders, have very little ability to "grip" or bond to the flange's surface.

Preventing Material Adhesion and Buildup

In industrial processes, material buildup is a constant threat. It can restrict flow, create pressure drops, and contaminate subsequent batches.

The non-stick surface of PTFE directly counteracts this by preventing materials from accumulating. This is especially critical when handling adhesives, food products, or chemicals that tend to solidify or cling to surfaces.

Translating Non-Stick Properties into Operational Wins

The low-friction surface is not just a feature; it is a direct driver of efficiency, safety, and cost-effectiveness in any system where it is deployed.

Enhanced Flow Efficiency

A smooth, non-adherent surface ensures that the flow rate and pressure within the piping system remain consistent and predictable.

By minimizing the friction and turbulence caused by surface roughness or buildup, PTFE reducing flanges help maintain the designed hydraulic performance of the entire system, boosting overall productivity.

Reduced Maintenance and Downtime

Fewer blockages and less material buildup mean significantly less need for maintenance.

Systems do not need to be shut down as frequently for cleaning or clearing obstructions. This translates directly into reduced labor costs, increased production uptime, and a longer service life for the component itself.

Improved Purity and Safety

Because materials do not adhere to the surface, the risk of cross-contamination between different batches or processes is greatly reduced.

Furthermore, preventing blockages is a critical safety function. A sudden blockage can cause dangerous pressure spikes in a system, leading to potential leaks or catastrophic failure.

Understanding the Trade-offs

While highly effective, the non-stick property of PTFE must be considered within the context of the overall application. No material is a universal solution.

It Works as Part of a System

The non-stick surface is one of PTFE's key features, alongside its excellent chemical resistance and wide temperature tolerance.

The true value is realized when all these properties work together. A non-stick surface is of little use if the material cannot withstand the process chemicals or temperature.

Not Ideal for Highly Abrasive Media

PTFE is a relatively soft material. While it has low friction, it can be susceptible to wear from highly abrasive slurries or media containing hard particulates.

In such cases, the abrasive action can eventually wear away the smooth surface, diminishing its non-stick effectiveness over time.

Making the Right Choice for Your Application

Selecting a PTFE reducing flange should be based on a clear understanding of your primary operational goal.

- If your primary focus is process uptime and efficiency: The non-stick surface is your greatest asset, as it directly minimizes blockages and maintains consistent flow rates.

- If your primary focus is product purity: The inert, non-adherent surface provides an exceptional barrier against contamination between batches.

- If your primary focus is long-term cost reduction: The low-maintenance nature of PTFE, driven by its non-stick properties, significantly reduces costs associated with downtime and labor.

Ultimately, leveraging the non-stick advantage of PTFE allows you to design a more resilient, efficient, and reliable piping system.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Uninterrupted Flow | Prevents material buildup & blockages |

| Reduced Maintenance | Less downtime for cleaning & clearing |

| Enhanced Purity | Minimizes risk of cross-contamination |

| Improved Safety | Prevents dangerous pressure spikes |

Ready to eliminate blockages and reduce maintenance costs in your piping system?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom reducing flanges, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a component that leverages non-stick properties for maximum operational efficiency and reliability.

Let us help you design a more resilient system. Contact KINTEK today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the importance of torque checks in PTFE butterfly valves? Prevent Leaks & Extend Valve Life

- What role does PTFE play in the printing and packaging industry? Enhancing Efficiency and Quality

- What are the cost implications of choosing PTFE over NBR for butterfly valve seats? A Guide to True Cost of Ownership

- What are the key design features of PTFE bushings? Achieve Maintenance-Free, High-Performance Bearing Solutions

- What is a PTFE ball valve and how does it function? The Ultimate Guide to Corrosion-Resistant Flow Control

- Why are PTFE seats preferred in electric actuated butterfly valves? Enhance Valve Performance and Actuator Lifespan

- What are the key characteristics of Teflon seals? Unmatched Chemical & Temperature Resistance

- What are the common applications of virgin Teflon balls? Ideal for Chemical Resistance & Purity