Beyond its well-known friction and chemical resistance, Polytetrafluoroethylene (PTFE) offers a distinct set of advantages over rubber composites, primarily centered on its exceptional environmental stability, predictable performance under pressure, and superior electrical properties. Unlike rubber, PTFE does not degrade from age or UV exposure, is not susceptible to moisture absorption or explosive decompression, and functions as a premier electrical insulator.

The core advantage of PTFE lies not in a single attribute, but in its unique combination of extreme durability and operational stability. This makes it a "fit-and-forget" material for critical applications where rubber-based components would degrade, fail, or require frequent replacement.

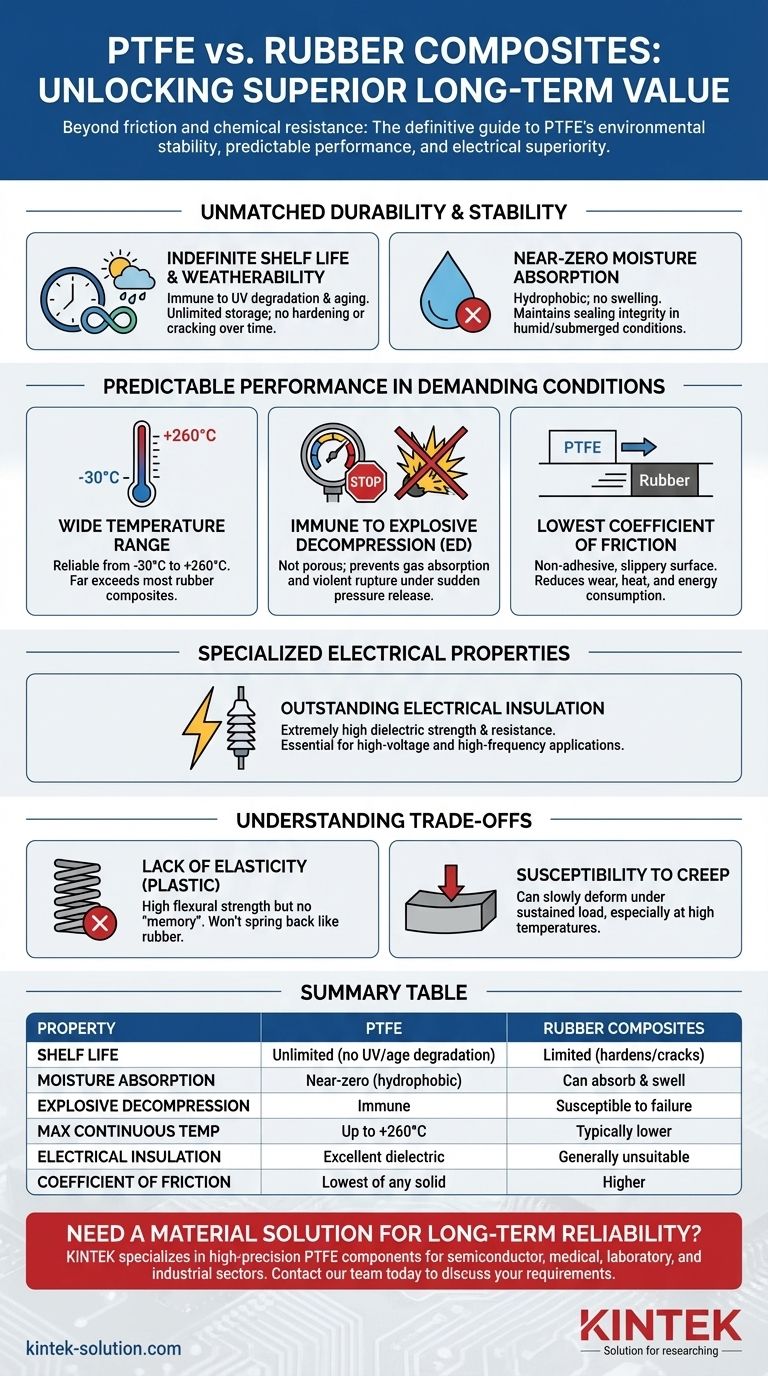

Unmatched Durability and Environmental Stability

The fundamental difference in longevity between PTFE and rubber stems from their chemical structures. PTFE's strong carbon-fluorine bonds make it exceptionally resilient to environmental stressors that break down rubber over time.

Indefinite Shelf Life

PTFE is virtually immune to degradation from UV light and the effects of aging. This means a PTFE component has an essentially unlimited shelf life, allowing it to be stored for years without any loss of mechanical integrity or performance. Rubber composites, in contrast, will harden, crack, and lose their properties over time.

Superior Weatherability

This resistance to UV light and aging also translates to outstanding weatherability. PTFE can be used in outdoor applications with prolonged exposure to the elements without deteriorating, a key failure point for many types of rubber.

Resistance to Moisture Absorption

Rubber composites can absorb moisture, causing them to swell. This change in dimension can compromise sealing integrity and alter mechanical properties. PTFE is hydrophobic and has near-zero water absorption, ensuring its size and performance remain constant even in humid or submerged conditions.

Predictable Performance in Demanding Conditions

PTFE maintains its integrity and provides consistent performance in operational environments that can cause catastrophic failure in rubber seals and components.

Wide Operating Temperature Range

PTFE performs reliably across a vast temperature spectrum, typically from -30°C up to +200°C, and can withstand continuous working temperatures as high as +260°C. This range far exceeds that of most standard rubber composites.

Immunity to Explosive Decompression

In high-pressure gas applications, rubber can absorb the gas into its molecular structure. If the system pressure is released suddenly, this trapped gas expands violently, rupturing and destroying the rubber seal from the inside out. PTFE is not porous in this way and is therefore immune to explosive decompression (ED) failure.

The Lowest Coefficient of Friction

While a well-known property, its implication is critical. PTFE has the lowest coefficient of friction of any solid material. This non-adhesive, "slippery" surface is a significant benefit over rubber in dynamic applications, reducing wear, heat generation, and the energy required to move components.

Specialized Electrical Properties

For applications in electronics and electrical systems, the difference between PTFE and rubber is night and day.

Outstanding Electrical Insulation

PTFE possesses extremely high dielectric strength and electrical resistance. This makes it one of the best insulating materials available, essential for high-frequency connectors, cable insulation, and components in high-voltage equipment where rubber would be entirely unsuitable.

Understanding the Trade-offs

While its benefits are significant, PTFE is not a universal replacement for rubber. The choice depends entirely on the application's specific requirements.

Lack of Elasticity

The most critical difference is that PTFE is a plastic, not an elastomer. It has high flexural strength but lacks the "memory" and compressibility of rubber. It will not spring back to its original shape after being compressed in the same way a rubber O-ring would.

Susceptibility to Creep

Under a constant, sustained load (especially at elevated temperatures), PTFE can be susceptible to "creep" or cold flow, meaning it can slowly deform over time. In static sealing applications that rely on a constant sealing force, this must be accounted for in the design.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary engineering goal.

- If your primary focus is long-term stability and storage: PTFE's unlimited shelf life and resistance to UV, aging, and moisture make it the definitive choice.

- If your primary focus is dynamic sealing in high-pressure or high-temperature environments: PTFE's low friction, wide temperature range, and immunity to explosive decompression are critical advantages.

- If your primary focus is electrical insulation: PTFE's dielectric properties are vastly superior to rubber composites and make it the default material for demanding electrical applications.

- If your primary focus is compliant, static sealing at a lower cost: A traditional rubber composite is often more suitable due to its superior elasticity and ability to conform to surface imperfections.

By understanding these core differences, you can select the material that provides not just a solution, but long-term reliability for your specific engineering challenge.

Summary Table:

| Property | PTFE | Rubber Composites |

|---|---|---|

| Shelf Life | Unlimited (no UV/age degradation) | Limited (hardens/cracks over time) |

| Moisture Absorption | Near-zero (hydrophobic) | Can absorb moisture and swell |

| Explosive Decompression | Immune | Susceptible to failure |

| Max Continuous Temp | Up to +260°C | Typically lower |

| Electrical Insulation | Excellent dielectric strength | Generally unsuitable for high-voltage |

| Coefficient of Friction | Lowest of any solid | Higher |

Need a material solution that offers long-term reliability and superior performance?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your components deliver unmatched durability, stability, and electrical insulation.

Contact our team today to discuss how our PTFE solutions can meet your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries commonly use RPTFE and for what purposes? Enhance Durability in High-Load Applications

- What makes PTFE/Teflon suitable for medical applications? Discover Its Unique Biocompatibility & Performance

- What makes PTFE useful for non-stick applications? The Science Behind Its Slick Surface

- What makes PTFE's low friction properties advantageous for aerospace applications? Achieve Unmatched Reliability and Efficiency

- What is ePTFE and how is it produced? Unlock the Power of Microporous PTFE

- What are some alternative names for PTFE? Unlocking the Versatility of Teflon and TFE

- How does PTFE contribute to durability and longevity in industrial applications? Enhance Equipment Lifespan with PTFE

- What are the benefits of using Teflon in fiberglass? Achieve Unmatched Durability and Chemical Resistance