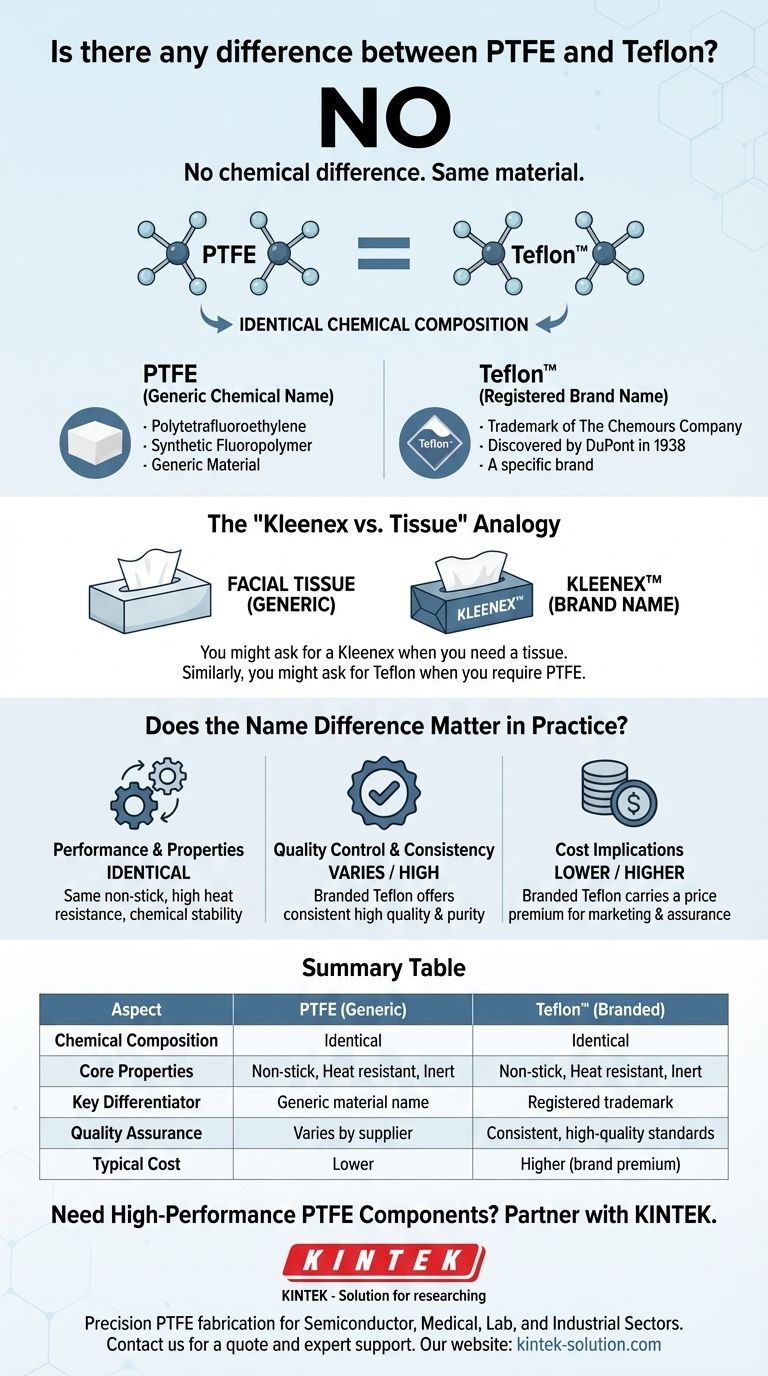

No, there is no chemical difference between PTFE and Teflon. They are precisely the same material. PTFE, which stands for Polytetrafluoroethylene, is the generic chemical name for the synthetic polymer. Teflon™ is simply the registered trademark and brand name under which this material is marketed by its owner, The Chemours Company.

The distinction between PTFE and Teflon is one of branding, not chemistry. Teflon is a specific brand of PTFE, much like Kleenex is a specific brand of facial tissue. While the core material is identical, the brand name can sometimes imply specific quality standards, formulations, or cost.

The Core Relationship: Chemical vs. Brand

To make informed decisions, it's crucial to understand the fundamental relationship between the generic material and the well-known brand.

What is PTFE?

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer, a type of high-performance plastic.

It is renowned for its exceptional properties, including an extremely low coefficient of friction (making it one of the "slickest" substances known), high heat resistance, and excellent chemical inertness.

What is Teflon?

Teflon™ is the brand name for PTFE that was discovered by DuPont in 1938. The brand's commercial success was so immense that, for many people, the name became synonymous with the material itself.

This phenomenon, known as a proprietary eponym, is common with highly successful products.

The "Kleenex vs. Tissue" Analogy

The easiest way to understand the relationship is to compare it to facial tissues. You might ask for a Kleenex (the brand name) when what you need is a facial tissue (the generic product name).

Similarly, one might ask for Teflon when they require the material PTFE. All Teflon is PTFE, but not all PTFE is sold under the Teflon brand.

Does the Name Difference Matter in Practice?

While the underlying chemical is the same, the choice between generic PTFE and branded Teflon can have practical implications related to quality and cost.

Performance and Properties

From a purely technical standpoint, the material properties are identical. A component made of pure, generic PTFE and one made of Teflon-branded PTFE will have the same non-stick characteristics, temperature resistance, and chemical stability.

Quality Control and Consistency

A significant potential difference lies in manufacturing and quality control. Major brands like Teflon often invest heavily in ensuring high purity, consistent molecular weight, and strict process controls.

For highly sensitive applications in aerospace, medical, or industrial fields, specifying the Teflon brand can provide an added layer of assurance regarding material consistency and reliability.

Cost Implications

Branded products almost always carry a price premium, and Teflon is no exception. The cost difference is attributed to marketing, brand recognition, and the rigorous quality assurance programs associated with the name.

Generic PTFE from a reputable supplier can offer the same performance for many applications at a lower cost.

Understanding the Trade-offs

Choosing between the two is not about which material is "better," but which is more appropriate for your specific needs and budget.

The Myth of a "Better" Material

Teflon is not a chemically superior version of PTFE. Any perceived superiority comes from the manufacturer's processes, not from a different chemical formula. A low-quality batch of branded material will underperform compared to a high-quality batch of generic material.

The "Teflon" Family of Products

It's important to note that Chemours markets an entire family of related fluoropolymers under the Teflon™ brand, not just PTFE. This includes other polymers like FEP and PFA, which have different properties.

This means that if a product is labeled "Teflon," it's crucial to verify if it is specifically PTFE or another polymer in that family.

When Generic PTFE is Sufficient

For many general-purpose applications where basic non-stick, insulating, or low-friction properties are needed, a high-quality generic PTFE is perfectly adequate. The key is to source it from a trustworthy supplier who can provide a certificate of conformity or a material data sheet.

Making the Right Choice for Your Application

Your final decision should be guided by the specific demands of your project.

- If your primary focus is a critical industrial or medical application: The proven consistency and quality assurance of the Teflon brand may be worth the additional investment.

- If your primary focus is purchasing consumer products like cookware: Judge the product on its overall quality, construction, and reviews rather than simply the presence of the Teflon name.

- If your primary focus is sourcing raw material for general fabrication: A reputable supplier of generic PTFE is often the most cost-effective choice, provided you verify their material specifications.

Understanding this distinction empowers you to look beyond the marketing and focus on the material properties that truly matter for your project's success.

Summary Table:

| Aspect | PTFE (Generic) | Teflon™ (Branded) |

|---|---|---|

| Chemical Composition | Identical | Identical |

| Core Properties | Non-stick, high heat resistance, chemical inertness | Non-stick, high heat resistance, chemical inertness |

| Key Differentiator | Generic material name | Registered trademark by Chemours |

| Quality Assurance | Varies by supplier | Consistent, high-quality standards |

| Typical Cost | Lower | Higher (brand premium) |

Need High-Performance PTFE Components? Partner with KINTEK

Understanding the distinction between PTFE and Teflon is the first step. The next is sourcing high-quality components from a trusted manufacturer. At KINTEK, we specialize in precision PTFE fabrication for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

Whether you require standard parts or custom-designed seals, liners, or labware, we deliver the material performance and reliability your project demands. We work with you from prototypes to high-volume production.

Let's discuss your specific requirements: Contact KINTEK today for a quote and expert support.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the dispersion method of producing PTFE and what are its products? Ideal for Thin Coatings and Films

- What benefits does Teflon coating offer in chemical manufacturing? Boost Equipment Lifespan & Purity

- What is the thermal stability range of PTFE? From -200°C to 260°C, but understand the critical limits.

- How does PTFE's chemical resistance compare to other plastics? Discover the Ultimate Inert Material

- What additional benefits does PTFE offer compared to rubber composites? Uncover Superior Stability & Performance

- How does PTFE perform against various chemicals? Unmatched Chemical Resistance for Demanding Applications

- What is the reactivity of PTFE and why is it inert? Discover the Science Behind Its Unmatched Chemical Resistance

- What is the difference between PTFE and Teflon? Uncover the Truth to Make Smarter Sourcing Decisions