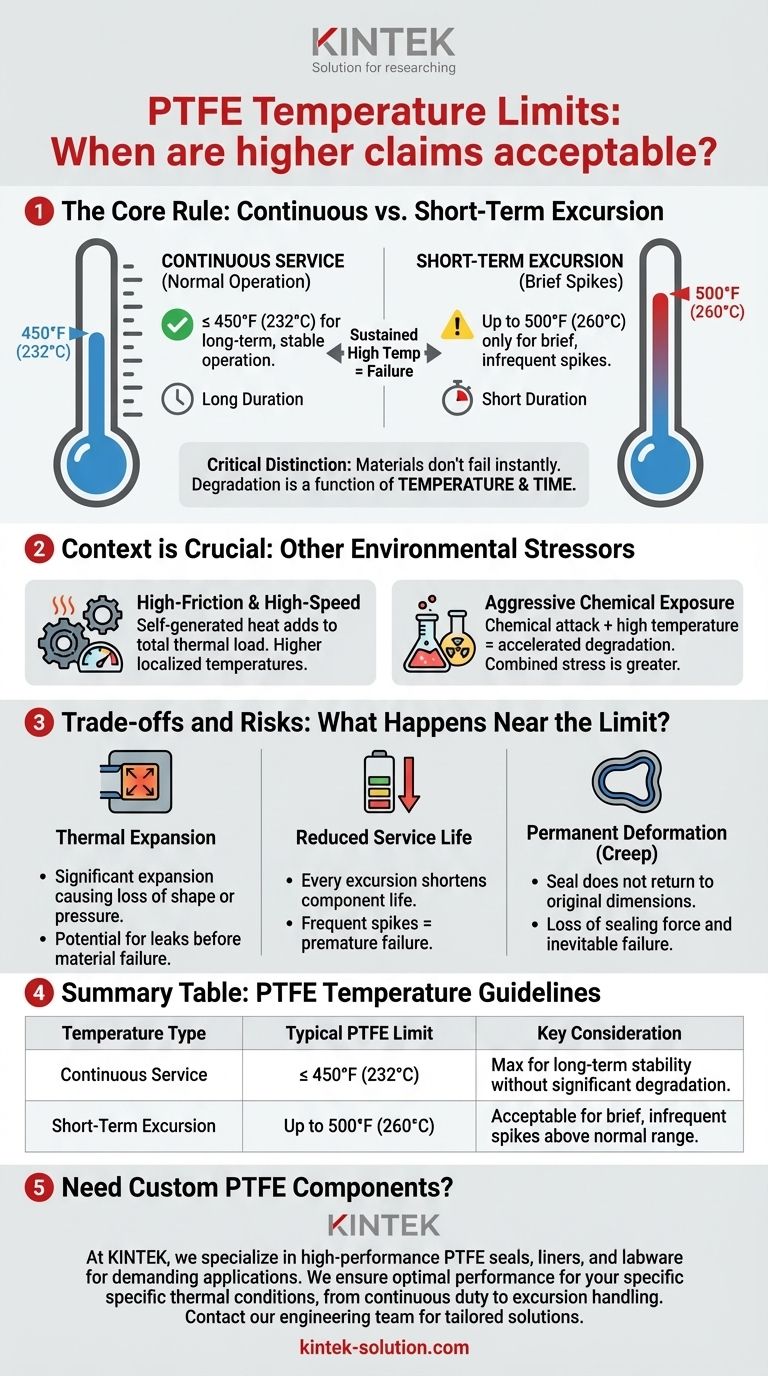

In short, the higher claimed temperature limits for PTFE are acceptable only for brief, intermittent temperature "upsets" or spikes, not for continuous, normal operation. A system that typically runs at or below 450°F (232°C) could safely use a PTFE component rated for a 500°F (260°C) excursion to handle occasional, short-lived temperature increases.

The critical distinction is between a material's continuous service temperature and its short-term excursion limit. While PTFE can survive brief spikes to higher temperatures, sustained operation near these limits will compromise its integrity and lead to premature failure.

The Difference Between Continuous and Excursion Temperatures

To properly specify a material like PTFE, you must understand the nature of the thermal load it will experience. The datasheet numbers are only meaningful within this context.

Defining Continuous Service Temperature

The continuous service temperature is the maximum temperature a material can withstand for its entire expected service life without significant degradation of its properties.

For standard PTFE, temperature swings should generally remain below 356°F (180°C) for normal, sustained use. This ensures dimensional stability and mechanical integrity over time.

Understanding Temperature Upsets

A temperature upset, or excursion, is a short-duration spike above the normal operating temperature.

PTFE can often handle these brief events. A common and acceptable scenario is a service that runs continuously at 450°F but is designed to tolerate infrequent, short-lived excursions up to 500°F.

Why the Distinction Matters

Materials do not fail instantaneously once a temperature limit is breached. Degradation is a function of both temperature and time.

PTFE can tolerate a brief period at a higher temperature because it doesn't have enough time to undergo significant physical or chemical changes. However, holding it at that same high temperature continuously will accelerate degradation and cause it to fail.

Context is Crucial: Other Environmental Factors

Temperature is not the only factor. PTFE is often chosen for aggressive environments where its unique properties are necessary, and these conditions can affect its thermal performance.

High-Friction and High-Speed Operations

Applications with high friction or speed generate their own localized heat. This self-generated heat must be added to the ambient system temperature when determining the total thermal load on the PTFE component.

Aggressive Chemical Exposure

PTFE's chemical inertness is one of its primary advantages. However, while it resists chemical attack, the combination of aggressive media and high temperatures can be a more significant stressor than either factor alone.

Understanding the Trade-offs and Risks

Pushing any material to its operational limits involves trade-offs. It is critical to understand the consequences of operating near PTFE's upper temperature range.

The Impact of Thermal Expansion

PTFE has a high coefficient of thermal expansion. As temperatures rise, it expands significantly.

Operating continuously above recommended thermal limits (like 180°C) can cause the seal to lose its intended shape or pressure, leading to leaks even before the material itself degrades.

Reduced Service Life

Every temperature excursion shortens the material's life. A seal that experiences frequent spikes to 500°F will not last as long as one that operates at a steady 300°F, even if those spikes are within the material's claimed excursion limit.

Risk of Permanent Deformation

Exceeding the true thermal limits can cause permanent deformation (creep), meaning the seal will not return to its original dimensions once it cools. This results in a loss of sealing force and inevitable failure.

Making the Right Choice for Your Goal

Base your decision on a clear understanding of your system's specific operating conditions, not just the maximum value on a datasheet.

- If your primary focus is maximum reliability and long service life: Operate well within the continuous duty limit, keeping temperatures below 356°F (180°C) wherever possible.

- If your application experiences unavoidable, brief temperature spikes: Select a PTFE component rated for excursions (e.g., 500°F), but ensure the normal operating temperature remains significantly lower (e.g., below 450°F).

- If your environment is both high-temperature and chemically aggressive: Be conservative with your temperature limits to account for the combined stress on the material.

Ultimately, successful design hinges on matching the material's proven capabilities to the full scope of your operational demands.

Summary Table:

| Temperature Type | Typical Limit for PTFE | Key Consideration |

|---|---|---|

| Continuous Service | ≤ 450°F (232°C) | Maximum temperature for long-term, stable operation without significant degradation. |

| Short-Term Excursion | Up to 500°F (260°C) | Acceptable for brief, infrequent temperature spikes above the normal operating range. |

Need PTFE components that can handle your specific temperature profile?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, and labware for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We understand that thermal management is critical to your system's reliability and longevity.

Our expertise ensures that your custom PTFE components are precision-engineered to perform optimally within your exact operating conditions—whether you require robust handling of thermal excursions or maximum service life in continuous duty.

Contact our engineering team today to discuss your application's thermal requirements and receive a solution tailored for peak performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What temperature limitations should be considered when using PTFE lined butterfly valves? Ensure Safe & Reliable Operation

- What are the primary applications of PTFE PCBs? The Ultimate Guide for High-Frequency & Harsh Environments

- What are the key properties of Teflon (PTFE) balls? Essential Guide for Chemical & Thermal Applications

- What additional safety feature do PTFE compensators provide? Prevent Electrical Sparks in Hazardous Environments

- What customization options are available for PTFE sheets? Engineer the Perfect Material for Your Application

- How does the cost of PTFE PCBs compare to FR4 PCBs? A Guide to High-Frequency Material Selection

- What are the properties of 25% glass-filled PTFE bushings? A Guide to Enhanced Strength & Durability

- How do PTFE slide bearings accommodate thermal and seismic movements? Control Structural Movement with Low-Friction Design