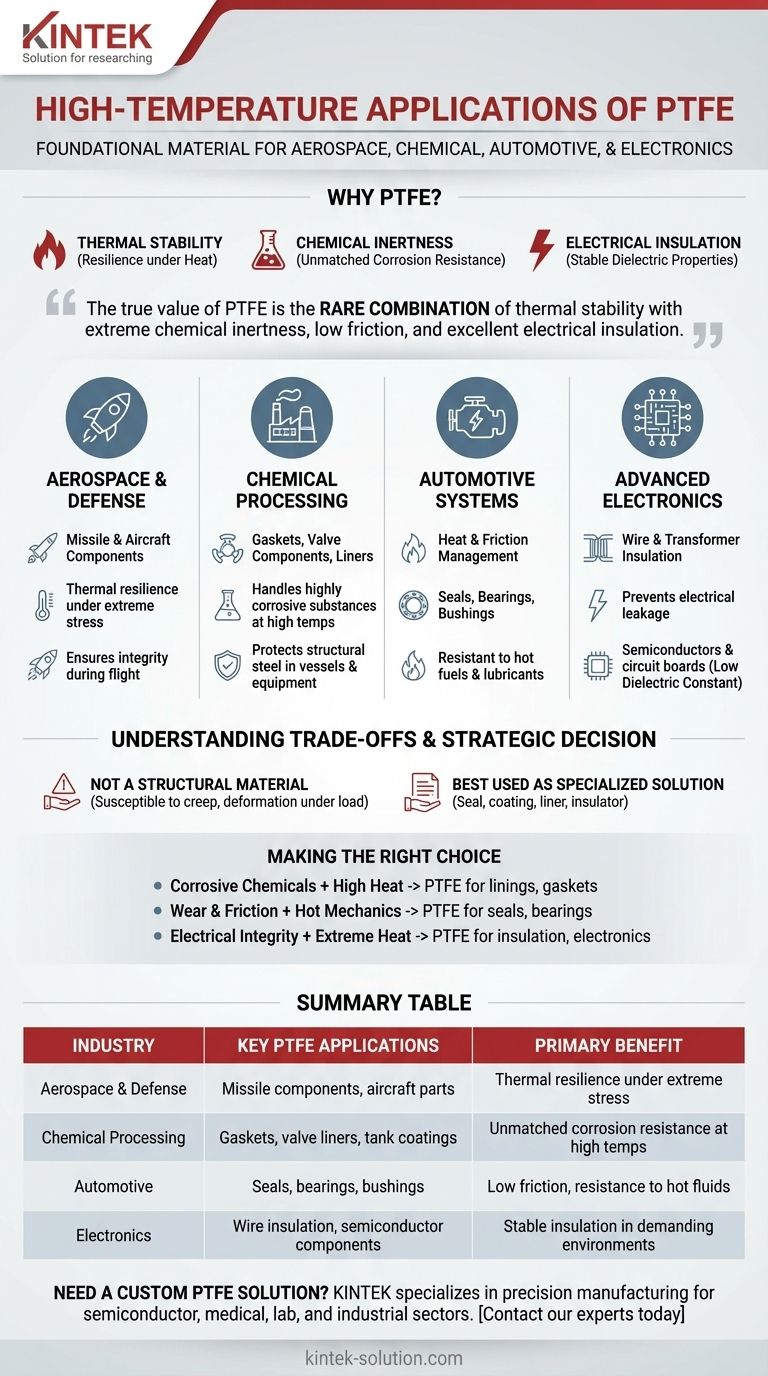

In high-temperature applications, Polytetrafluoroethylene (PTFE) is a foundational material used where other polymers would fail, most notably in the aerospace, chemical processing, automotive, and electronics industries. Its effectiveness stems not just from thermal stability, but from its unique ability to maintain other elite properties—like chemical inertness and electrical insulation—simultaneously at elevated temperatures.

The true value of PTFE in demanding applications isn't just its resistance to heat. It's the rare combination of thermal stability with extreme chemical inertness, low friction, and excellent electrical insulation that makes it indispensable for the most challenging operational environments.

Aerospace and Defense Systems

In aerospace and defense, reliability under extreme conditions is non-negotiable. PTFE's ability to perform under significant thermal stress makes it a critical material.

Components in Missiles and Aircraft

PTFE is specified for components in missiles and aircraft that are exposed to high operational heat. Its thermal resilience ensures that parts maintain their integrity and function during flight and propulsion.

The Chemical and Industrial Processing Backbone

The chemical industry relies on materials that can withstand highly corrosive substances, often at high process temperatures. PTFE is frequently the only viable option.

Unmatched Corrosion Resistance at Temperature

PTFE is used to make gaskets, valve components, and industrial pipeline liners. It handles highly reactive and corrosive chemicals that would quickly degrade metals, glass, and other plastics, especially when heat is added to the system.

Linings for Vessels and Equipment

It serves as a lining for distillation towers, heat exchangers, kettles, and tanks. In these applications, the PTFE layer protects the structural steel from chemical attack, enabling safe and continuous industrial processes at high temperatures.

High-Performance Automotive Systems

Modern automotive engines and systems operate at high temperatures and require components that are durable and efficient. PTFE's properties solve several key challenges.

Heat and Friction Management

In the automotive industry, PTFE is valued for its combined high heat resistance and low friction. This makes it ideal for seals, bearings, and bushings where it reduces wear and tear on moving parts near hot engine components.

Resistance to Aggressive Fluids

Its chemical resistance is also critical for parts exposed to hot fuels and lubricants. PTFE ensures components do not degrade, swell, or fail when in constant contact with these aggressive fluids under thermal stress.

Advanced Electronics and Electrical Insulation

As electronics become more powerful and compact, managing heat is a primary concern. PTFE's electrical properties are remarkably stable even at high temperatures.

Stable Insulation for Wires and Transformers

PTFE is a superior electrical insulator used for high-performance wire insulation and in insulated transformers. It prevents electrical leakage and short circuits without breaking down or melting in thermally demanding electronic environments.

Components for Semiconductors

Its low dielectric constant and thermal stability make it ideal for use in semiconductors and circuit boards. These properties are essential for maintaining signal integrity and component reliability in electronics operating under extreme conditions.

Understanding the Trade-offs

While its combination of properties is exceptional, selecting PTFE requires understanding its context. It is not a universal solution for all high-temperature problems.

Not a High-Strength Structural Material

PTFE is a relatively soft material and is susceptible to creep, or deformation under a sustained load. While it withstands high temperatures, it is not typically used for primary load-bearing structural components, especially when under mechanical stress.

Best Used as a Specialized Solution

Its primary value is as a seal, coating, liner, or insulator. In these roles, it enables other structural materials (like steel or aluminum) to function in environments they otherwise could not survive. The design leverages PTFE for its surface properties, not its bulk strength.

Making the Right Choice for Your Application

Choosing PTFE is a strategic decision based on the specific combination of challenges you need to overcome.

- If your primary focus is handling corrosive chemicals at high temperatures: PTFE is an unparalleled choice for linings, gaskets, and transport pipes in the chemical processing industry.

- If your primary focus is reducing wear and friction in a hot mechanical system: Its low friction and thermal stability make it ideal for seals, bearings, and bushings in automotive and industrial machinery.

- If your primary focus is maintaining electrical integrity in extreme heat: PTFE is a superior material for high-frequency wire insulation, transformers, and critical electronic components.

Ultimately, selecting PTFE is a strategic decision for environments where a combination of heat, chemical, and electrical stresses would cause nearly any other polymer to fail.

Summary Table:

| Industry | Key PTFE Applications | Primary Benefit |

|---|---|---|

| Aerospace & Defense | Missile components, aircraft parts | Thermal resilience under extreme stress |

| Chemical Processing | Gaskets, valve liners, tank coatings | Unmatched corrosion resistance at high temperatures |

| Automotive | Seals, bearings, bushings | Low friction and resistance to hot, aggressive fluids |

| Electronics | Wire insulation, semiconductor components | Stable electrical insulation in thermally demanding environments |

Need a custom PTFE solution for your high-temperature application?

KINTEK specializes in the precision manufacturing of high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine expert material knowledge with custom fabrication capabilities, from prototypes to high-volume orders, to ensure your components perform reliably under extreme heat and chemical stress.

Contact our experts today to discuss how we can enhance your project's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts