In its most basic forms, Polytetrafluoroethylene (PTFE) is supplied as a raw material, such as granular powder for molding or liquid dispersion for coatings. It is also available in semi-finished stock shapes like rods, sheets, and films for machining. Its common uses are exceptionally diverse, ranging from non-stick cookware and electrical wire insulation to industrial bearings and chemically resistant pipe linings, all driven by its unique combination of properties.

PTFE's true value lies not just in its inherent properties—low friction, chemical inertness, and heat resistance—but in the variety of forms it can be supplied in, allowing it to be integrated as a coating, a solid part, or a performance-enhancing additive.

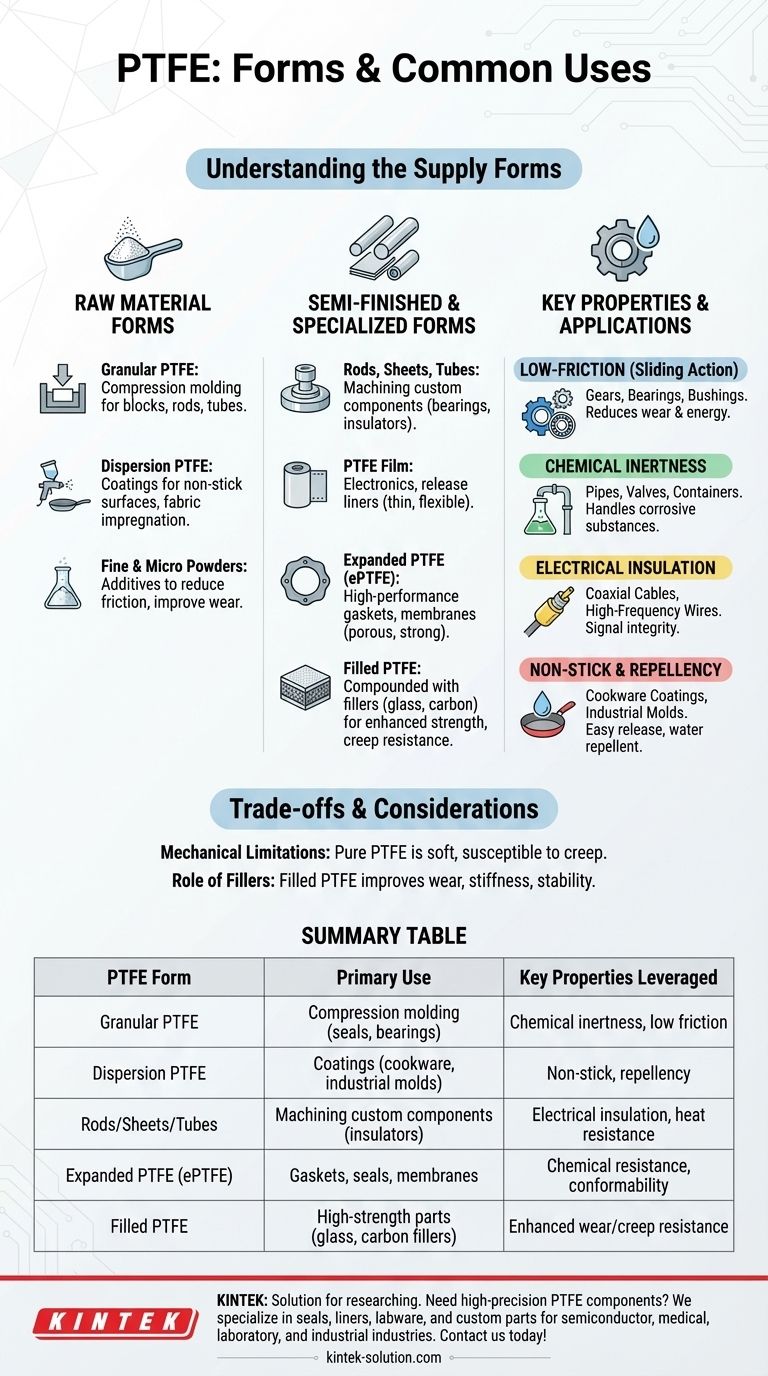

Understanding the Supply Forms of PTFE

To select the right material, you must first understand how it is produced and supplied. PTFE is available in several fundamental forms, each tailored for different manufacturing processes and end-use applications.

Raw Material Forms

These are the foundational forms of PTFE used to create other products.

- Granular PTFE: This is a primary raw material, often used in compression molding to create solid blocks, rods, and tubes which are then machined into finished parts.

- Dispersion PTFE: This consists of fine PTFE particles suspended in liquid. It is primarily used to create coatings on metal for non-stick surfaces or to impregnate fabrics like fiberglass.

- Fine & Micro Powders: These powders are designed to be used as an additive. They are blended into other materials, such as plastics, elastomers, or lubricants, to reduce their coefficient of friction and improve wear resistance.

Semi-Finished and Specialized Forms

These forms are often the starting point for fabrication and engineering.

- Rods, Sheets, and Tubes: These are the most common semi-finished shapes. Engineers and machinists use these stock materials to create custom components like bearings, seals, and insulators.

- PTFE Film: This thin, flexible sheet is valued for its non-stick surface and excellent dielectric properties, making it useful in electronics and as a release liner in industrial processes.

- Expanded PTFE (ePTFE): This is a porous, strong material created by expanding PTFE. It is commonly used for high-performance gaskets, seals, and waterproof, breathable membranes in textiles.

- Filled PTFE: To enhance specific properties, PTFE is often compounded with fillers like glass fiber, carbon, or bronze. This improves mechanical strength, creep resistance, and thermal conductivity.

Key Applications Driven by Core Properties

The widespread use of PTFE is a direct result of its remarkable combination of characteristics. Each application leverages one or more of these core properties.

For Low-Friction and Sliding Action

PTFE has one of the lowest coefficients of friction of any solid material.

This makes it an ideal choice for applications requiring smooth, sliding motion, such as gears, bearings, bushings, and slide plates, where it reduces wear and energy consumption.

For Chemical Inertness

PTFE is non-reactive to nearly all chemicals and solvents.

This exceptional resistance makes it indispensable in the chemical processing and oil & gas industries for lining pipes, valves, and containers that handle corrosive or reactive substances.

For Electrical Insulation

PTFE is an excellent electrical insulator with a high dielectric strength.

It is widely used in computer and aerospace applications for insulating coaxial cables and high-frequency hookup wires where signal integrity is critical.

For Non-Stick and Repellency

The high-energy bond between its carbon and fluorine atoms gives PTFE its famous non-stick surface.

This property is leveraged for cookware coatings, industrial molds, and water-repellent membranes in performance outerwear.

The Trade-offs and Considerations

While incredibly versatile, PTFE is not the solution for every problem. Understanding its limitations is critical for proper material selection.

Mechanical Limitations

Pure, or "virgin," PTFE is relatively soft and can be susceptible to creep—the tendency to deform under sustained load. Its wear resistance may also be insufficient for high-load mechanical applications.

The Role of Fillers

This is precisely why filled PTFE compounds were developed. Adding fillers like glass or carbon dramatically improves wear resistance, stiffness, and dimensional stability, though it may slightly reduce chemical resistance or increase the coefficient of friction.

Environmental and Health Context

PTFE is a fluoropolymer, a type of per- and polyfluoroalkyl substance (PFAS). The manufacturing and disposal of some PFAS chemicals are under scrutiny for environmental and health reasons, making it important to be aware of the material's lifecycle and relevant regulations in your industry.

Making the Right Choice for Your Application

Selecting the correct form of PTFE depends entirely on your end goal.

- If your primary focus is machining a custom component: Start with semi-finished PTFE rods or sheets, selecting a filled grade if you need enhanced mechanical strength.

- If your primary focus is creating a non-stick surface: Your best option is a PTFE dispersion for coating or a bonded PTFE film.

- If your primary focus is reducing friction in a composite material: Use fine or micro powder PTFE as a performance-enhancing additive in your base material.

- If your primary focus is sealing a joint in a harsh chemical environment: Expanded PTFE (ePTFE) provides excellent conformability and chemical resistance for gasketing.

Ultimately, understanding both the form and function of PTFE is the key to leveraging its unique capabilities for any engineering challenge.

Summary Table:

| PTFE Form | Primary Use | Key Properties Leveraged |

|---|---|---|

| Granular PTFE | Compression molding for machined parts (seals, bearings) | Chemical inertness, low friction |

| Dispersion PTFE | Coatings for non-stick surfaces (cookware, industrial molds) | Non-stick, repellency |

| Rods/Sheets/Tubes | Machining custom components (insulators, bushings) | Electrical insulation, heat resistance |

| Expanded PTFE (ePTFE) | Gaskets, seals, membranes | Chemical resistance, conformability |

| Filled PTFE | High-strength parts (with glass, carbon, bronze fillers) | Enhanced wear/creep resistance |

Need high-precision PTFE components tailored to your application? KINTEK specializes in manufacturing PTFE seals, liners, labware, and custom parts for semiconductor, medical, laboratory, and industrial industries. We combine precision production with custom fabrication—from prototypes to high-volume orders—ensuring your components meet exact performance requirements. Contact us today to discuss your PTFE needs and leverage our expertise for reliable, industry-grade solutions!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does PTFE's coefficient of friction compare to other plastics? Unmatched Low-Friction Performance

- What are some alternative materials to Teflon (PTFE)? Find the Right Fluoropolymer for Your Needs

- What are the different formulations of PTFE available? Find the Right PTFE for Your Application

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- What is Glass-Filled PTFE and what are its properties? A Guide to Enhanced PTFE Performance

- What is the water absorption rate of PTFE after 24 hours? Unlock Unmatched Material Stability

- How is PTFE utilized in the electronics and electrical industry? Essential for High-Frequency & Harsh Environments

- What are the general material properties of PTFE? Discover Its Extreme Chemical & Thermal Resistance