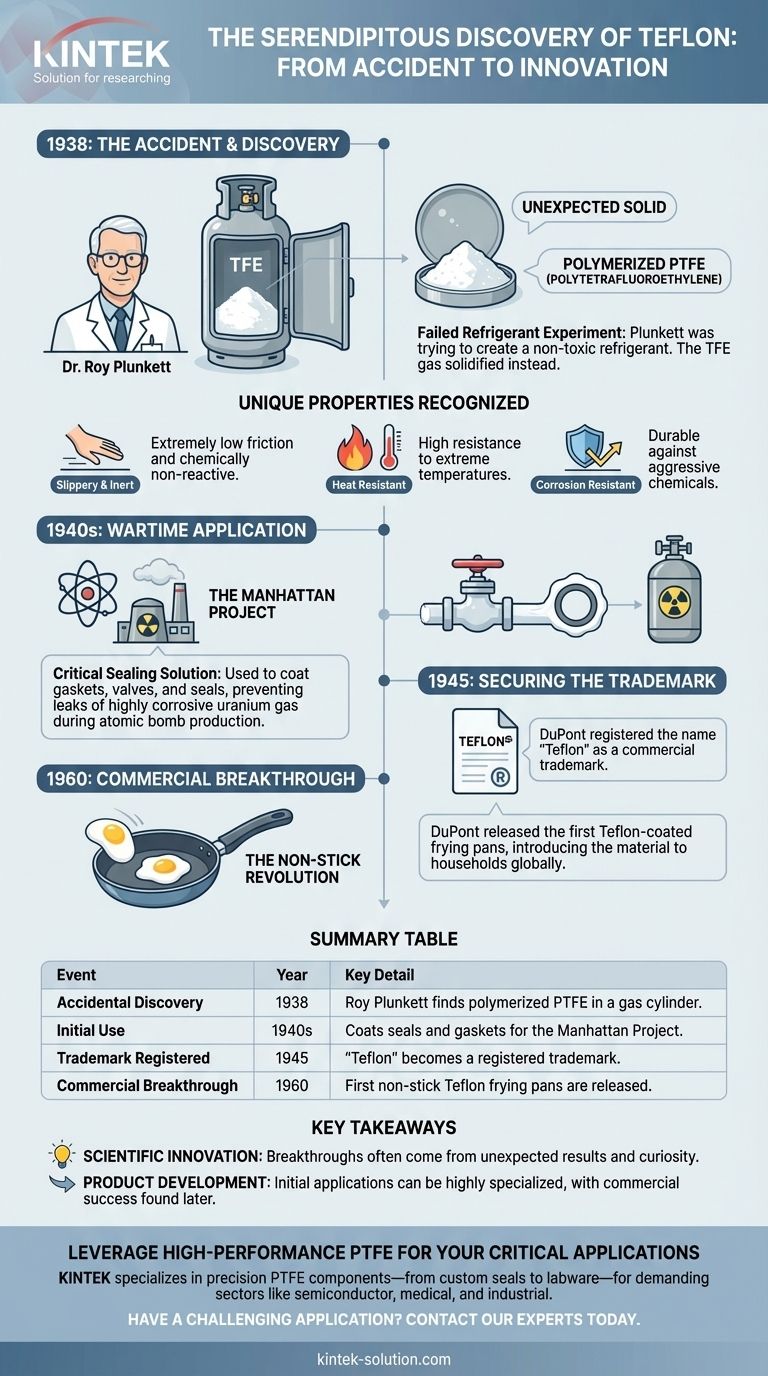

The discovery of Teflon was a complete accident. In 1938, chemist Roy Plunkett at DuPont was experimenting with refrigerant gases when a canister of tetrafluoroethylene gas unexpectedly solidified into a strange, waxy white powder. Instead of being used for refrigeration, its first major application was as a highly corrosion-resistant coating for materials in the Manhattan Project during World War II.

Teflon’s journey from a surprising laboratory mistake to a critical component in top-secret military technology demonstrates how accidental discoveries can find their purpose in solving the most demanding challenges of their time.

The Accidental Discovery

A Failed Refrigerant Experiment

In 1938, Dr. Roy J. Plunkett was working to create a new, non-toxic refrigerant for E.I. du Pont de Nemours and Company (DuPont). His work involved using tetrafluoroethylene (TFE), a gas stored in pressurized cylinders.

An Unexpected Solid

On one occasion, Plunkett and his assistant opened the valve on a cylinder of TFE, but no gas came out, even though the canister's weight indicated it was still full. Puzzled, they sawed the cylinder open.

Inside, they discovered that the TFE gas had polymerized—its individual molecules had linked together to form a waxy, white solid. This new substance was polytetrafluoroethylene, or PTFE.

Recognizing Unique Properties

Plunkett and his team quickly realized this was no ordinary material. It was incredibly slippery and inert, meaning it did not react with other chemicals. It was also highly resistant to heat and corrosion, properties that would soon prove to be invaluable.

From Laboratory to Wartime Application

The Manhattan Project's Challenge

The first significant use for Plunkett's discovery was not in a kitchen, but in the war effort. During World War II, scientists on the Manhattan Project needed to handle highly corrosive uranium hexafluoride gas to produce enriched uranium for the atomic bomb.

A Critical Sealing Solution

This aggressive gas destroyed nearly every material it touched. The new polymer, however, was one of the few substances that could resist it.

DuPont, which had patented the material in 1941, used it to coat gaskets, valves, and seals. This application was critical to preventing leaks and enabling the uranium enrichment process to proceed safely and effectively.

The Path to the Public

Securing the Trademark

After its secret wartime use, DuPont registered the name Teflon as a commercial trademark in 1945. However, the material was expensive and a widespread public use was not yet apparent.

The Non-Stick Revolution

The idea of using Teflon for cookware came much later. It wasn't until 1960 that DuPont released the first non-stick frying pans coated with Teflon, finally bringing the accidental discovery into homes around the world.

This move transformed the material from a niche industrial and military product into a household name.

Key Takeaways from Teflon's Origin

- If your primary focus is on scientific innovation: Recognize that some of the most important breakthroughs are born from accidents and the curiosity to investigate unexpected results.

- If your primary focus is on product development: Understand that a material's first application may be highly specialized, while its ultimate commercial success could lie in a completely different market discovered years later.

Ultimately, the story of Teflon is a powerful reminder that serendipity plays a fundamental role in scientific and technological progress.

Summary Table:

| Event | Year | Key Detail |

|---|---|---|

| Accidental Discovery | 1938 | Roy Plunkett finds polymerized PTFE in a gas cylinder. |

| Patent Filed | 1941 | DuPont patents the new polymer. |

| Initial Use | 1940s | Coats seals and gaskets for the Manhattan Project. |

| Trademark Registered | 1945 | "Teflon" becomes a registered trademark. |

| Commercial Breakthrough | 1960 | First non-stick Teflon frying pans are released. |

Leverage High-Performance PTFE for Your Critical Applications

The story of Teflon shows how a material's unique properties can solve extreme challenges. At KINTEK, we specialize in precision PTFE components—from custom seals and liners to complex labware—that meet the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a prototype or high-volume production, our expertise ensures superior chemical resistance, thermal stability, and performance.

Have a challenging application? Contact our experts today to discuss your custom PTFE solution.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss