To properly maintain PTFE sheets, you must focus on three core activities: regularly inspecting the material for any signs of wear or degradation, cleaning the surface exclusively with mild detergents and water, and storing it away from direct sunlight and extreme temperatures to prevent environmental damage. This proactive approach ensures the material retains its unique low-friction and chemical-resistant properties.

The goal of PTFE maintenance is not to repair the material, but to preserve its inherent properties. Effective maintenance is a defensive strategy, protecting the sheet from the two things that can compromise it: physical damage and environmental degradation.

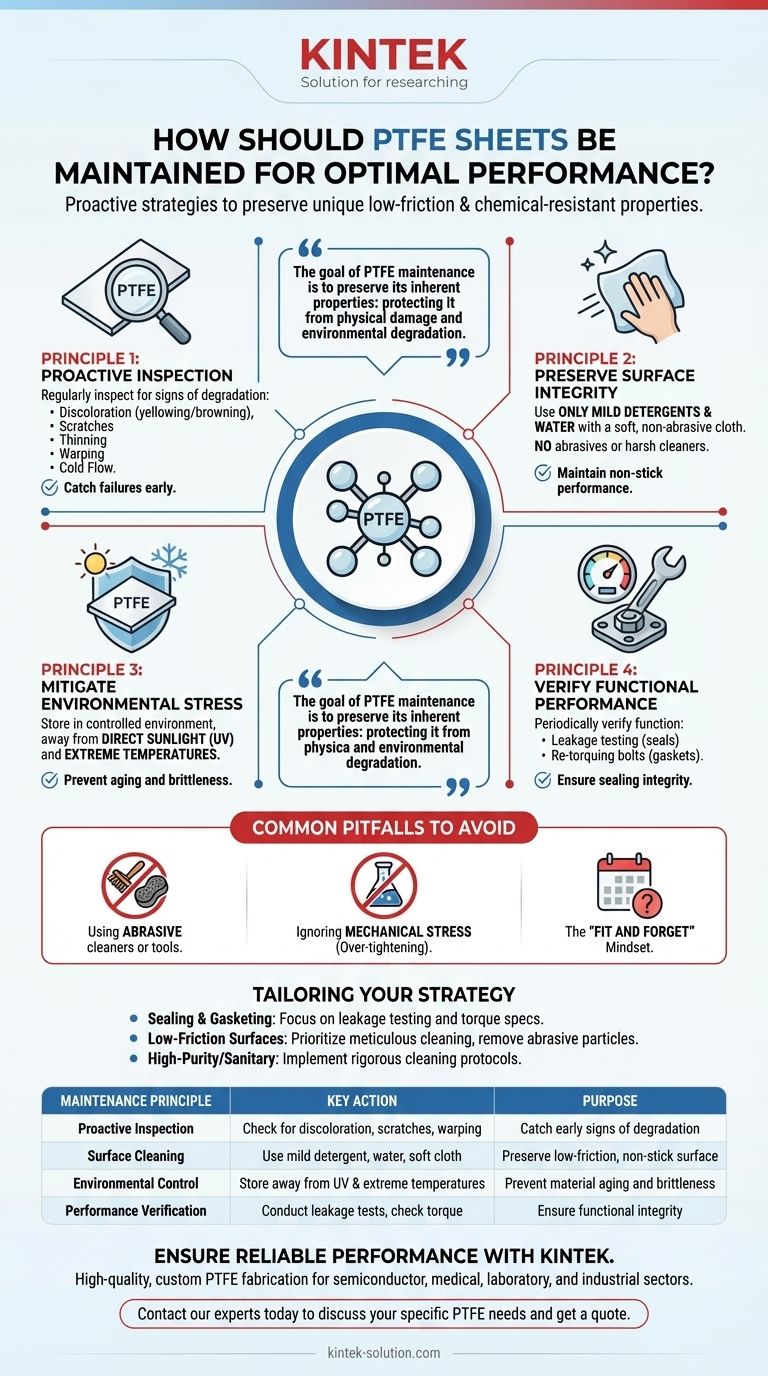

The Core Principles of PTFE Maintenance

Polytetrafluoroethylene (PTFE) is valued for its extreme inertness and low coefficient of friction. A successful maintenance plan is built on protecting these characteristics from external forces.

Principle 1: Proactive Inspection is Non-Negotiable

You must regularly inspect PTFE components to catch potential failures before they occur. This is especially critical in high-stress or high-purity applications.

Look for specific indicators of degradation, such as discoloration (yellowing or browning), surface scratches, thinning, or any physical deformation like warping or extrusion (cold flow). These are early warnings that the material's integrity is compromised.

Principle 2: Preserve the Surface Integrity

The low-friction, non-stick surface is PTFE's primary asset. The goal of cleaning is to remove contaminants without altering this surface.

Use only mild detergents and water. Gently wipe the surface with a soft, non-abrasive cloth. This removes residue without creating the micro-scratches that can lead to premature wear and loss of non-stick performance.

Principle 3: Mitigate Environmental Stress

PTFE is durable, but not indestructible. Long-term exposure to certain environmental factors can degrade the polymer.

When not in use, sheets and components should be stored in a controlled environment. Protect them from direct sunlight (UV radiation) and extreme temperatures, as both can accelerate aging and make the material brittle over time.

Principle 4: Verify Functional Performance

Visual inspection is only part of the story. For applications like gaskets and seals, you must periodically verify that the component is still performing its function.

This can involve leakage testing for seals or re-torquing bolts on flanged joints to ensure proper compression is maintained. This confirms the material’s sealing integrity under operational conditions.

Common Pitfalls to Avoid

Mistakes in PTFE maintenance often stem from treating it like a more conventional material. Understanding what not to do is as important as knowing what to do.

The Danger of Abrasives and Harsh Chemicals

Never use abrasive cleaners, scouring pads, or metal brushes. These tools will permanently damage the PTFE surface, destroying its low-friction properties and creating sites for contamination to adhere.

While PTFE is highly chemically resistant, avoid using aggressive solvents for cleaning unless specified by the manufacturer. Mild detergent is sufficient and safer.

Ignoring Signs of Mechanical Stress

PTFE can deform under excessive mechanical stress, a phenomenon known as "cold flow." Over-tightening a PTFE gasket, for example, can cause it to squeeze out of the flange, leading to seal failure.

Maintenance should include inspecting the surrounding assembly to ensure it is not placing undue stress on the PTFE component.

The "Fit and Forget" Mindset

Because PTFE is so reliable, it is often installed and forgotten. This is a mistake. The most effective approach is to adhere to a regular maintenance schedule.

This schedule should be based on the demands of the application, with more frequent inspections for high-pressure, high-temperature, or critical sealing uses.

How to Apply This to Your Project

Your maintenance strategy should be tailored to the primary function of the PTFE component in your system.

- If your primary focus is sealing and gasketing: Your priority is routine leakage testing and ensuring bolts remain at their proper torque specification to prevent cold flow.

- If your primary focus is low-friction surfaces (e.g., slide bearings): Your priority is keeping the surface meticulously clean and free of abrasive particles that could score the material.

- If your primary focus is high-purity or sanitary applications: Your priority is implementing a rigorous cleaning protocol to eliminate any potential for contamination, in addition to standard visual inspection.

Ultimately, maintaining PTFE is about respecting the material's properties and systematically protecting them from harm.

Summary Table:

| Maintenance Principle | Key Action | Purpose |

|---|---|---|

| Proactive Inspection | Check for discoloration, scratches, warping | Catch early signs of degradation |

| Surface Cleaning | Use mild detergent, water, and soft cloth | Preserve low-friction, non-stick surface |

| Environmental Control | Store away from UV light and extreme temperatures | Prevent material aging and brittleness |

| Performance Verification | Conduct leakage tests and check torque | Ensure functional integrity in application |

Ensure your PTFE components perform reliably for years to come. Proper maintenance is key, but it starts with high-quality, precision-manufactured parts. At KINTEK, we specialize in custom PTFE fabrication—from prototypes to high-volume orders—for the semiconductor, medical, laboratory, and industrial sectors. Our components are built to last, simplifying your maintenance routine and maximizing uptime.

Contact our experts today to discuss your specific PTFE needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance