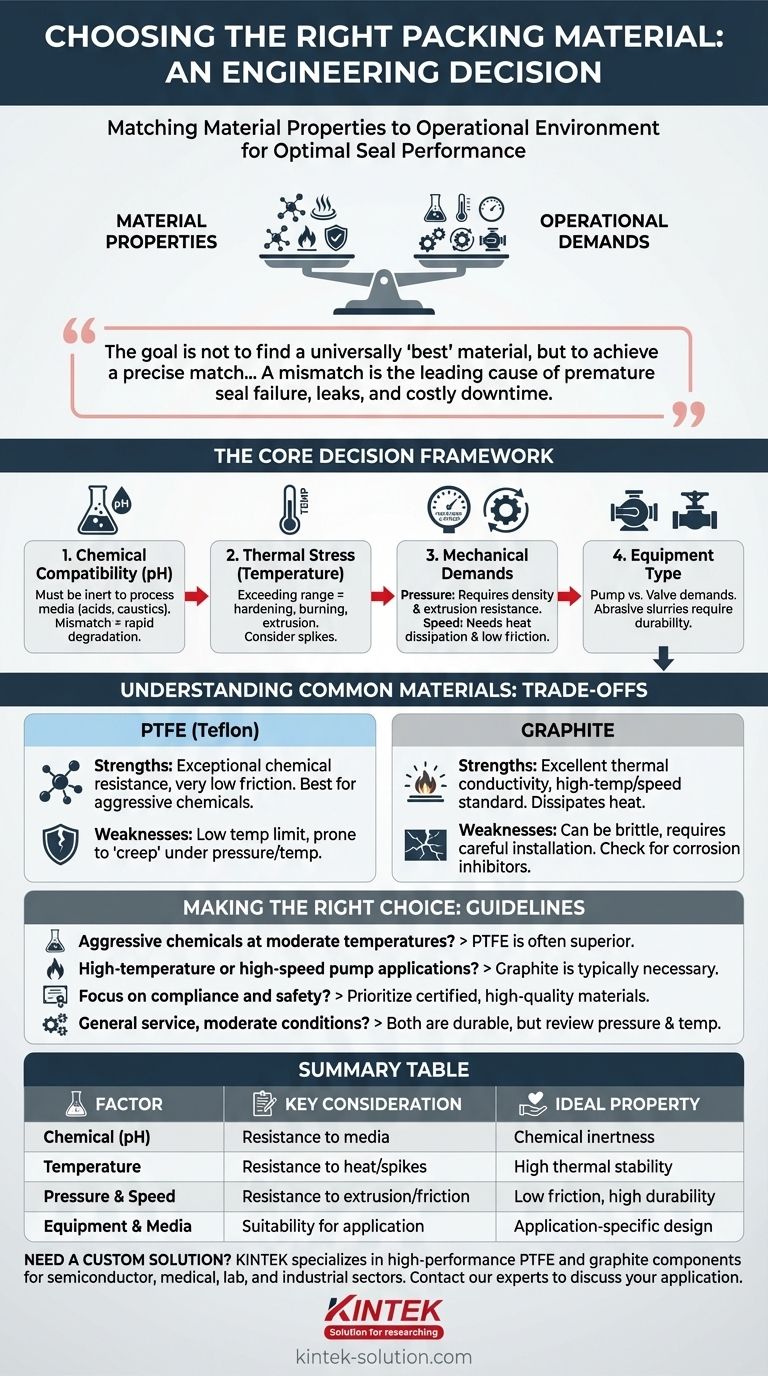

Choosing the right packing material is a critical engineering decision that hinges on a systematic evaluation of your application's specific operational demands. The selection process requires a clear analysis of key factors including the chemical environment (pH), operating temperature, internal pressure, and mechanical stresses like shaft speed.

The goal is not to find a universally "best" material, but to achieve a precise match between the packing's properties and the equipment's operational environment. A mismatch is the leading cause of premature seal failure, leaks, and costly downtime.

The Core Decision Framework: Matching Material to Mission

Selecting the correct packing material begins not with the material itself, but with a thorough analysis of the environment where it will operate. Each factor acts as a filter, narrowing your options to the most suitable candidates.

Analyzing Chemical Compatibility (pH)

The first filter is chemical resistance. The packing must be inert to the fluid, gas, or slurry it is sealing.

A material that is incompatible with the process media will degrade rapidly, losing its ability to seal. Pay close attention to the pH value, as highly acidic or alkaline environments require specialized materials.

Evaluating Thermal Stress (Temperature)

Every packing material has a defined operating temperature range. Exceeding this limit will cause the material to harden, burn, or extrude, resulting in immediate seal failure.

Consider both the consistent operating temperature and any potential temperature spikes during operation or cleaning cycles. Materials like graphite excel in high-temperature services, while others like PTFE have more limited thermal thresholds.

Assessing Mechanical Demands (Pressure & Speed)

The mechanical forces exerted on the packing are a primary cause of wear. You must account for two key forces:

- Pressure: In static applications like valves, high pressure requires a denser, more extrusion-resistant packing.

- Shaft Speed: In dynamic applications like pumps, high rotational speeds generate significant frictional heat. This requires a packing with excellent heat dissipation and a low coefficient of friction to prevent the shaft from scoring and the packing from burning.

Considering the Equipment Type

The design of the equipment influences the type of packing required. A pump's rotating shaft places different demands on a packing than a valve's reciprocating stem.

Furthermore, the media itself is a factor. Abrasive slurries require a tougher, more durable packing than clean water or gas to resist wear.

Understanding the Trade-offs of Common Materials

While many packing variants exist, most decisions involve choosing between or combining two foundational materials: PTFE and Graphite. Understanding their inherent strengths and weaknesses is key to making an informed choice.

The Case for PTFE (Teflon)

PTFE is renowned for its exceptional chemical resistance and extremely low friction.

It is often the go-to choice for applications involving aggressive chemicals, such as strong acids and caustics. However, standard PTFE has a relatively low temperature limit and can be prone to "creep" or cold flow under high pressure and temperature.

The Case for Graphite

Graphite-based packings are the standard for high-temperature and high-speed applications.

Its excellent thermal conductivity allows it to pull heat away from the shaft, reducing the risk of failure. While it conforms well to sealing surfaces, it can be more brittle than PTFE and requires care during installation. In certain conditions, it's also important to select a grade with corrosion inhibitors to prevent galvanic action with stainless steel components.

Quality and Certifications Matter

Beyond the base material, always verify the quality of the packing. Procure materials from reputable suppliers who can provide test results and certifications.

For industries like food processing or pharmaceuticals, using packing that meets specific regulatory standards is not just best practice—it is a requirement for ensuring the safety of personnel and consumers.

Making the Right Choice for Your Application

Use these guidelines to steer your final decision based on your primary operational challenge.

- If your primary focus is aggressive chemicals at moderate temperatures: PTFE packing is often the superior choice due to its near-universal chemical inertness.

- If your primary focus is high-temperature or high-speed pump applications: Graphite packing is typically necessary for its unmatched thermal stability and heat dissipation.

- If your primary focus is compliance and safety: Always prioritize procuring high-quality packings with the necessary tests and certifications for your specific industry and media.

- If your primary focus is general service with moderate conditions: Both PTFE and graphite are durable, cost-effective options, but the final choice must still align with a careful review of your pressure, temperature, and media.

A systematic evaluation of these factors moves your decision from a guess to an engineering certainty.

Summary Table:

| Selection Factor | Key Consideration | Ideal Material Property |

|---|---|---|

| Chemical Compatibility (pH) | Resistance to acidic/alkaline media | Chemical inertness |

| Operating Temperature | Resistance to heat and thermal spikes | High thermal stability |

| Pressure & Shaft Speed | Resistance to extrusion and friction | Low coefficient of friction, high durability |

| Equipment & Media Type | Suitability for pumps, valves, or abrasive slurries | Application-specific design |

Need a custom packing solution that matches your exact operational demands?

KINTEK specializes in manufacturing high-performance PTFE and graphite components, including seals and packings, for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders.

Contact our experts today to discuss your application's specific chemical, thermal, and mechanical requirements. Let us help you achieve a perfect seal, enhance equipment longevity, and eliminate costly downtime.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- When and by whom was PTFE discovered? A Tale of Accidental Innovation