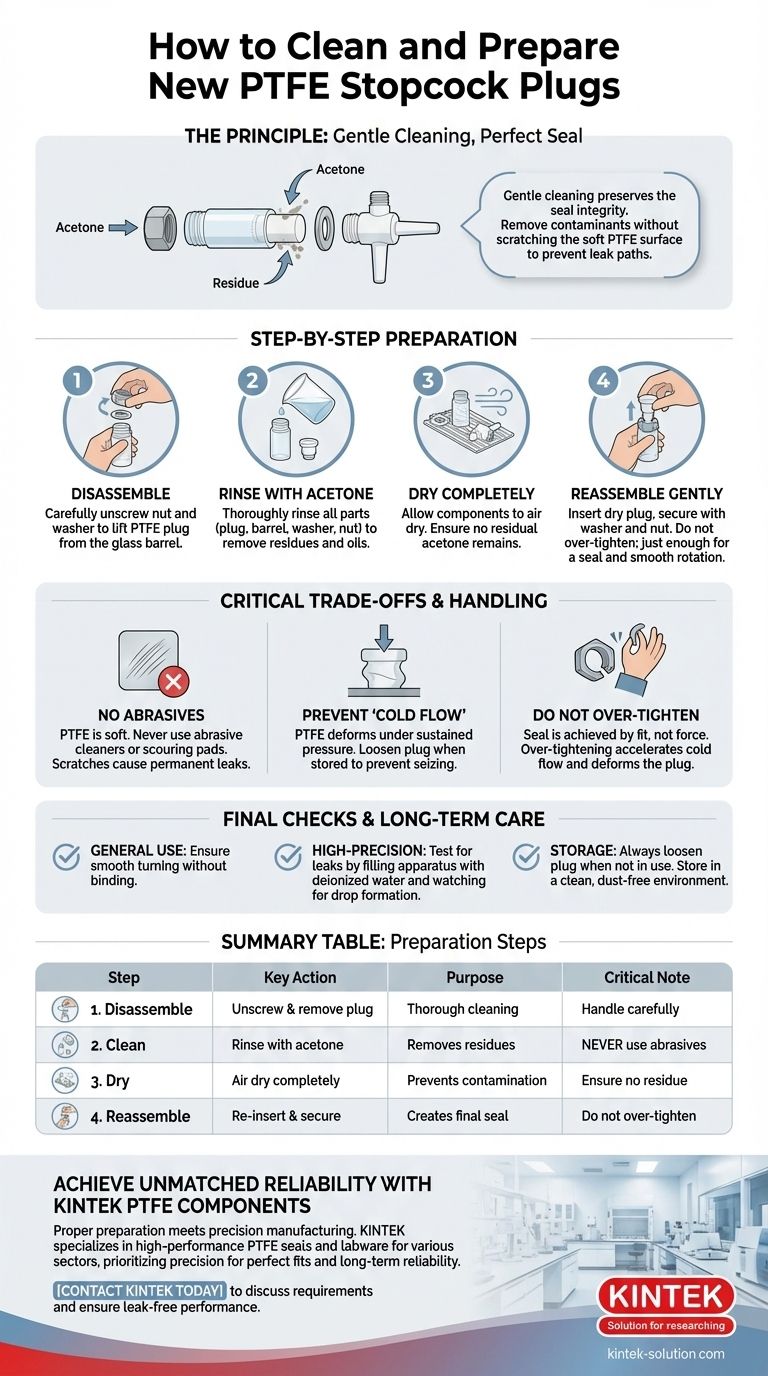

To prepare a new PTFE stopcock plug for use, you must first disassemble it from the glass barrel. Rinse both the PTFE plug and the inner glass barrel with acetone to remove any manufacturing residues. Once completely dry, reassemble the components, and the stopcock is ready for use without any lubricant.

The core principle is gentle cleaning to preserve the integrity of the seal. The goal is to remove contaminants from the manufacturing process without scratching the soft PTFE surface, as even microscopic damage can create a leak path.

The Principle of Preparation: Removing Residue, Preserving the Seal

A new stopcock is not ready for immediate use. Proper preparation is essential to ensure it functions as a reliable, leak-free seal from the very first experiment.

Why Clean a New Stopcock?

New laboratory equipment, including PTFE components, often carries residual materials from the manufacturing process. These can include mold release agents, machine oils, or fine particulate matter from packaging and transport.

Failing to remove these contaminants can lead to contamination of your reagents or prevent the stopcock from forming a perfect, leak-free seal.

The Role of Acetone

Acetone is the recommended solvent for this task. It is effective at dissolving common organic residues and evaporates quickly without leaving a film.

Crucially, acetone is chemically compatible with both the borosilicate glass of the barrel and the inert PTFE of the plug, ensuring it cleans without causing damage.

The Step-by-Step Process

- Disassemble: Carefully unscrew the retaining nut and washer, allowing you to lift the PTFE plug straight out of the glass barrel.

- Rinse: Thoroughly rinse all parts—the plug, barrel, washer, and nut—with acetone.

- Dry: Allow the components to air dry completely. Ensure no residual acetone remains, as it could interfere with your subsequent work.

- Reassemble: Insert the dry plug back into the barrel, then secure it with the washer and retaining nut. The nut should be tightened just enough to create a seal and allow for smooth rotation, not torqued down.

Understanding the Critical Trade-offs

The reliability of a PTFE stopcock depends entirely on how it is handled. Its material properties introduce specific vulnerabilities that you must manage.

The "No Abrasives" Rule

PTFE is significantly softer than glass. Never use abrasive cleaners, powders, or scouring pads on either the plug or the glass barrel.

Scratches on the PTFE plug or the inner glass barrel create micro-channels. These channels will compromise the seal and cause persistent, unfixable leaks, rendering the stopcock useless.

Preventing "Cold Flow" and Seizing

PTFE has a tendency to deform under sustained pressure, a phenomenon known as cold flow. If a stopcock is stored with the plug tightly seated, the PTFE can slowly conform to the shape of the glass barrel.

Over time, this can cause the plug to seize, making it difficult or impossible to turn without risking damage. It can also permanently deform the plug, compromising its ability to seal correctly.

The Risk of Over-tightening

A PTFE stopcock is a "greaseless" design. The seal is achieved by the precise fit between the smooth PTFE plug and the glass barrel, not by applying excessive force.

Over-tightening the retaining nut will not improve the seal. It will only accelerate cold flow, deform the plug, and make the stopcock difficult to operate.

Final Checks and Long-Term Care

Before putting the stopcock into service, ensure it is correctly prepared for its intended function.

- If your primary focus is general use: Ensure the plug turns smoothly without binding or requiring excessive force. The tension should be just enough to hold the plug in place.

- If your primary focus is high-precision work (e.g., titrations): After assembly, test the seal by filling the apparatus (like a burette) with deionized water. Let it stand for several minutes and watch the tip for any drop formation, which indicates a leak.

- If your primary focus is long-term storage: Always loosen the plug within the barrel when the equipment is not in use. Store it in a clean, dust-free environment to prevent particulate contamination.

Proper preparation and handling are the keys to a reliable, leak-free seal for the entire lifespan of your equipment.

Summary Table:

| Step | Key Action | Purpose | Critical Note |

|---|---|---|---|

| 1. Disassemble | Unscrew nut and remove plug from glass barrel. | Allows for thorough cleaning of all components. | Handle carefully to avoid damage. |

| 2. Clean | Rinse plug, barrel, and hardware with acetone. | Removes manufacturing residues (oils, particulates). | Never use abrasives; they can scratch PTFE. |

| 3. Dry | Allow all parts to air dry completely. | Prevents solvent contamination of reagents. | Ensure no acetone residue remains. |

| 4. Reassemble | Re-insert plug and secure with nut. | Creates the final seal. | Do not over-tighten; it can deform the plug. |

Achieve Unmatched Reliability with KINTEK PTFE Components

Proper preparation is the first step to a flawless seal, but it starts with a precision-manufactured component. KINTEK specializes in high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production to ensure a perfect fit and long-term reliability, offering everything from custom prototypes to high-volume orders.

Let us provide the critical components that form the foundation of your process integrity.

Contact KINTEK today to discuss your specific requirements and ensure leak-free performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support