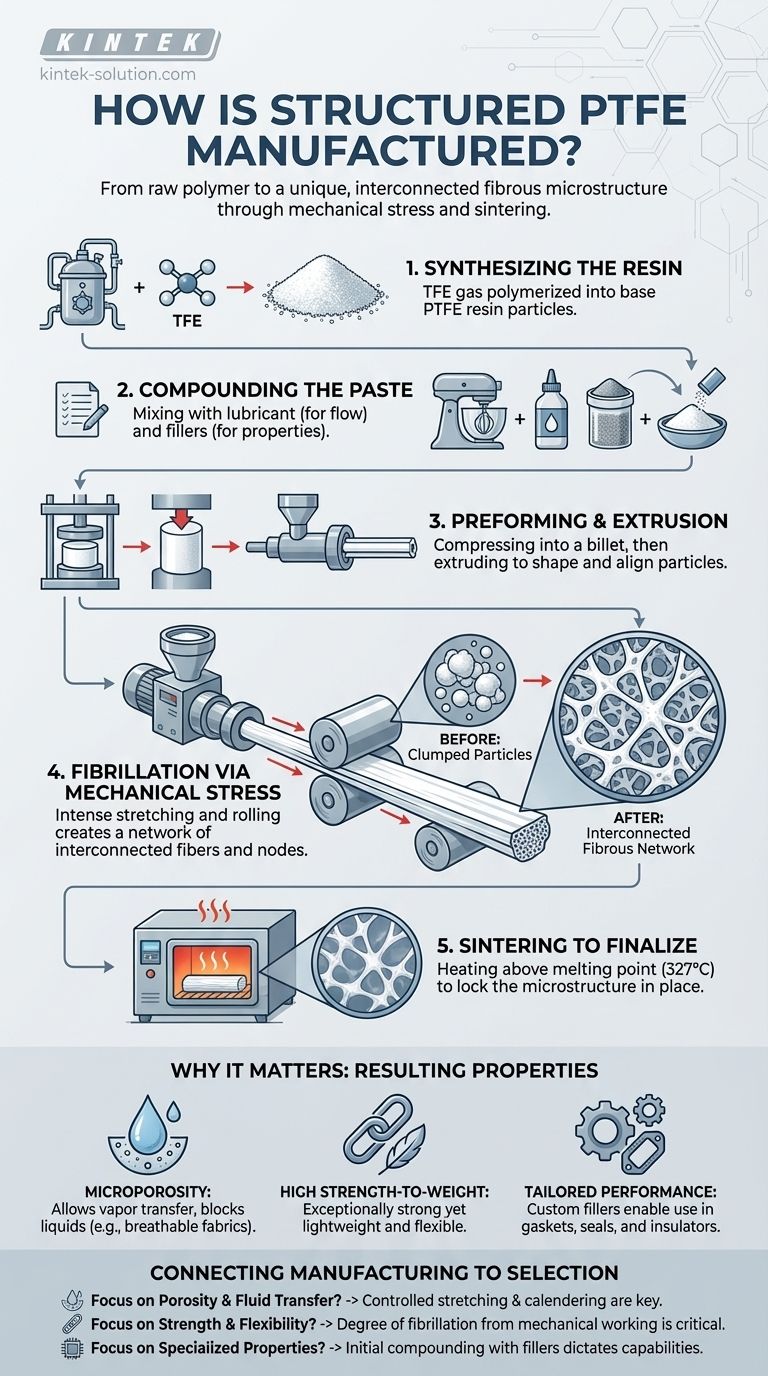

In short, structured PTFE is manufactured by mixing fine PTFE powder with a lubricant, mechanically working this paste through extrusion and stretching to create a specific fibrous network, and then heating it (sintering) to lock that microstructure in place. This process transforms the basic polymer into a material with unique physical properties not found in standard molded PTFE.

The critical insight is that the term "structured" refers not to the base PTFE polymer itself, but to the mechanically-induced microstructure of interconnected fibers and nodes. This structure is created through a specific process of paste extrusion, stretching, and calendering before the material is finalized with heat.

From Raw Polymer to a Usable Form

Before creating the structure, the base Polytetrafluoroethylene (PTFE) resin must be synthesized. This foundational process sets the stage for all subsequent steps.

Step 1: Synthesizing the PTFE Resin

The process begins with common industrial chemicals like fluorspar, hydrofluoric acid, and chloroform. These are heated in a reactor to produce tetrafluoroethylene (TFE) gas, the core building block or monomer.

This TFE gas is then purified and polymerized. It is mixed with water and a catalyst, causing the individual TFE molecules to link together into long chains, forming solid grains of PTFE resin. This raw resin is the starting point for creating the final product.

The Core Process of Creating the Structure

This is where standard PTFE manufacturing diverges to create structured PTFE. The goal is to manipulate the physical form of the resin particles, not just melt them together.

Step 2: Compounding the Paste

The process uses a specific "paste grade" of PTFE resin, which has fine particles suited for this technique. This powder is carefully blended with a lubricant, typically a mineral spirit or naphtha, and often with specialized fillers to enhance specific properties like conductivity or wear resistance.

The lubricant is essential; it allows the PTFE particles to slide past each other without clumping during the next stages.

Step 3: Preforming and Extrusion

The lubricated paste is compressed under low pressure into a cylindrical billet or "preform." This preform is then forced through a die in an extruder.

This step shapes the material into a basic form, like a sheet or tube, and begins to align the PTFE particles.

Step 4: Fibrillation via Mechanical Stress

This is the most critical step in creating the structure. The extruded material is subjected to intense mechanical stress through calendering (rolling between high-pressure rollers) and/or stretching in one or more directions.

This physical force does not break the material. Instead, it causes the individual PTFE particles to shear and deform into a network of interconnected fibers, a process known as fibrillation. This is what creates the material's signature porous, web-like internal structure.

Step 5: Sintering to Finalize the Product

Finally, the fibrillated material is heated in a controlled oven. The first phase of heating evaporates the lubricant.

The temperature is then raised above the melting point of PTFE (around 327°C or 621°F). This process, called sintering, fuses the nodes of the fibrous network together, locking the porous microstructure into a permanent and stable form.

Why This Process Matters: The Resulting Properties

Understanding the manufacturing process is key to understanding why structured PTFE is chosen for demanding applications. The steps are not arbitrary; each one directly contributes to the material's unique high-performance characteristics.

The Creation of Porosity

The stretching and fibrillation process creates billions of microscopic pores per square inch. This makes the material microporous, allowing vapor to pass through while blocking liquid. This is the principle behind breathable, waterproof fabrics.

The Strength of the Fibrous Network

The web of interconnected fibers gives structured PTFE an exceptionally high strength-to-weight ratio. The material is strong and durable yet remains lightweight and flexible.

Tailored Material Performance

The ability to add fillers during the initial compounding stage allows for precise customization. This transforms PTFE from a simple plastic into an engineered material platform for gaskets, seals, dielectric insulators, and more.

Connecting Manufacturing to Material Selection

Choosing the right material requires understanding how it was made. The manufacturing steps for structured PTFE directly correlate to its final performance capabilities.

- If your primary focus is porosity and fluid transfer: The controlled stretching and calendering steps are what determine the final pore size and flow characteristics.

- If your primary focus is high tensile strength and flexibility: The degree of fibrillation, created by the extrusion and mechanical working of the paste, is the most critical factor.

- If your primary focus is specialized thermal or electrical properties: The initial compounding stage, where specific fillers are blended with the PTFE resin, dictates these advanced capabilities.

This deliberate, multi-stage process is how a basic polymer is transformed into a versatile, high-performance structured material.

Summary Table:

| Manufacturing Step | Key Action | Purpose/Outcome |

|---|---|---|

| Compounding | Mix PTFE powder with lubricant & fillers | Creates a workable paste; allows for property customization |

| Extrusion | Force paste through a die | Shapes material and begins particle alignment |

| Fibrillation | Stretch/roll material (calendering) | Creates the fibrous network and porous structure |

| Sintering | Heat above PTFE melting point | Fuses the structure, locking in properties permanently |

Need custom PTFE components with specific performance characteristics?

The unique properties of structured PTFE—like controlled porosity, high tensile strength, and tailored electrical or thermal performance—are a direct result of its specialized manufacturing process. At KINTEK, we leverage this precise engineering to manufacture high-quality PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders. Let us help you solve your most challenging application requirements.

Contact our experts today to discuss your project needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- In what types of environments are PTFE envelope gaskets effective? Superior Sealing for Corrosive & Delicate Flange Systems

- How is Teflon used in the aerospace industry? Essential for Seals, Coatings & Insulation

- What are the electrical applications of PTFE sheets? Unlock Superior Insulation for Demanding Electronics

- Why are PTFE bearings preferred in chemical processing equipment? Unmatched Chemical Inertness for Reliability

- What are the different operation mechanisms for PTFE butterfly valves? Choose the Right Operator for Your System

- What are the potential issues of not using a Teflon sheet with a heat press? Protect Your Equipment & Projects

- What are the operating temperature ranges for PTFE and nylon? Choose the Right Polymer for Extreme or Moderate Heat

- How does PCTFE compare to PTFE for cryogenic applications? Choose the Right Material for Extreme Cold