In the semiconductor industry, Polytetrafluoroethylene (PTFE) is a critical material used for components that must withstand extremely harsh chemical environments and wide temperature ranges without contaminating the manufacturing process. Due to its unique properties, it is specified in ultra-pure grades for applications like custom labware, fluid handling systems, and protective encapsulations for heating elements.

The core reason PTFE is indispensable in chip fabrication is its near-total chemical inertness combined with high thermal stability. These properties ensure that it will not react with or leach impurities into the aggressive chemicals and ultra-pure water used, which would otherwise ruin the microscopic circuitry on a silicon wafer.

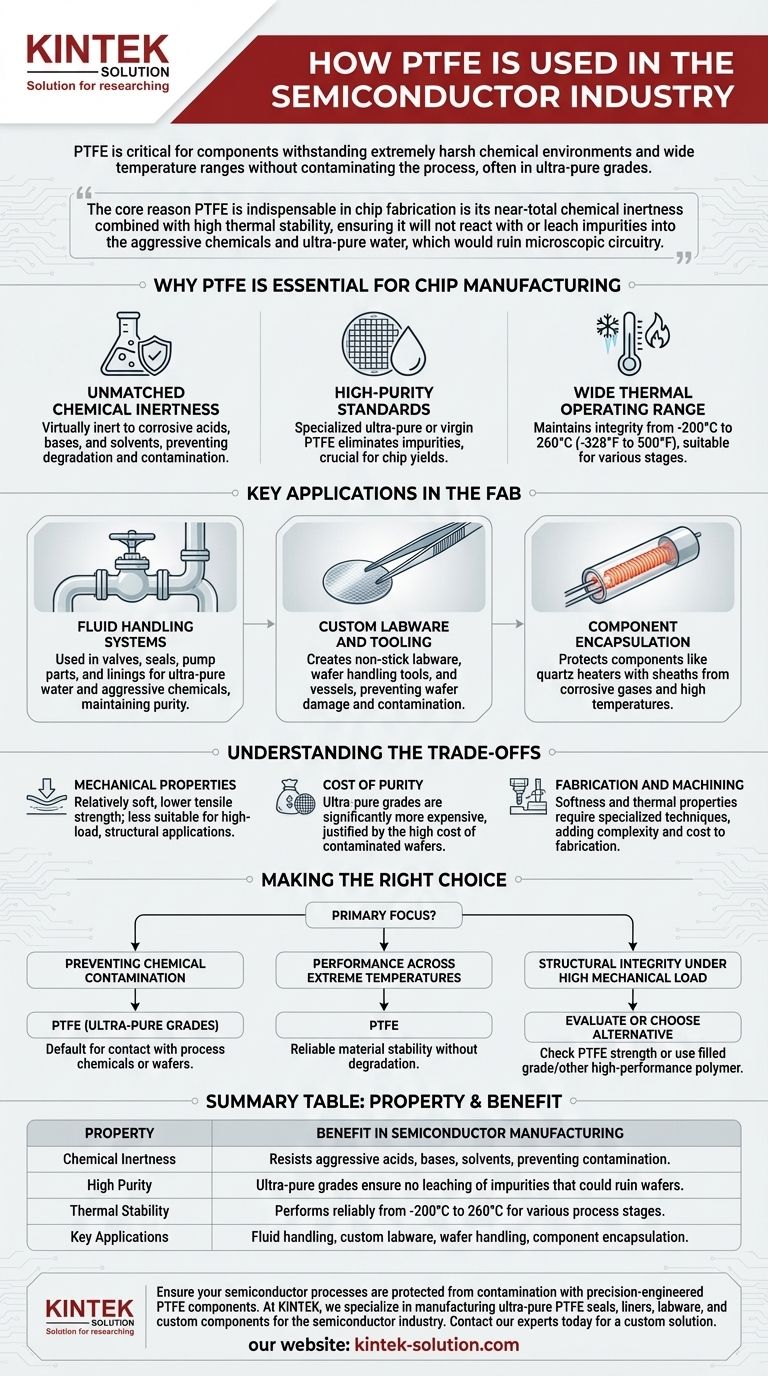

Why PTFE is Essential for Chip Manufacturing

The environment inside a semiconductor fabrication plant, or "fab," is one of the most demanding on Earth. Materials must perform flawlessly under extreme conditions where even microscopic contamination can lead to catastrophic failure. PTFE's unique molecular structure makes it one of the few materials that can meet these demands.

Unmatched Chemical Inertness

Semiconductor manufacturing relies on a sequence of steps involving highly corrosive and reactive chemicals, including strong acids, bases, and solvents.

PTFE is virtually inert, meaning it does not react with these aggressive substances. This prevents the material from degrading and, more importantly, ensures it does not introduce contaminants into the process fluids.

High-Purity Standards

Standard-grade polymers are not suitable for semiconductor applications because they can contain fillers, processing aids, or other impurities that can leach out.

For this industry, specialized ultra-pure or virgin PTFE is used. This grade is manufactured to the highest purity standards to eliminate any risk of contamination that could affect chip yields.

Wide Thermal Operating Range

Chip fabrication involves processes that span a vast temperature spectrum, from cryogenic temperatures to several hundred degrees Celsius.

PTFE maintains its integrity and stability across an exceptionally broad range, typically from -200°C to 260°C (-328°F to 500°F), making it suitable for components used in various heating and cooling stages.

Key Applications in the Fab

PTFE's properties translate directly into specific, high-value applications throughout the semiconductor manufacturing process, particularly where purity and chemical resistance are paramount.

Fluid Handling Systems

The transport of ultra-pure water (UPW) and aggressive process chemicals is a critical function in a fab.

PTFE is used extensively for valves, seals, pump parts, and linings for hoses and pipes. Its non-reactive surface ensures the purity of the fluid it is transporting is maintained from the source to the point of use.

Custom Labware and Tooling

Any tool that comes into direct or indirect contact with a silicon wafer is a potential source of contamination.

Because of its purity and non-stick properties, PTFE is used to create custom labware, wafer handling tools (like tweezers and grips), and process vessels. This ensures that wafers are not damaged or contaminated during handling and processing.

Component Encapsulation

Many components within process chambers must be protected from the harsh chemical environment.

PTFE is used for encapsulation devices, such as protective sheaths for quartz heaters. The PTFE shield protects the heater from corrosive gases while withstanding the high operating temperatures.

Understanding the Trade-offs

While its properties make it ideal for many applications, PTFE is not a universal solution. Understanding its limitations is key to proper material selection.

Mechanical Properties

Compared to metals or other engineered polymers, PTFE is a relatively soft material with lower tensile strength and resistance to creep (deformation under constant load).

This makes it less suitable for high-load, structural applications where mechanical rigidity is the primary requirement.

Cost of Purity

The ultra-pure grades of PTFE required by the semiconductor industry are significantly more expensive than standard industrial grades.

This cost is justified by the immense expense of a single contaminated batch of wafers, making the investment in high-purity materials a necessary form of insurance.

Fabrication and Machining

While PTFE can be machined into complex shapes, its softness and thermal properties require specialized techniques to hold tight tolerances. This can add complexity and cost to the fabrication of custom parts.

Making the Right Choice for Your Process

Selecting the correct material is fundamental to ensuring process stability, maximizing yield, and avoiding costly downtime in semiconductor manufacturing.

- If your primary focus is preventing chemical contamination: PTFE's inertness and availability in ultra-pure grades make it the default choice for any surface in direct contact with process chemicals or wafers.

- If your primary focus is performance across extreme temperatures: For components exposed to the wide thermal cycles common in fabrication, PTFE provides reliable material stability without degradation.

- If your primary focus is structural integrity under high mechanical load: Carefully evaluate if PTFE's strength is sufficient, or if a filled grade of PTFE or a different high-performance polymer is necessary.

Ultimately, leveraging PTFE correctly is a foundational element of maintaining the pristine conditions required for modern chip fabrication.

Summary Table:

| Property | Benefit in Semiconductor Manufacturing |

|---|---|

| Chemical Inertness | Resists aggressive acids, bases, and solvents, preventing contamination. |

| High Purity | Ultra-pure grades ensure no leaching of impurities that could ruin wafers. |

| Thermal Stability | Performs reliably from -200°C to 260°C, suitable for various process stages. |

| Key Applications | Fluid handling systems, custom labware, wafer handling tools, and component encapsulation. |

Ensure your semiconductor processes are protected from contamination with precision-engineered PTFE components.

At KINTEK, we specialize in manufacturing ultra-pure PTFE seals, liners, labware, and custom components for the semiconductor, medical, and laboratory industries. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you receive components that meet the strictest purity and performance standards, safeguarding your yields and process integrity.

Contact our experts today to discuss your specific PTFE requirements and get a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does bearing pressure affect the coefficient of friction in PTFE slide bearings? Maximize Performance with Higher Loads

- What medical applications benefit from extruded PTFE rods? Precision Components for Surgical & Diagnostic Devices

- How do PTFE seals compare to traditional sealing materials in terms of service life? Extend Equipment Lifespan Dramatically

- What role does temperature stability play in PTFE coated fasteners? Ensuring Reliability in Extreme Environments

- What is the thermal shock resistance of PTFE lined pipes? Engineered for Extreme Temperature Cycling

- What are the advantages of using PTFE combined with glass fiber aggregates? Achieve Superior Strength & Durability

- How have PTFE coatings transformed the food processing industry? Boosting Efficiency, Safety & Profitability

- How does PTFE's pressure resistance compare to other materials? Unmatched Performance for Demanding Systems