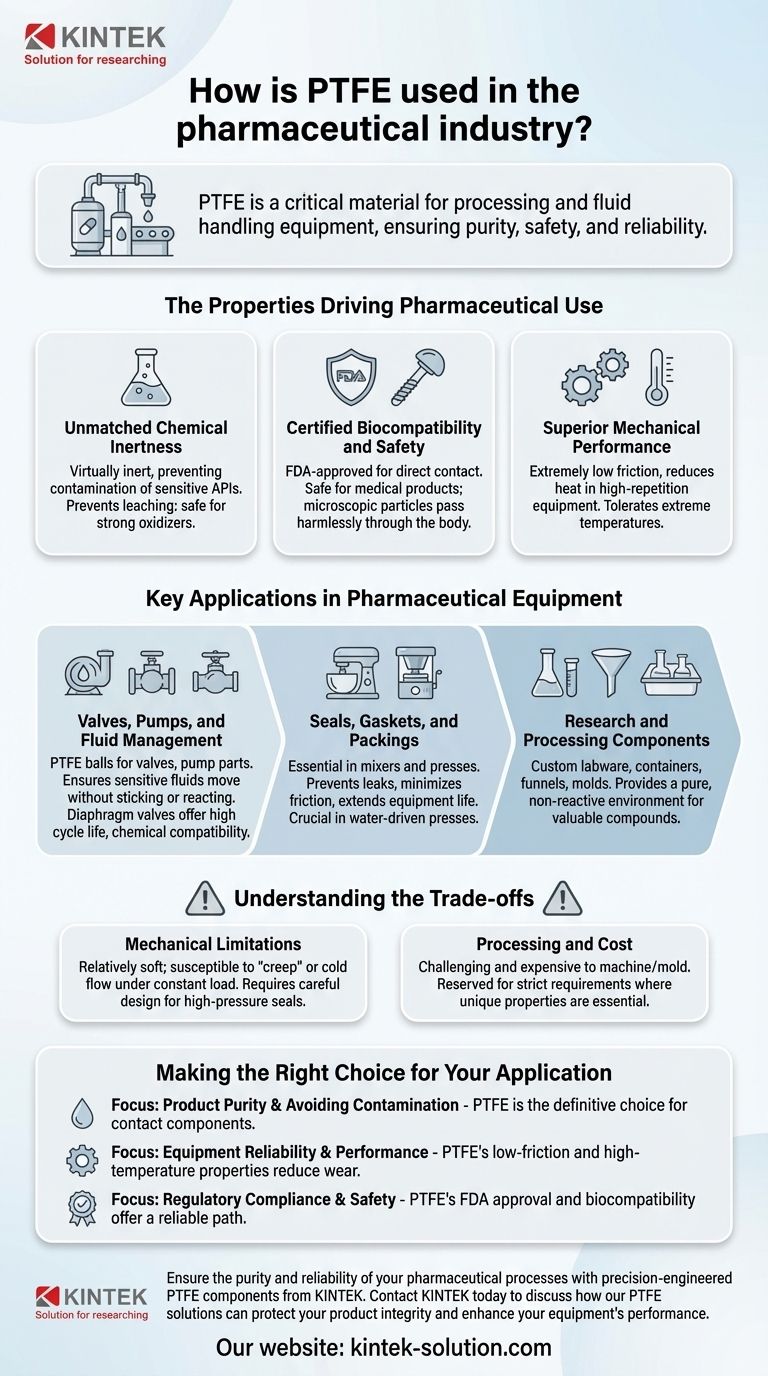

In the pharmaceutical industry, Polytetrafluoroethylene (PTFE) is a critical material used for components within processing and fluid handling equipment. Its unique combination of chemical inertness, biocompatibility, and low friction makes it essential for manufacturing pure and safe medical products in equipment like mixers, presses, valves, and pumps.

The core reason PTFE is indispensable in pharmaceuticals is its ability to protect product purity. Its non-reactive and non-stick surface ensures that sensitive chemical compounds are not contaminated during manufacturing, while its mechanical properties enhance the reliability of the equipment itself.

The Properties Driving Pharmaceutical Use

The selection of any material in a regulated environment like pharmaceuticals is a deliberate choice. PTFE is chosen because its fundamental characteristics directly solve the industry's primary challenges: purity, safety, and reliability.

Unmatched Chemical Inertness

PTFE is virtually inert, meaning it does not react with the vast majority of chemicals. This is critical when producing sensitive and complex active pharmaceutical ingredients (APIs).

This non-reactivity prevents leaching or contamination, ensuring the final drug's composition and purity remain exactly as intended. It's why PTFE is trusted for handling even strong oxidizers.

Certified Biocompatibility and Safety

The material is FDA-approved for use in pharmaceutical applications. Its biocompatibility means it is safe for direct contact with medical products and even for use in medical implants.

Should a microscopic particle from a seal or bushing wear off, it is designed to pass through the human body without causing harm or reaction, a crucial safety consideration.

Superior Mechanical Performance

PTFE has an extremely low coefficient of friction. This "slipperiness" is vital in high-repetition equipment like tablet presses, where it reduces heat buildup and prevents damage to both the seal and the product.

It also tolerates extreme temperatures, allowing it to maintain its integrity and performance during various manufacturing stages without degrading or compromising the process.

Key Applications in Pharmaceutical Equipment

PTFE is not a single-use material; its versatility allows it to be engineered into various components, each serving a specific function in the drug manufacturing lifecycle.

Valves, Pumps, and Fluid Management

PTFE is commonly formed into balls for valves and parts for pumps. In these roles, it ensures that sensitive fluids move through the system without sticking to surfaces or reacting with components.

Diaphragm valves made from PTFE are particularly valued for their high cycle life, chemical compatibility, and low surface adhesion, making them durable and cost-effective solutions.

Seals, Gaskets, and Packings

In machinery such as mixers and presses, PTFE seals and packings are essential. They prevent leaks while minimizing friction, which extends the life of the equipment and protects the integrity of the product.

This is especially important in water-driven presses, where any leakage must not spoil the batch.

Research and Processing Components

Beyond large machinery, PTFE is used to create custom labware, containers, funnels, and molds. In both research and production, these components provide a pure, non-reactive environment for handling valuable compounds.

Understanding the Trade-offs

While PTFE's benefits are clear, it's important to understand its limitations to ensure it is applied correctly. No material is perfect for every situation.

Mechanical Limitations

PTFE is a relatively soft material and can be susceptible to "creep" or cold flow, where it deforms over time under a constant load. This must be accounted for in the design of high-pressure seals and structural components.

Processing and Cost

PTFE can be more challenging and expensive to machine and mold than other polymers. Its use is therefore typically reserved for applications where its unique properties are a strict requirement, not just a preference.

Making the Right Choice for Your Application

Selecting the correct material is fundamental to successful pharmaceutical manufacturing. PTFE offers a powerful solution, but its application should align with your primary goal.

- If your primary focus is absolute product purity and avoiding contamination: PTFE is the definitive choice for any component that makes direct contact with active ingredients or the final product.

- If your primary focus is equipment reliability and performance: PTFE's low-friction and high-temperature properties are ideal for reducing wear in high-cycle machinery like presses, pumps, and mixers.

- If your primary focus is regulatory compliance and safety: PTFE's established FDA approval and proven biocompatibility offer a straightforward and reliable path for process validation.

Ultimately, PTFE serves as a cornerstone material that enables the safe, pure, and efficient production of modern medicines.

Summary Table:

| Property | Benefit in Pharma | Key Application |

|---|---|---|

| Chemical Inertness | Prevents contamination of APIs | Valves, Pumps, Fluid Handling |

| Biocompatibility (FDA-Approved) | Ensures patient safety | Seals, Gaskets, Labware |

| Low Coefficient of Friction | Reduces wear in high-cycle equipment | Tablet Presses, Mixers |

| High-Temperature Tolerance | Maintains integrity during processing | Custom Components, Liners |

Ensure the purity and reliability of your pharmaceutical processes with precision-engineered PTFE components from KINTEK.

We specialize in manufacturing high-quality PTFE seals, liners, valves, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components that meet the stringent demands of pharmaceutical manufacturing.

Contact KINTEK today to discuss how our PTFE solutions can protect your product integrity and enhance your equipment's performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does the cost of PTFE bushes compare to traditional bushings? Analyze the True Long-Term Value

- What is a PTFE lined butterfly valve? A Guide to Corrosion-Resistant Flow Control

- What are the primary applications of PTFE bars in the chemical industry? Solve Your Toughest Corrosion Problems

- What are the key features of fully lined ball valves? Engineered for Total Corrosion Resistance

- In which industries are spring-energized PTFE seals commonly used? Critical Applications for Extreme Conditions

- How is PTFE used in the automotive industry? Enhancing Vehicle Reliability and Performance

- What are the key dielectric properties of PTFE that make it suitable for wires and cables? Ensuring Signal Integrity in Extreme Conditions

- How does the low coefficient of friction in PTFE bushes benefit industrial applications? Reduce Wear & Maintenance