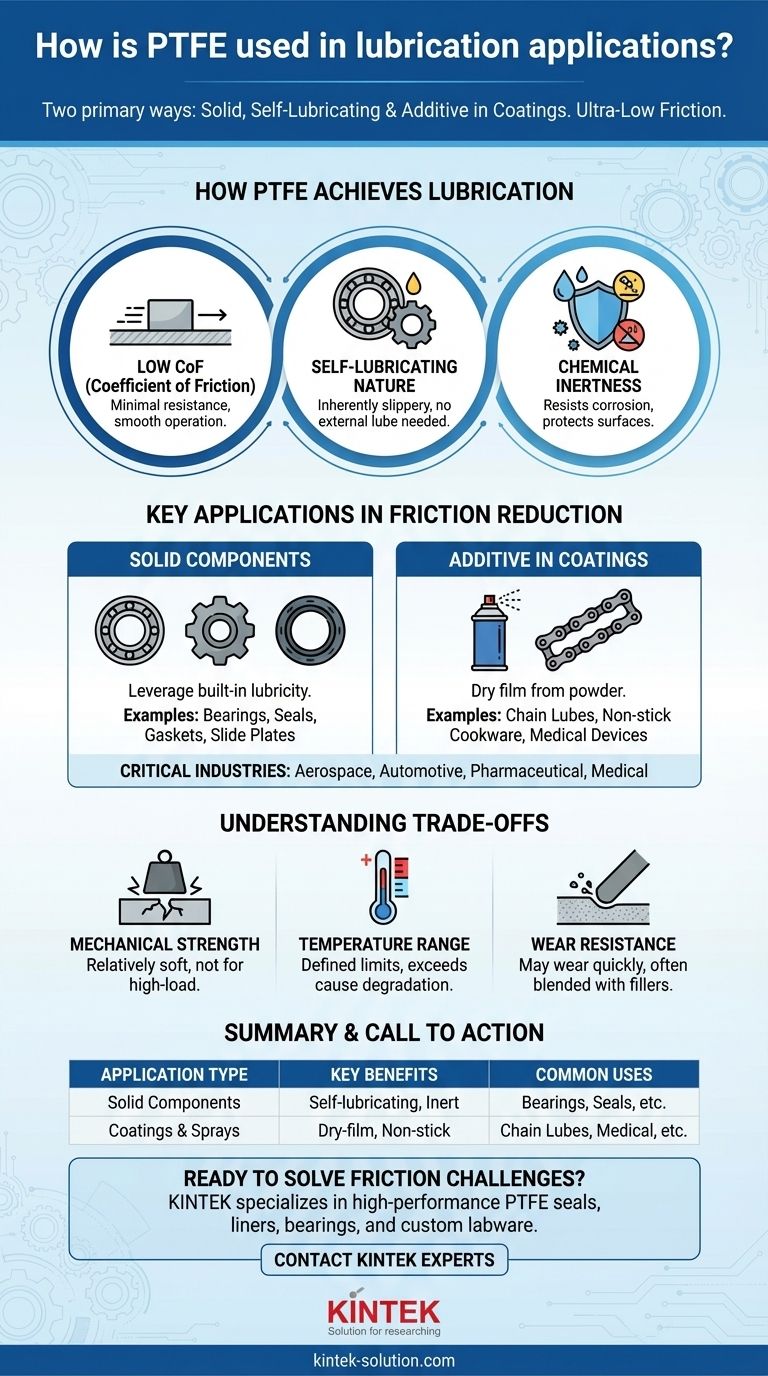

In lubrication applications, Polytetrafluoroethylene (PTFE) is used in two primary ways: as a solid, self-lubricating material for mechanical components, and as an additive in coatings and sprays to create an ultra-low-friction surface. Its effectiveness stems from having one of the lowest coefficients of friction of any known solid material, which allows it to dramatically reduce wear, energy consumption, and the need for traditional liquid lubricants.

The core function of PTFE in lubrication is to create a non-stick, low-friction interface between moving parts. This can be achieved either by constructing the part itself from solid PTFE or by applying a PTFE-based coating to an existing surface.

How PTFE Achieves Its Lubricating Properties

PTFE's unique molecular structure is the source of its remarkable lubricating capabilities. This structure gives rise to properties that are highly desirable in friction-reduction applications.

Exceptionally Low Coefficient of Friction

The primary reason PTFE is an excellent lubricant is its extremely low coefficient of friction. This means surfaces can slide against it with minimal resistance.

This property allows it to outperform materials like nylon and acetal in sliding-action parts, leading to smoother and more efficient operation.

The Self-Lubricating Nature

When used as a solid material for components like bearings or slide plates, PTFE is inherently self-lubricating.

It does not require external oils or greases to maintain low-friction movement. This simplifies machinery design and drastically reduces maintenance requirements.

Chemical Inertness and Stability

PTFE is highly non-reactive and resists corrosion. When used as a lubricant or coating, such as on a bicycle chain, it provides a protective barrier against moisture and other corrosive elements.

This inertness also makes it ideal for use in sensitive environments like food processing and medical applications, where lubricant purity is critical.

Key Applications in Friction Reduction

PTFE's versatility allows it to be deployed across a vast range of industries, from consumer goods to advanced aerospace technology.

Solid, Self-Lubricating Components

Many mechanical parts are fabricated directly from PTFE to leverage its built-in lubricity.

Common examples include plain bearings, gears, seals, gaskets, and slide plates. These components ensure leak-proof and low-friction operation without the mess or maintenance of traditional lubricants.

Additive in Sprays and Coatings

PTFE is frequently ground into a fine powder and added to liquid lubricants or spray-on coatings.

When applied, the carrier evaporates, leaving a dry film of PTFE on the surface. This is common in dry chain lubricants and non-stick cookware coatings, where it provides a clean, durable, low-friction surface.

Critical Industrial and Medical Equipment

In demanding environments, PTFE ensures reliability under extreme conditions. It is used in aerospace and automotive applications where consistent lubrication is non-negotiable.

In the pharmaceutical industry, its non-stick properties prevent material buildup on equipment like hoppers. In medical devices, PTFE is used to coat catheters, inhibiting bacterial growth and ensuring smooth insertion.

Understanding the Trade-offs

While its lubricating properties are exceptional, PTFE is not a universal solution. Understanding its limitations is key to applying it correctly.

Mechanical Strength

Solid PTFE is a relatively soft material. While this is advantageous for applications like seals and gaskets that need to conform to a surface, it lacks the structural strength for high-load, high-pressure mechanical parts.

Temperature Range

PTFE has a well-defined operational temperature range. Exceeding this can cause the material to degrade, compromising its structural and lubricating properties.

Wear Resistance

In high-wear scenarios, pure PTFE may abrade more quickly than harder materials. For this reason, it is often blended with fillers like glass, carbon, or graphite to enhance its durability and wear resistance.

How to Apply This to Your Goal

Your specific objective will determine the best way to leverage PTFE's properties.

- If your primary focus is creating self-lubricating parts: Use solid PTFE for components like bearings, washers, or slide plates to eliminate the need for external lubricants entirely.

- If your primary focus is reducing friction on existing surfaces: Apply a PTFE-based dry film lubricant or spray to create a durable, clean, and low-friction coating.

- If your primary focus is operational purity and cleanliness: Choose PTFE for components in food, medical, or pharmaceutical equipment to prevent contamination and material buildup.

Ultimately, PTFE provides a powerful and versatile solution for managing friction across a wide spectrum of engineering challenges.

Summary Table:

| Application Type | Key Benefits | Common Uses |

|---|---|---|

| Solid Components | Self-lubricating, chemical inertness, leak-proof | Bearings, seals, gaskets, slide plates |

| Coatings & Sprays | Dry-film, non-stick, clean operation | Chain lubricants, non-stick surfaces, medical devices |

| Critical Industries | High purity, reliability in extreme conditions | Aerospace, automotive, pharmaceutical, medical |

Ready to solve your toughest friction challenges with precision PTFE components?

KINTEK specializes in manufacturing high-performance PTFE seals, liners, bearings, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our custom fabrication expertise ensures you get the exact self-lubricating solution your application demands.

Contact our PTFE experts today to discuss how we can enhance your equipment's efficiency and reduce maintenance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability