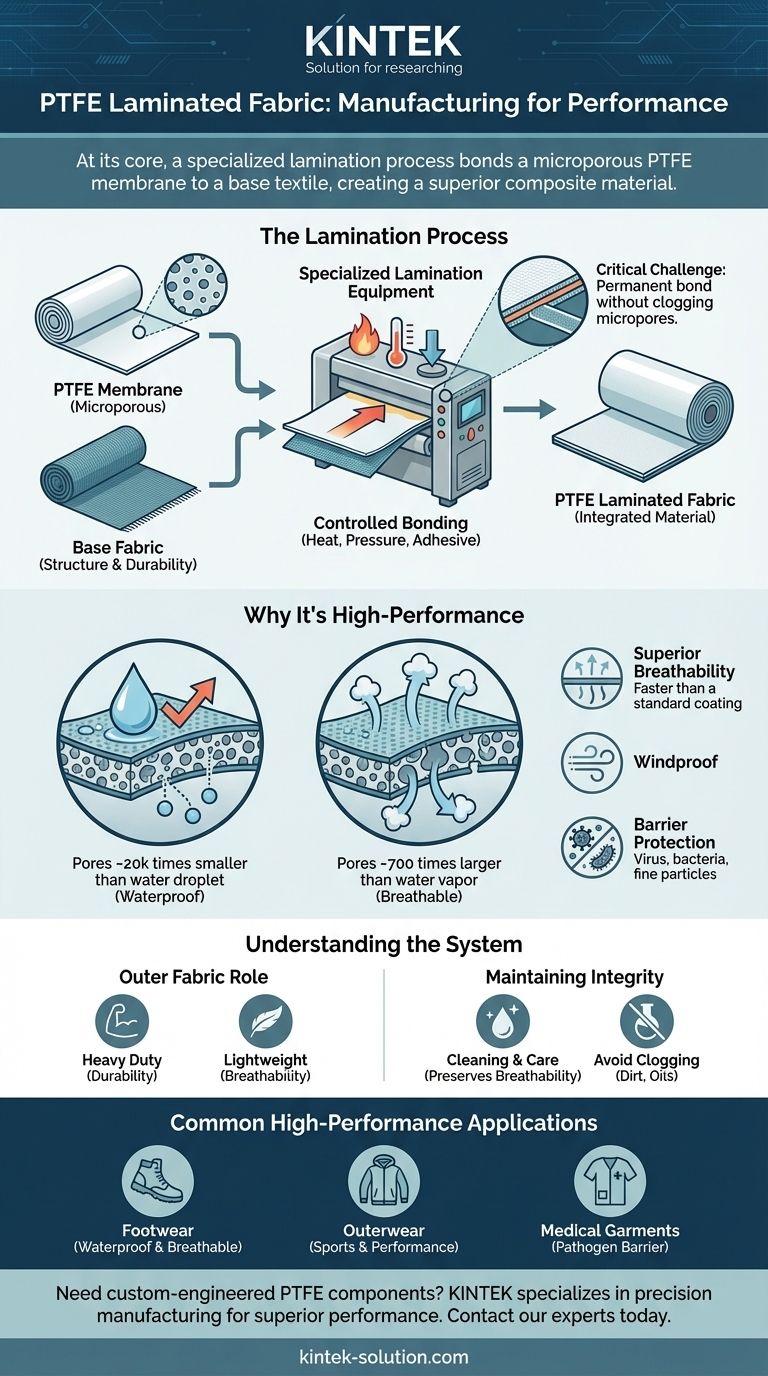

At its core, PTFE laminated fabric is created through a specialized lamination process that bonds a microporous Polytetrafluoroethylene (PTFE) membrane to a base textile. This advanced technique combines the properties of a standard fabric, such as nylon or leather, with the high-performance characteristics of the PTFE membrane. The result is a composite material engineered for superior protection and comfort.

The essential goal of the manufacturing process is not simply to glue two layers together. It is to create a durable, waterproof, and windproof material that critically maintains the microscopic pores of the PTFE membrane, allowing it to remain exceptionally breathable.

The Lamination Process Explained

The creation of PTFE laminated fabric is a precise engineering task focused on uniting two dissimilar materials without compromising the unique benefits of either one.

The Core Components

The process begins with two distinct layers: a base fabric and the PTFE membrane.

The PTFE membrane is the functional heart of the material. It is an incredibly thin polymer sheet stretched to create billions of microscopic pores per square inch.

The base fabric provides the structure, durability, and desired appearance. This can be anything from rugged leather for boots to lightweight woven textiles for performance apparel.

The Bonding Method

Using specialized equipment, the fragile PTFE membrane is carefully bonded to the more robust base fabric. This process typically involves a specific adhesive and the controlled application of heat and pressure.

The critical challenge is to achieve a permanent bond across the entire surface without clogging the membrane's micropores. A successful lamination ensures the final fabric is a single, integrated material.

The Source of Its High-Performance Qualities

The unique properties of this fabric stem directly from the engineered structure of the PTFE membrane, which is preserved during lamination.

The Microporous Structure

The pores in the PTFE membrane are the key. They are approximately 20,000 times smaller than a water droplet, making it impossible for rain or liquid to penetrate from the outside.

Simultaneously, these same pores are about 700 times larger than a water vapor molecule. This allows perspiration from the body to escape easily, creating exceptional breathability.

Superior Breathability

This structure gives PTFE laminates a significant advantage over conventional coatings. They can be eight to ten times more breathable than standard coated waterproof fabrics.

This high rate of moisture vapor transmission is what prevents the clammy, damp feeling common with lesser waterproof materials during physical activity.

A Barrier Against More Than Water

The tightly controlled pore size also makes the membrane an effective physical barrier to other elements.

This includes providing resistance to blood penetration, blocking viruses and bacteria, and preventing fine particles from passing through, with barrier rates often exceeding 90%.

Understanding the Trade-offs and Applications

While highly effective, the performance of a PTFE laminate is not absolute. It depends on the complete system and proper care.

The Role of the Outer Fabric

The choice of base textile is critical. A heavy leather laminated with PTFE will offer excellent durability for a boot but will have different breathability characteristics than a lightweight nylon laminate designed for a running jacket.

The outer fabric is also the first line of defense and its performance directly impacts the membrane.

Maintaining Micropore Integrity

The microscopic pores that provide breathability can become clogged over time by dirt, oils, and detergents.

Proper cleaning and care are essential to maintain the fabric's performance, ensuring the pathways for moisture vapor remain open and effective.

Common High-Performance Applications

Given its unique balance of protection and comfort, PTFE laminated fabric is a primary choice for demanding environments.

It is used extensively in waterproof and breathable footwear, high-performance outerwear for outdoor sports, and protective medical garments where a barrier against pathogens is crucial.

Making the Right Choice for Your Application

Selecting the correct laminate requires matching the material's construction to your primary goal.

- If your primary focus is maximum weather protection and durability: Choose a laminate built on a robust and heavy-duty base fabric, such as thick nylon or leather.

- If your primary focus is lightweight comfort and breathability: Opt for a laminate that uses a lighter, more flexible base textile to maximize moisture vapor transfer.

- If your primary focus is specialized barrier protection: Ensure the specific laminate is certified for its resistance to blood, viruses, or the specific particles relevant to your medical or industrial use case.

Ultimately, understanding the lamination process empowers you to select a material precisely engineered to meet your specific performance demands.

Summary Table:

| Key Manufacturing Step | Purpose | Key Outcome |

|---|---|---|

| PTFE Membrane Creation | Stretch PTFE to create billions of microscopic pores. | Provides the core waterproof & breathable functionality. |

| Lamination Bonding | Use heat, pressure, and adhesive to bond membrane to base fabric. | Creates a single, durable composite without clogging pores. |

| Base Fabric Selection | Choose a textile (e.g., nylon, leather) for structure and durability. | Determines the final product's weight, flexibility, and application. |

Need custom-engineered PTFE components for your application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE solutions. Whether you require custom seals, liners, labware, or specialized fabrications for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures superior material performance and durability.

We handle everything from prototypes to high-volume orders, guaranteeing a perfect fit for your demanding requirements.

Contact our experts today to discuss how our PTFE components can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability