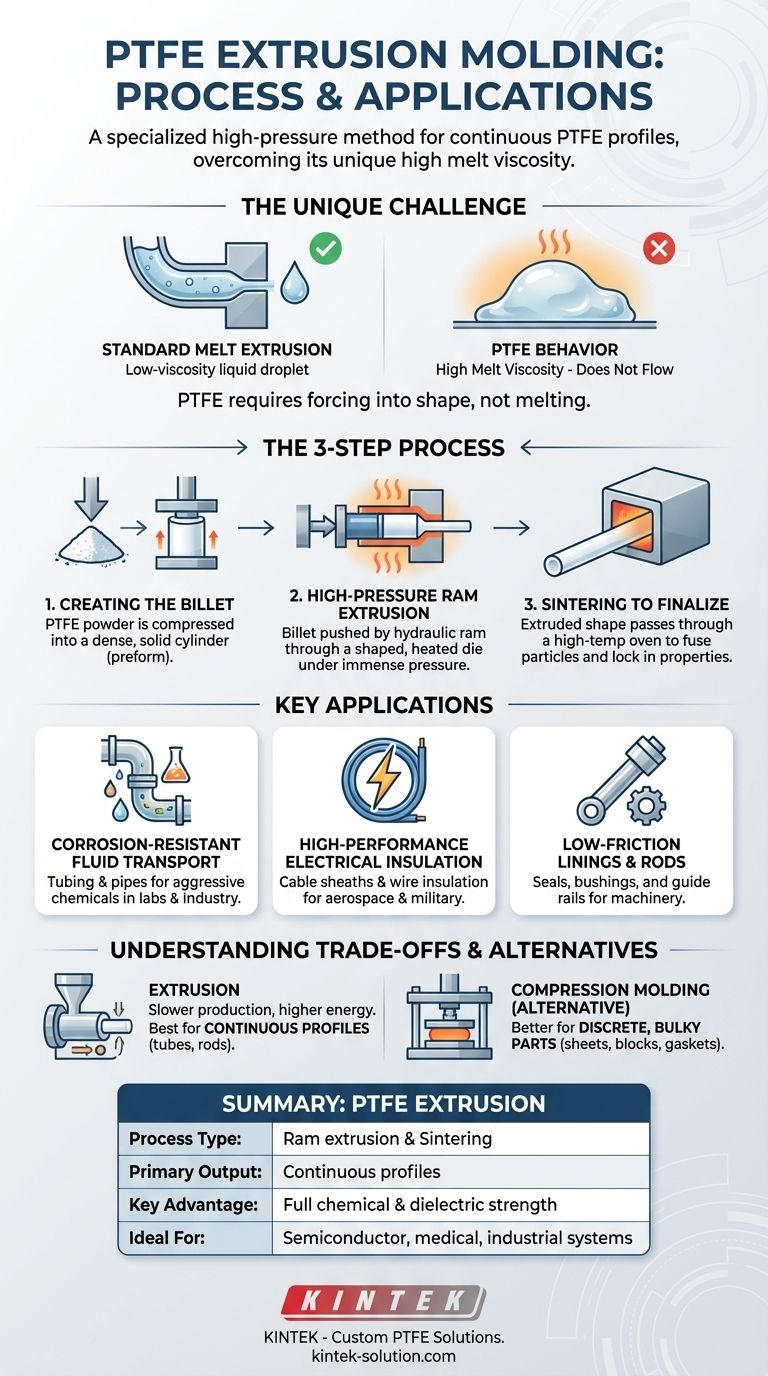

At its core, PTFE extrusion molding is a specialized, multi-stage manufacturing process designed to overcome the unique challenges of Polytetrafluoroethylene. It involves compressing PTFE powder into a solid billet, forcing this billet through a shaped die under immense pressure, and then sintering (heating) the resulting form to fuse the particles and achieve the material's final properties. This method is the definitive solution for creating continuous, long-length products that leverage PTFE's exceptional characteristics.

The central challenge with PTFE is its extremely high melt viscosity; it doesn't truly melt and flow like other plastics. Therefore, PTFE extrusion is not a melt process but a high-pressure consolidation and sintering method designed to form continuous profiles from a gel-like material.

The Unique Challenge of Processing PTFE

Polytetrafluoroethylene (PTFE) is renowned for its chemical inertness, thermal stability, and low-friction surface. However, these same properties make it exceptionally difficult to process using conventional plastic manufacturing techniques.

Why Standard Melt Extrusion Fails

Most common plastics, like polyethylene or PVC, can be melted into a low-viscosity liquid and easily pushed through a die.

PTFE behaves differently. When heated past its melting point of approximately 327°C, it does not become a free-flowing liquid. Instead, it transitions into a translucent, high-viscosity gel that cannot be processed by standard screw extruders.

The Necessity of a Specialized Approach

Because PTFE won't flow, it must be forced into shape. The extrusion process for PTFE is more analogous to compacting a powder and pushing a solid plug through an opening, followed by a heat treatment to create a solid, unified part.

The PTFE Extrusion Process: A Step-by-Step Breakdown

The method is a precise, multi-step operation designed to produce uniform, continuous profiles like tubing, rods, or wire insulation.

Step 1: Creating the Billet

The process begins with fine PTFE powder. This powder is carefully loaded into a cylindrical mold and compressed under high pressure to form a dense, solid cylinder known as a billet or "preform."

This initial compression creates a fragile but handleable shape that is ready for the next stage.

Step 2: High-Pressure Ram Extrusion

The pre-formed billet is placed into the extruder. A hydraulic ram then pushes the billet under extremely high pressure, forcing the material through a heated die.

The die gives the extrudate its final shape, such as a tube or rod. This step is performed slowly and under precise temperature control to ensure a consistent profile.

Step 3: Sintering to Finalize Properties

The extruded shape that emerges from the die is not yet finished. It is immediately passed through a long, high-temperature oven for a process called sintering.

During sintering, the individual PTFE particles fuse together, creating a solid, non-porous material and locking in its final dimensions and superior mechanical properties.

Key Applications Driven by Extrusion

PTFE extrusion is the go-to method for creating long, continuous parts where the material's unique properties are critical.

Corrosion-Resistant Fluid Transport

The process is ideal for manufacturing long lengths of tubing and thin-walled pipes. Because PTFE is chemically inert, these tubes are essential for safely transporting aggressive chemicals in laboratories and industrial processing plants.

High-Performance Electrical Insulation

PTFE's excellent dielectric properties and high-temperature resistance make it a premier material for electrical insulation. Extrusion is used to create cable sheaths and wire insulation for demanding aerospace, military, and industrial applications.

Low-Friction Linings and Rods

Continuous rods and lining profiles are extruded for use in applications requiring low friction and high durability, such as high-performance seals, bushings, and guide rails in machinery.

Understanding the Trade-offs

While highly effective, PTFE extrusion is a more complex and resource-intensive process than standard thermoplastic extrusion.

Slower Production Speeds

The need to create individual billets and the slow, high-pressure nature of ram extrusion result in significantly lower output rates compared to melt-processing common plastics. This makes it a process reserved for high-value applications.

Higher Energy Consumption

The multiple high-temperature sintering stages are energy-intensive, contributing to the higher cost of PTFE components.

An Alternative: Compression Molding

For parts that are not long and continuous, such as thick sheets, large blocks, or complex gaskets, an alternative method called compression molding is used. This involves pressing PTFE powder directly into a final-shaped mold and sintering it, which is better suited for discrete, bulky components.

Making the Right Choice for Your Application

Selecting the correct manufacturing process is critical to leveraging PTFE's full potential.

- If your primary focus is continuous-length products: PTFE extrusion is the only viable method for creating long tubes, rods, and wire insulation.

- If your primary focus is discrete, thick-walled components: Compression molding is the more efficient and appropriate choice for parts like sheets, blocks, and robust gaskets.

- If your application demands ultimate chemical and thermal resistance: Both processes deliver the full benefits of PTFE, with the component's geometry dictating the optimal method.

Ultimately, understanding that PTFE requires specialized handling is the key to successfully applying this remarkable high-performance material.

Summary Table:

| PTFE Extrusion Feature | Key Details |

|---|---|

| Process Type | Ram extrusion of powder billets, followed by sintering |

| Primary Output | Continuous-length profiles (tubes, rods, cable insulation) |

| Key Advantage | Creates parts with PTFE's full chemical inertness & dielectric strength |

| Ideal For | Semiconductor, medical, laboratory, and industrial fluid/electrical systems |

Need precision PTFE components for your critical application?

At KINTEK, we specialize in manufacturing high-quality PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, and industrial sectors. Our expertise in PTFE extrusion and compression molding ensures you get parts that meet exact specifications, from prototypes to high-volume production.

Contact us today to discuss how our custom PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do modern CNC machines contribute to energy efficiency in Teflon machining? Achieve Precision and Sustainability

- What are the common pitfalls in high-temperature and low-temperature scenarios for seals? Avoid Costly Seal Failures

- What are some common grades of PTFE used in fabrication? Choose the Right Material for Your Application

- What are the key properties of PTFE balls? Unmatched Performance for Extreme Industrial Environments

- How does thickness affect PTFE sheet selection? A Guide to Balancing Strength and Flexibility

- What is the function of PFA and PTFE lined check valves in chemical plants? Prevent Corrosive Backflow and Protect Equipment

- What are the main challenges when machining Teflon (PTFE)? Overcome Softness, Heat, and Precision Issues

- What are the tensile strengths of PTFE and graphite packing? Choosing the Right Material for Your Application