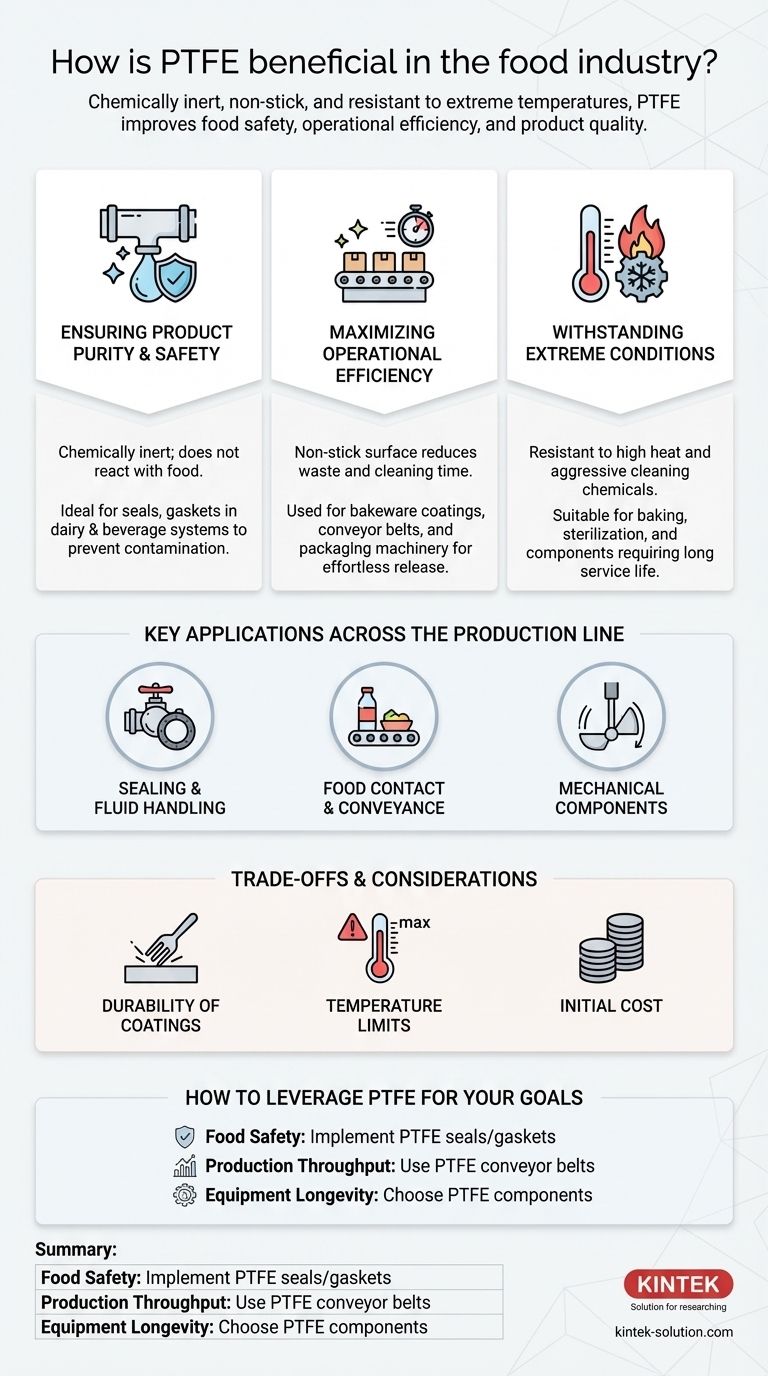

In the food industry, Polytetrafluoroethylene (PTFE) is highly beneficial due to its unique combination of properties: it is chemically inert, non-stick, and resistant to extreme temperatures. This makes it an invaluable material for improving food safety, enhancing operational efficiency, and ensuring product quality across a wide range of applications from baking to fluid processing.

The core value of PTFE in the food industry is its ability to create a clean, safe, and efficient production environment. By preventing contamination and minimizing downtime, it directly contributes to higher quality products and increased productivity.

The Pillars of PTFE's Value in Food Processing

The benefits of PTFE stem from three primary characteristics that are perfectly suited for the demands of handling consumable products. Each property solves a critical challenge faced by food and beverage manufacturers.

Ensuring Product Purity and Safety

PTFE is chemically inert, meaning it does not react with or leach into the substances it touches. This is paramount for food safety.

It is widely used for gaskets, seals, and packings, especially in the dairy and beverage industries, because it ensures the liquids flowing through the system remain uncontaminated. This prevents chemical degradation and maintains the integrity of the final product.

Maximizing Operational Efficiency

The most well-known property of PTFE is its non-stick surface. In food processing, this dramatically reduces product waste and cleaning time.

PTFE coatings on bakeware, conveyor belts, and packaging machinery ensure an effortless release of food products. This prevents sticky materials from adhering to equipment, which enhances production speed and maintains a higher standard of hygiene.

Withstanding Extreme Conditions

The food industry often involves high temperatures and aggressive cleaning chemicals. PTFE is exceptionally durable under these conditions.

Its resistance to a wide temperature range makes it suitable for baking and other high-heat processes. Furthermore, its ability to withstand acidic or alkaline foods and harsh cleaning agents means components made from PTFE last longer and require less maintenance.

Key Applications Across the Production Line

PTFE is not a single-use material; its versatility allows it to be integrated into nearly every stage of food production, from fluid handling to final packaging.

Sealing and Fluid Handling

In systems that transport liquids, preventing leaks and contamination is critical. PTFE valves, packings, and envelope gaskets provide a reliable seal.

Their chemical resistance is essential for handling corrosive fluids or ingredients, providing a cost-effective and low-maintenance solution that protects product quality.

Food Contact and Conveyance

For moving solid or semi-solid foods, maintaining momentum is key. PTFE-coated sheets and transport belts are standard in confectionery and baking.

The non-stick surface guarantees that products move smoothly through the line without sticking, breaking, or leaving residue behind, which in turn reduces waste.

Mechanical Components

PTFE can also serve as a high-performance mechanical component. It is used for non-metal bearings and in mixers where traditional lubricants are forbidden.

Because it has very low friction, it does not require grease, which could otherwise contaminate the food. This delivers a long service life while upholding strict hygiene standards.

Understanding the Trade-offs and Considerations

While highly beneficial, PTFE is not a universal solution. Acknowledging its limitations is key to using it effectively and responsibly.

Durability of Coatings

PTFE coatings, particularly on cookware or bakeware, can be susceptible to damage from sharp metal utensils or abrasive cleaning. Scratches can compromise the non-stick performance.

Temperature Limits

Although resistant to high heat, PTFE does have a maximum service temperature. Exceeding this limit can cause the material to degrade, making it crucial to operate within specified thermal ranges.

Initial Cost

Components made from high-quality, food-grade PTFE can have a higher upfront cost compared to traditional materials like rubber or certain plastics. However, this is often offset by longer life, reduced maintenance, and less downtime.

How to Leverage PTFE for Your Goals

The decision to use PTFE should align with your specific operational priorities.

- If your primary focus is food safety and hygiene: Implement PTFE seals, gaskets, and valves to ensure products are never contaminated by reactive or leaching materials.

- If your primary focus is production throughput: Use PTFE-coated conveyor belts and machinery parts to minimize cleaning time, reduce product waste, and prevent line stoppages.

- If your primary focus is equipment longevity: Choose PTFE components in environments with harsh chemicals or high temperatures to reduce maintenance cycles and replacement costs.

Ultimately, integrating PTFE into your operations is a strategic decision that enhances the safety, efficiency, and reliability of modern food production.

Summary Table:

| PTFE Property | Key Benefit in Food Industry | Common Applications |

|---|---|---|

| Chemically Inert | Ensures product purity, prevents contamination | Seals, gaskets, valves in dairy/beverage processing |

| Non-Stick Surface | Reduces waste, speeds up cleaning, improves hygiene | Conveyor belts, bakeware, packaging machinery |

| High-Temp Resistance | Withstands baking/sterilization, enhances equipment longevity | Components in ovens, mixers, fluid handling systems |

Ready to enhance your food production line with high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the food, beverage, and other specialized industries. Whether you need prototypes or high-volume orders, our custom fabrication ensures your equipment achieves maximum safety, efficiency, and longevity.

Contact us today to discuss how our PTFE solutions can meet your specific operational goals!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts