Expanded Polytetrafluoroethylene (ePTFE) is a specialized polymer created by transforming standard PTFE into a three-dimensional, web-like structure. This physical change produces billions of microscopic pores, giving the material a unique combination of properties that retain PTFE’s inherent chemical and thermal stability while adding new capabilities like breathability and soft conformability.

The core value of ePTFE comes from its unique structure. The expansion process creates a microscopic web of fibers and nodes, which allows the material to be porous and breathable while maintaining the exceptional chemical resistance and temperature stability of solid PTFE.

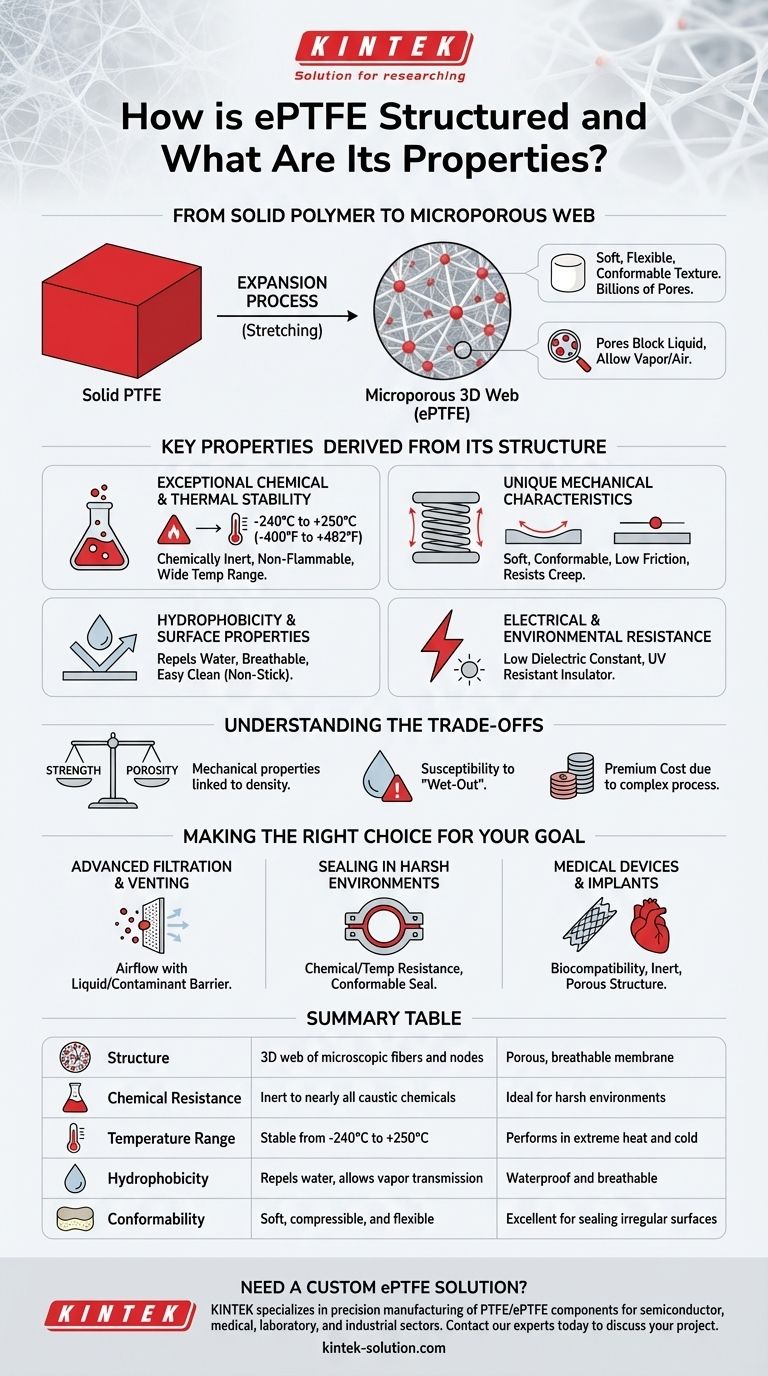

From Solid Polymer to Microporous Web

The defining characteristics of ePTFE are a direct result of the manufacturing process that turns a solid plastic into a porous membrane.

The Expansion Process

ePTFE begins as PTFE fine powder resin. This resin is processed and then physically stretched, or "expanded," under specific conditions.

This mechanical expansion pulls the material apart, transforming the solid structure into an intricate network of microscopic fibers connected at various points, known as nodes.

The Resulting Structure

The final material is a microporous 3D web. This structure is often described as having a texture similar to a dense marshmallow—it is soft, flexible, and highly conformable.

The size of the pores and the density of the material can be precisely controlled during manufacturing, allowing for customization into forms like sheets, rods, and tubes for specific applications.

The Significance of Pores

These microscopic pores are the key differentiator between PTFE and ePTFE. They are small enough to block liquid water but large enough to allow air and water vapor to pass through.

This property is fundamental to ePTFE's use in applications requiring airflow, such as venting, medical implants, and high-performance filtration.

Key Properties Derived from its Structure

The unique web-like structure of ePTFE gives it a powerful combination of physical, chemical, and mechanical properties.

Exceptional Chemical & Thermal Stability

As a derivative of PTFE, ePTFE is chemically inert and resistant to nearly all caustic chemicals.

It maintains its integrity across an extremely wide temperature range, typically from -240°C to +250°C (-400°F to +482°F), making it ideal for severe environments. It is also non-flammable.

Unique Mechanical Characteristics

Unlike rigid PTFE, ePTFE is soft, compressible, and conformable. This allows it to create excellent seals on irregular surfaces.

The material has a very low coefficient of friction, giving it a non-stick surface. It is also highly resistant to creep (cold flow) and mechanical degradation.

Hydrophobicity and Surface Properties

ePTFE is inherently hydrophobic, meaning it repels water at low pressures. This property, combined with its porous nature, allows it to be both waterproof and breathable.

Its non-stick characteristics also facilitate the easy removal of particulate matter captured on its surface in filtration applications.

Electrical and Environmental Resistance

ePTFE has a low dielectric constant, making it a valuable electrical insulator in certain high-frequency applications.

The material is also UV resistant, ensuring it does not degrade when exposed to sunlight over long periods.

Understanding the Trade-offs

While ePTFE is a high-performance material, its specialized nature comes with practical considerations.

Mechanical Strength vs. Porosity

The softness and flexibility of ePTFE mean it does not have the rigidity or high tensile strength of a solid material. Its mechanical properties are directly linked to its density and porosity.

Susceptibility to "Wet-Out"

While hydrophobic, the pores can become saturated by liquids with very low surface tension or under high pressure. This condition, known as "wet-out," can eliminate the material's breathability.

Cost and Processing

The complex expansion process makes ePTFE a premium material with a higher cost than standard PTFE or other common polymers.

Making the Right Choice for Your Goal

Selecting ePTFE is a strategic decision based on leveraging its unique structural benefits for a specific performance goal.

- If your primary focus is advanced filtration or venting: The microporous structure provides an ideal barrier that allows air to pass through while blocking liquids and contaminants.

- If your primary focus is sealing in harsh environments: Its chemical inertness, extreme temperature range, and soft conformability make it a superior gasket material.

- If your primary focus is a medical device or implant: The biocompatibility, chemical inertness, and porous structure of ePTFE are its most critical assets.

By understanding the direct link between ePTFE's expanded structure and its resulting properties, you can confidently apply it to solve the most demanding engineering challenges.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Structure | 3D web of microscopic fibers and nodes | Creates a porous, breathable membrane |

| Chemical Resistance | Inert to nearly all caustic chemicals | Ideal for harsh environments |

| Temperature Range | Stable from -240°C to +250°C | Performs in extreme heat and cold |

| Hydrophobicity | Repels water while allowing vapor transmission | Waterproof and breathable |

| Conformability | Soft, compressible, and flexible | Excellent for sealing irregular surfaces |

Need a custom ePTFE solution for your demanding application?

KINTEK specializes in the precision manufacturing of PTFE and ePTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a component that perfectly leverages ePTFE's unique properties for superior performance.

Contact our experts today to discuss how we can bring your project to life.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key properties of PTFE? Unmatched Performance for Extreme Industrial Environments

- What are the three main fluoropolymers? PTFE, FEP, and PFA Compared for Your Industry

- What makes PTFE chemically stable? Discover the Science Behind Its Unmatched Inertness

- What is the electrical insulation capability of PTFE? Unmatched Reliability for Demanding Applications

- How is PTFE fine powder resin produced? The Key Role of Dispersion Polymerization

- What are the key properties that make PTFE commercially valuable? Unmatched Chemical Resistance & Low Friction

- What are the chemical and physical properties of ePTFE? The Ultimate Guide to a High-Performance Polymer

- What are the thermal properties of Teflon (PTFE)? Mastering Performance from Cryogenic to High Heat