To put it simply, CNC machining is used with Teflon plastic sheets to precisely fabricate high-performance, custom components for demanding industrial environments. This automated process cuts, drills, and shapes Teflon (PTFE) into finished parts like seals, gaskets, bearings, and electrical insulators that would be difficult to create with other methods. It ensures consistent quality and allows for mass customization of parts that must meet exact specifications.

Teflon is an exceptional engineering material, but its unique properties—softness, poor heat conductivity, and a tendency to deform—make it challenging to machine. Success depends entirely on using specialized techniques to manage heat, pressure, and the material's inherent flexibility.

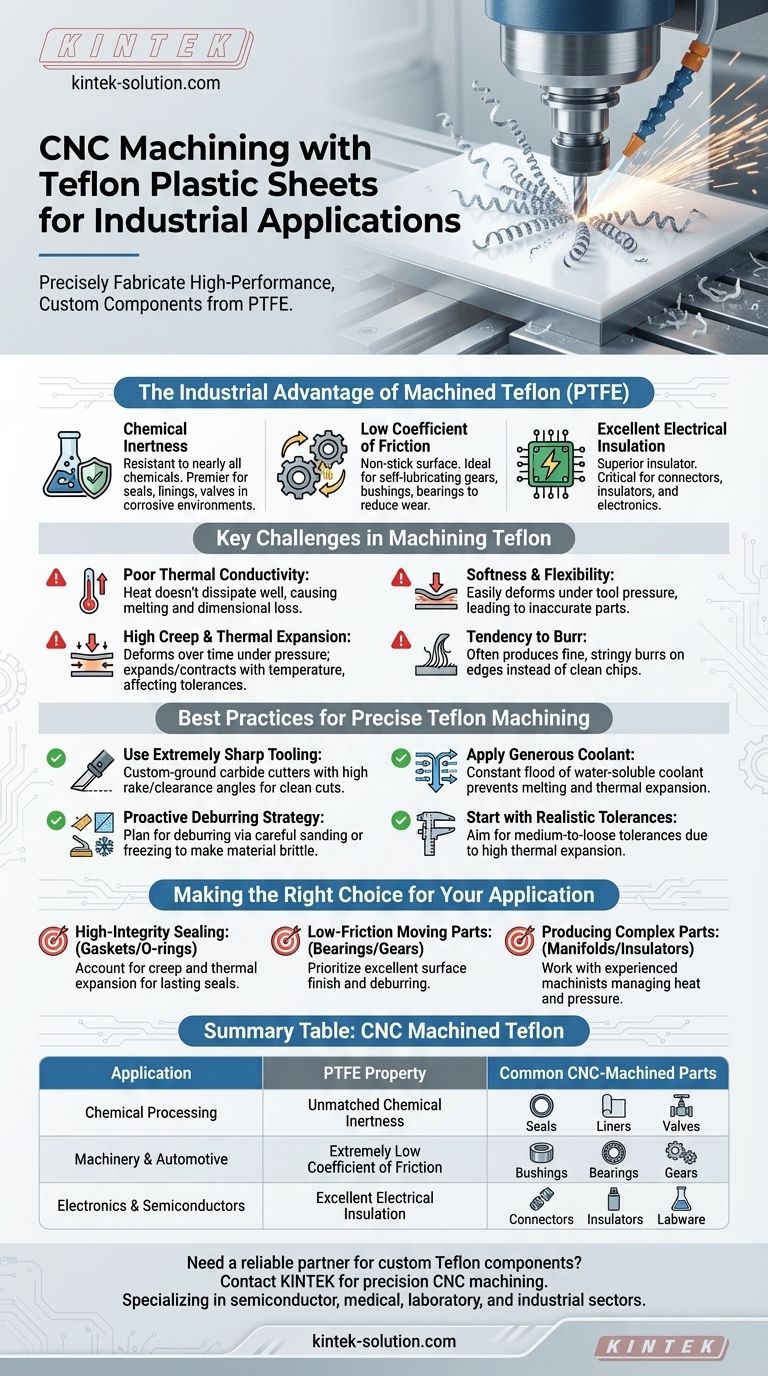

The Industrial Advantage of Machined Teflon

Teflon, or Polytetrafluoroethylene (PTFE), is chosen when other materials fail. Its properties make it indispensable in sectors from aerospace to food processing.

Unmatched Chemical Inertness

Teflon is resistant to nearly all industrial chemicals and solvents. This makes it a premier choice for seals, linings, and valve components used in corrosive environments.

Extremely Low Coefficient of Friction

Its famously non-stick surface is ideal for creating self-lubricating parts. CNC-machined gears, bushings, and bearings made from Teflon reduce wear and require minimal maintenance.

Excellent Electrical Insulation

Teflon is a superior electrical insulator, making it a critical material for manufacturing connectors, insulators, and other components in the electronics industry.

Key Challenges in Machining Teflon

Machining Teflon is unlike working with metals or harder plastics. Its unique characteristics demand a specific approach to avoid common failures.

Poor Thermal Conductivity

Teflon does not dissipate heat well. The friction from a cutting tool can quickly cause localized melting, ruining the part's dimensions and surface finish.

Softness and Flexibility

The material's softness means it can easily deform or compress under tool pressure. An aggressive machining approach will result in inaccurate parts.

High Creep and Thermal Expansion

Teflon has a high tendency to creep, meaning it deforms over time when under pressure. It also expands and contracts significantly with temperature changes, making it difficult to hold very tight tolerances.

The Tendency to Burr

Due to its softness, Teflon doesn't create clean "chips" like metal. Instead, it often produces fine, stringy burrs on part edges that must be removed in a separate step.

Best Practices for Precise Teflon Machining

To overcome its challenges, machinists rely on a set of proven techniques that accommodate the material's properties.

Use Extremely Sharp Tooling

Dull tools will push and tear the material rather than cut it cleanly. Very sharp, custom-ground carbide cutters with high rake and clearance angles are essential for good chip removal and a clean surface.

Apply Generous Coolant

A constant flood of water-soluble coolant is non-negotiable. It serves the critical function of removing heat from the cutting zone, preventing melting and thermal expansion.

Plan a Proactive Deburring Strategy

Because burrs are inevitable, a plan for removing them is part of the job. Post-machining processes like careful manual sanding or freezing the part to make it brittle can help create a clean, burr-free edge.

Start with Realistic Tolerances

While CNC machining is precise, Teflon's high thermal expansion makes holding ultra-tight tolerances difficult. It is often best to aim for medium-to-loose tolerances unless absolutely necessary for the application.

Making the Right Choice for Your Application

Successfully using machined Teflon requires aligning the design and process with the intended goal.

- If your primary focus is high-integrity sealing (gaskets, O-rings): Design your parts with an understanding of Teflon's creep and thermal expansion to ensure a lasting seal under operational pressure and temperature.

- If your primary focus is low-friction moving parts (bearings, gears): Prioritize an excellent surface finish by insisting on sharp tooling and a thorough deburring process.

- If your primary focus is producing complex parts (manifolds, insulators): Work with a machinist experienced with Teflon who can manage heat buildup and tool pressure to maintain dimensional accuracy throughout the process.

Understanding these principles transforms Teflon from a challenging material into a high-performance solution for your most critical components.

Summary Table:

| Application | Teflon (PTFE) Property Utilized | Common CNC-Machined Parts |

|---|---|---|

| Chemical Processing | Unmatched Chemical Inertness | Seals, Liners, Valve Components |

| Machinery & Automotive | Extremely Low Coefficient of Friction | Bushings, Bearings, Gears |

| Electronics & Semiconductors | Excellent Electrical Insulation | Connectors, Insulators, Labware |

Need a reliable partner for your custom Teflon components?

At KINTEK, we specialize in precision CNC machining of PTFE for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We understand the unique challenges of working with Teflon and employ best practices—like sharp tooling and proactive heat management—to deliver high-quality seals, liners, labware, and more.

We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications for performance and durability.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications