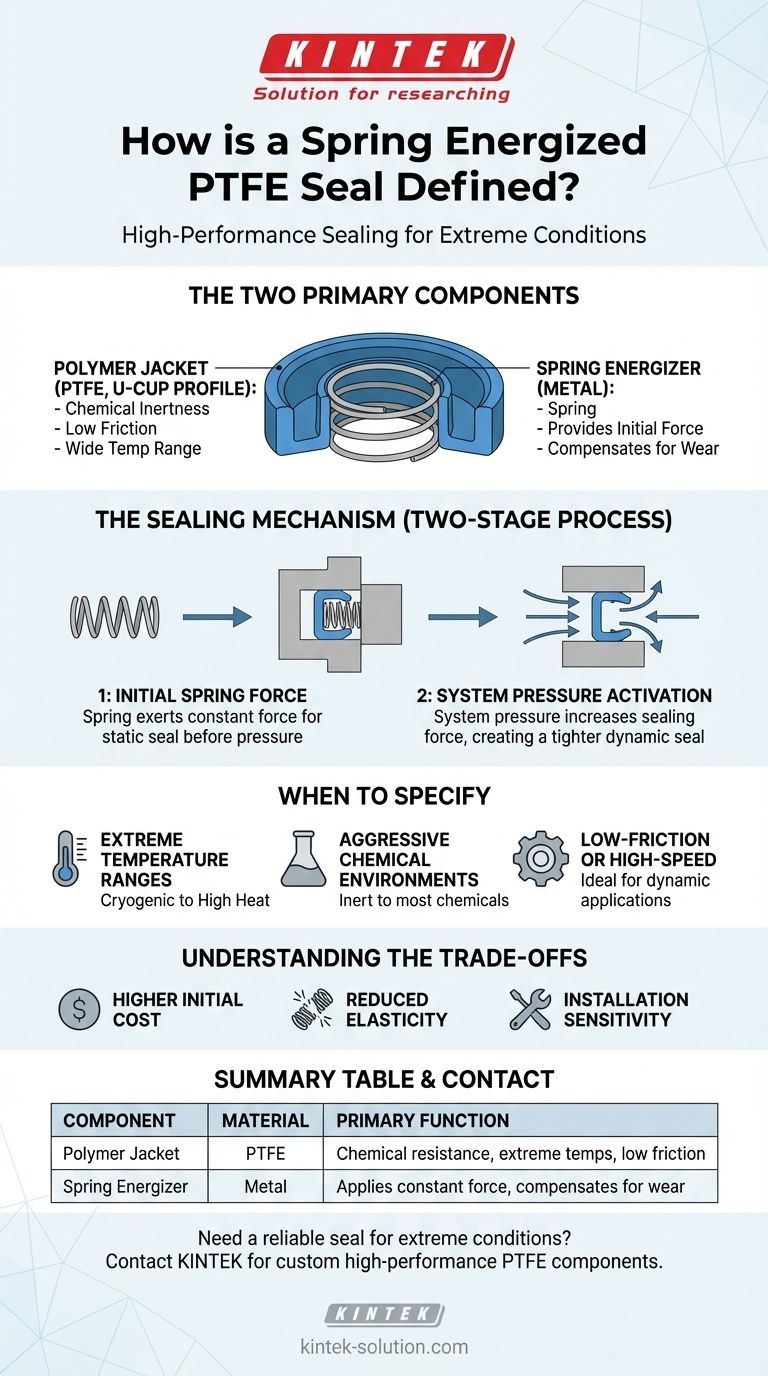

At its core, a spring energized PTFE seal is a high-performance sealing device engineered for extreme conditions where standard elastomeric seals would fail. It consists of a durable polymer jacket, typically made of Polytetrafluoroethylene (PTFE), and a corrosion-resistant metal spring energizer that applies constant force to the sealing lips.

This design creates a reliable seal by using the spring for initial contact and then leveraging system pressure for a tighter, more dynamic seal. It is a problem-solving component for applications involving extreme temperatures, aggressive chemicals, or critical friction requirements.

Deconstructing the Spring Energized Seal

To understand its function, it's best to look at its two primary components: the jacket and the energizer. Each plays a distinct and critical role in creating a robust seal.

The Polymer Jacket

The outer shell, or jacket, is the primary material that contacts the sealing surfaces. It's most commonly made from PTFE or other high-performance polymers.

This material is chosen for its exceptional properties, including a vast operating temperature range, near-universal chemical inertness, and a very low coefficient of friction. The jacket is machined into a "U-cup" profile, which features flexible lips that can be forced outward.

The Spring Energizer

Inside the jacket's U-shaped cavity sits a metal spring. This spring is the engine of the seal.

Its purpose is to provide the initial mechanical force needed to push the jacket's lips against the sealing surfaces. This ensures a tight seal even at very low system pressures and compensates for material wear and thermal expansion over the seal's life.

The Sealing Mechanism Explained

The effectiveness of this seal comes from a two-stage process that combines mechanical spring force with system pressure.

Stage 1: Initial Spring Force

When installed, the spring is compressed, exerting a constant outward force on the lips of the PTFE jacket. This creates a secure static seal against the hardware surfaces before any system pressure is applied.

Stage 2: System Pressure Activation

Once the system is pressurized, the fluid enters the U-shaped cavity of the seal. This pressure acts on the inner surfaces of the jacket lips, dramatically increasing the sealing force. The higher the system pressure, the tighter the seal becomes.

When to Specify a Spring Energized Seal

These seals are not general-purpose replacements for O-rings. They are specialized components designed to solve specific engineering challenges that commodity seals cannot.

Extreme Temperature Ranges

Standard elastomers can become brittle at cryogenic temperatures or degrade in high heat. PTFE seals maintain their integrity and sealing capability across an exceptionally wide temperature range.

Aggressive Chemical Environments

PTFE is virtually inert to most industrial chemicals and solvents. This makes spring energized seals essential for applications in chemical processing, oil and gas, and aerospace where harsh media is present.

Low-Friction or High-Speed Applications

The inherently low friction of the PTFE jacket makes these seals ideal for dynamic applications, such as in piston, rod, or rotary configurations. They reduce drag, prevent stick-slip, and minimize heat generation.

Understanding the Trade-offs

While highly effective, these seals come with specific considerations that are critical for successful implementation.

Higher Initial Cost

The advanced materials and manufacturing processes make spring energized seals significantly more expensive than standard elastomeric seals. Their cost is justified by their performance and the prevention of costly failures in critical systems.

Reduced Elasticity

PTFE is a much more rigid material than rubber. It is less forgiving of imperfections in hardware surface finishes and requires tighter tolerances to ensure a proper seal.

Installation Sensitivity

The polymer jacket can be damaged if not installed with care. Using proper tools and techniques is essential to avoid scratching or gouging the sealing lips, which would compromise performance.

Making the Right Choice for Your Application

Selecting a seal requires matching the component's capabilities to the system's demands.

- If your primary focus is reliability in extreme temperatures or chemical media: A spring energized PTFE seal is the definitive choice where standard seals have proven inadequate.

- If your primary focus is minimizing friction in a dynamic system: The low-friction properties of the PTFE jacket offer a distinct performance advantage over elastomeric seals.

- If your primary focus is a standard, low-cost static application: A traditional O-ring or elastomeric seal is likely the more practical and cost-effective solution.

Ultimately, choosing a spring energized seal is an engineering decision to ensure operational integrity when conditions are simply too demanding for conventional solutions.

Summary Table:

| Component | Material | Primary Function |

|---|---|---|

| Polymer Jacket | PTFE | Provides chemical resistance, handles extreme temperatures, and offers low friction. |

| Spring Energizer | Corrosion-resistant metal | Applies constant force for initial sealing and compensates for wear. |

Need a reliable seal for extreme conditions? KINTEK specializes in manufacturing high-performance PTFE components, including custom spring energized seals for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your seals meet the most demanding specifications, from prototypes to high-volume orders. Contact us today to discuss your application and ensure operational integrity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What advantages do Teflon sheets have over metal sheets? Discover Unmatched Chemical & Non-Stick Properties

- How does the temperature range of PTFE seals benefit various industries? Ensure Reliability from -200°C to 250°C

- What applications are suitable for bronze-filled PTFE? Enhance High-Load Performance with Durable PTFE

- How does the flexibility of PTFE expansion bellows compare to metal bellows? A Guide to Superior Movement Absorption

- What improvements do 25% carbon-filled PTFE bushings offer? Boost Strength, Wear & Static Dissipation

- Why is CNC machining ideal for manufacturing Teflon parts? Unlock Precision Without Compromising Material Integrity

- How does PTFE enhance baseball equipment? Unlock Faster Swings and Longer-Lasting Gear

- How does PTFE gland packing differ from other PTFE packing types? Discover the Right Sealing Solution