In short, PTFE sheets are bonded to metal tanks using specialized adhesives. This process is only possible because the backing of the PTFE sheet is chemically treated to create a bondable surface, overcoming PTFE's inherent non-stick nature.

The method of attachment—adhesive bonding—is straightforward, but the success of a PTFE sheet lining depends entirely on understanding its specific limitations. It is a specialized solution that is not suitable for all applications, particularly those involving vacuum pressure or small, complex tank geometries.

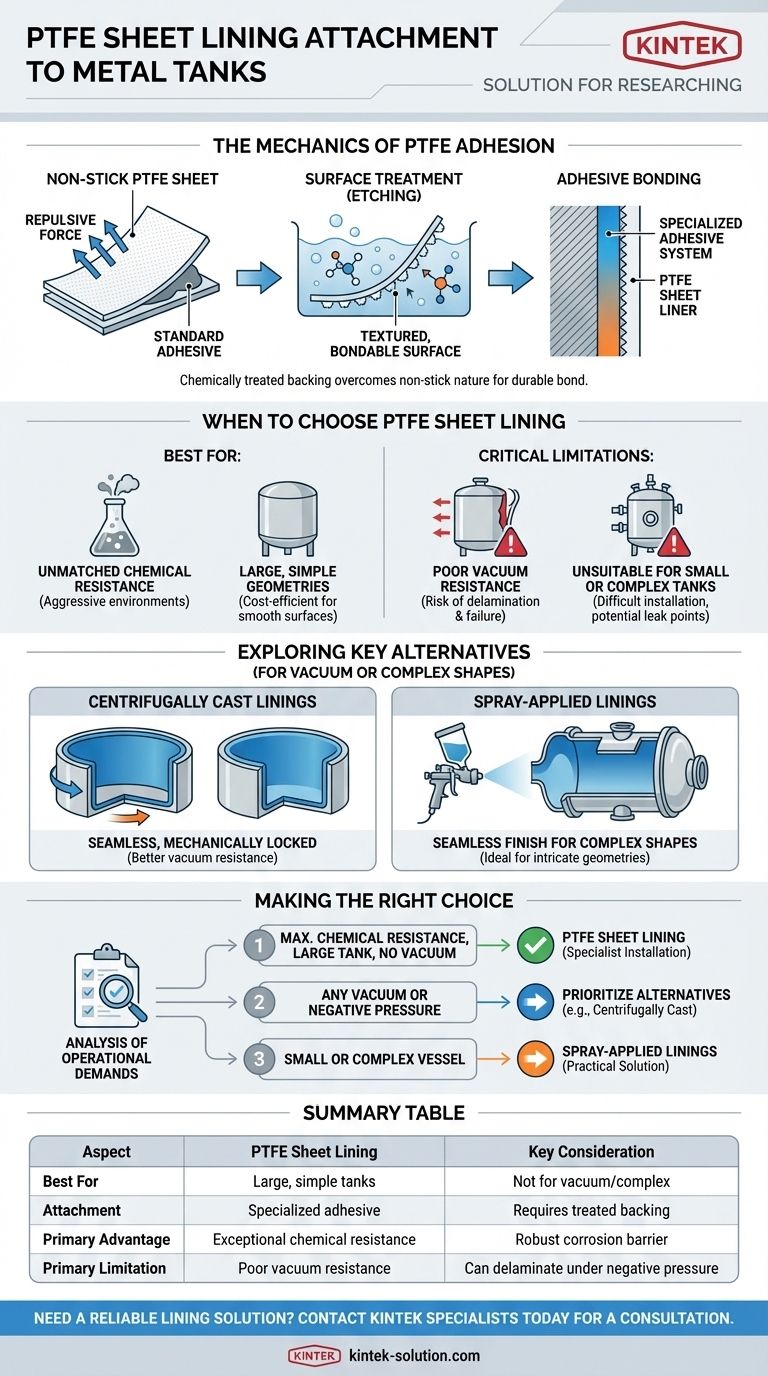

The Mechanics of PTFE Adhesion

Attaching a material famous for being non-stick requires a very specific approach. The process is less about the adhesive itself and more about preparing the PTFE to accept that adhesive.

The Challenge of Bonding to PTFE

Polytetrafluoroethylene (PTFE) has extremely low surface energy. This is what gives it its characteristic non-stick, low-friction properties. It also means that standard adhesives have nothing to "grip," causing them to peel away easily.

The Critical Role of Surface Treatment

To solve this, the back of the PTFE sheet undergoes a chemical treatment process, often called etching. This process alters the molecular structure of the PTFE surface, creating a texture that is receptive to bonding with an adhesive.

The Adhesive System

Once the PTFE sheet is treated, a specialized, high-performance adhesive system is used. This adhesive is formulated to create a durable, chemically resistant bond between the prepared PTFE backing and the properly prepared metal surface of the tank.

When to Choose PTFE Sheet Lining

PTFE sheet lining is an excellent choice for specific scenarios but is not a universal solution. Its strengths lie in its material properties when applied in the right environment.

Unmatched Chemical Resistance

The primary reason to select a PTFE lining is for its exceptional resistance to a wide range of aggressive chemicals, even at high temperatures. It provides a robust barrier in highly corrosive environments.

Ideal for Large, Simple Geometries

This method is most effective and cost-efficient when lining large tanks with smooth, simple internal surfaces. Applying large, flat sheets is more practical than attempting to fit them into complex shapes.

Understanding the Trade-offs and Limitations

Objectively, the limitations of PTFE sheet lining are as important as its benefits. Ignoring them is a common cause of failure.

Limited Vacuum Resistance

This is the most critical drawback. PTFE sheet linings have poor resistance to vacuum (negative pressure). A vacuum inside the tank can easily pull the liner away from the metal wall, causing bubbles, delamination, and catastrophic failure.

Unsuitability for Small or Complex Tanks

Lining small tanks or vessels with intricate nozzle configurations and internal structures is extremely difficult and impractical with rigid sheets. The number of seams required introduces potential points of failure.

The Need for Specialization

Applying a PTFE sheet lining is not a general fabrication task. It must be performed by specialized companies with experience in surface preparation, etching, and bonding techniques to ensure a successful and long-lasting application.

Exploring Key Alternatives

If your application involves vacuum pressure or complex shapes, other lining technologies are superior.

Centrifugally Cast Linings

In this process, a polymer is rotationally cast inside the vessel, creating a thick, seamless lining that is mechanically locked into place. This method offers far better vacuum resistance than bonded sheets.

Spray-Applied Linings

High-performance fluoropolymer coatings can be sprayed onto the interior of a tank. This method creates a seamless finish and is ideal for lining small or geometrically complex vessels that are unsuitable for sheet lining.

Making the Right Choice for Your Application

Selecting the correct lining technology requires a clear analysis of your operational demands, not just the chemical environment.

- If your primary focus is maximum chemical resistance in a large tank with no vacuum conditions: PTFE sheet lining is a strong and appropriate choice, provided it is installed by specialists.

- If your application involves any level of vacuum or negative pressure: You must prioritize alternatives like centrifugally cast or other mechanically robust lining systems.

- If you need to line a small or geometrically complex vessel: Spray-applied linings are almost always the more practical and reliable solution.

Ultimately, matching the lining technology to the specific mechanical and chemical stresses of your process is the key to ensuring long-term tank integrity.

Summary Table:

| Aspect | PTFE Sheet Lining | Key Consideration |

|---|---|---|

| Best For | Large, simple tanks with aggressive chemicals | Not suitable for vacuum or complex geometries |

| Attachment Method | Specialized adhesive bonding | Requires chemically treated PTFE backing |

| Primary Advantage | Exceptional chemical resistance | Provides a robust barrier against corrosion |

| Primary Limitation | Poor vacuum resistance | Can delaminate under negative pressure |

Need a reliable lining solution for your chemical process tank?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom-fabricated liners for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your tank lining is matched perfectly to your application's chemical and mechanical demands, from prototype to high-volume production.

Contact our specialists today for a consultation on your specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What makes expanded PTFE gaskets more suitable for sealing applications than pure PTFE gaskets? Solve Cold Flow for Reliable Seals

- What are the advantages of a PTFE rotary lip seal not being spring-energized? Achieve Superior High-Speed Performance

- What are the advantages of using PTFE guide strips in industrial applications? Enhance Equipment Life & Efficiency

- How can dimensional stability be maintained in machined PTFE parts? Master Precision Machining & Stress Relief

- What are the main differences between RPTFE and standard PTFE for valve seats? Choose the Right Material for Your System

- How do rubber gaskets compare to PTFE gaskets? Choose the Right Seal for Your Application

- What makes PTFE an excellent choice for gaskets, rings, and bearings? Unlock Unmatched Reliability with KINTEK PTFE

- What is the advantage of PTFE's self-lubricating properties in shaft seals? Achieve Reliable, Maintenance-Free Performance