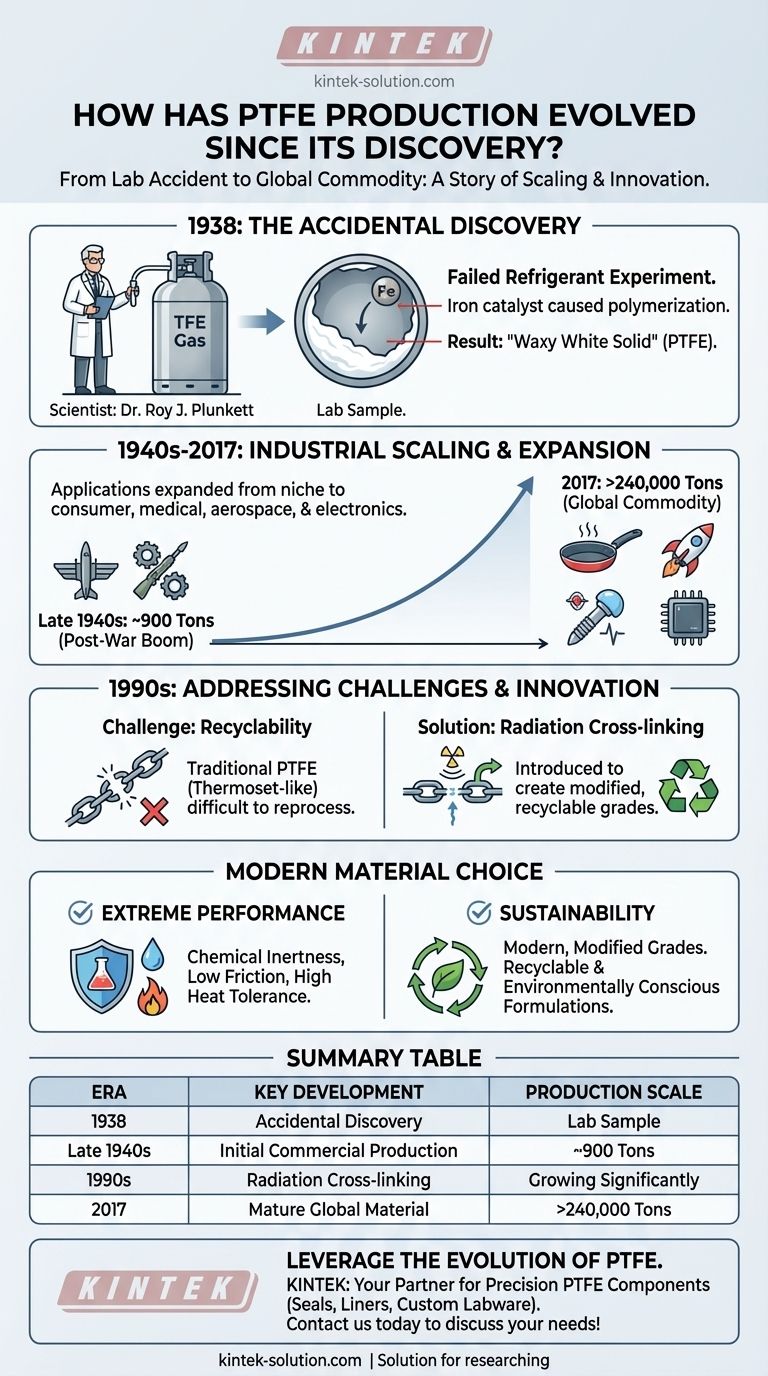

From lab accident to global commodity, the evolution of Polytetrafluoroethylene (PTFE) production has been a story of massive scaling and material science innovation. Initially discovered by chance in 1938, production grew from just 900 tons in the late 1940s to over 240,000 tons by 2017. This expansion was driven not only by increased manufacturing capacity but also by key technological advancements, such as the introduction of radiation cross-linking in the 1990s to improve its recyclability.

The history of PTFE is not just about producing more of a useful material. It's about a continuous effort to refine its properties, expand its applications, and address its lifecycle challenges, transforming it from a scientific curiosity into a foundational industrial polymer.

The Accidental Discovery That Started It All

The origin of PTFE is a classic story of an unexpected scientific breakthrough. It was not the result of a targeted research program but a fortunate accident.

A Failed Refrigerant Experiment

In 1938, Dr. Roy J. Plunkett, a chemist at DuPont, was researching new, non-toxic refrigerants. He was working with a gas called tetrafluoroethylene (TFE).

The Role of an Unseen Catalyst

Plunkett stored the TFE gas in a metal pressure cylinder. When he later opened the valve, he found that no gas came out, even though the cylinder's weight indicated it was still full. The iron from the container's interior had inadvertently acted as a catalyst, causing the TFE gas molecules to polymerize.

Identifying the "Waxy White Solid"

Upon cutting the cylinder open, Plunkett and his assistant discovered a waxy, white powder with incredibly slippery properties. This new substance was Polytetrafluoroethylene, a polymer that would later be trademarked as Teflon.

From Lab Curiosity to Industrial Scale

The unique properties of PTFE—extreme chemical resistance, low friction, and high heat tolerance—made it immediately valuable, but scaling production was a gradual process.

The Post-War Production Boom

Commercial production began in the 1940s, but it remained a niche, high-cost material for years. Output started at around 900 tons annually in the post-war era.

As manufacturing processes were refined and demand grew, production scaled exponentially, exceeding 240,000 tons by 2017.

Expanding Applications

Initially confined to specialized industrial and military uses (like the Manhattan Project), PTFE's applications expanded dramatically over the decades. It moved into consumer goods, most famously as non-stick coatings for cookware, as well as into medical, aerospace, and electronics industries.

Understanding the Trade-offs

The remarkable growth and utility of PTFE also brought challenges, which have prompted further evolution in its production and formulation.

The Challenge of Recyclability

Traditional PTFE is a thermoset-like fluoropolymer, meaning it is very difficult to melt and reprocess like common thermoplastics. This durability makes it valuable in application but also creates end-of-life waste challenges.

The Drive for Innovation

The difficulty in recycling spurred new research. The development of radiation cross-linking in the 1990s was a direct response to this problem, creating modified PTFE grades that were easier to break down and recycle.

This shows a key evolutionary trend: adapting the core material to meet modern sustainability and circular economy demands.

How This History Informs Material Choice Today

Understanding PTFE's journey from a lab accident to a highly engineered material provides critical context for its modern use.

- If your primary focus is extreme performance: Recognize that the fundamental properties of chemical inertness and low friction, discovered by accident in 1938, remain the core reasons for choosing PTFE today.

- If your primary focus is sustainability: Seek out modern, modified grades of PTFE, as the industry's evolution shows a clear trend toward creating more recyclable and environmentally conscious formulations.

By appreciating its past, you can better select the right form of this versatile polymer for the future.

Summary Table:

| Era | Key Development | Annual Production Scale |

|---|---|---|

| 1938 | Accidental discovery by Dr. Roy Plunkett | Lab sample |

| Late 1940s | Initial commercial production begins | ~900 tons |

| 1990s | Introduction of radiation cross-linking for recyclability | Growing significantly |

| 2017 | Mature, global industrial material | >240,000 tons |

Leverage the Evolution of PTFE for Your Precision Components

The journey of PTFE from a lab curiosity to a highly engineered polymer demonstrates its unmatched value for demanding applications. KINTEK is your partner in harnessing this advanced material. We specialize in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need extreme chemical resistance, low friction, or high-temperature performance, our expertise ensures you get the right PTFE solution, from prototypes to high-volume orders. Let us help you apply decades of material science innovation to your projects.

Contact KINTEK today to discuss your custom PTFE needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the benefits of PTFE's chemical resistance? Achieve Unmatched Reliability in Corrosive Environments

- What is the temperature range for PTFE's mechanical stability? From -200°C to +260°C

- What are the mechanical properties of filled PTFE? Enhanced Wear Resistance and Strength for Demanding Applications

- How do Teflon and UHMW compare in terms of applications and characteristics? Choose the Right High-Performance Polymer

- What are the friction and surface properties of PTFE? Discover the Science Behind Its Low Friction & Non-Stick Performance

- How does the molecular structure of Nylon differ from PTFE? A Guide to Polymer Properties

- How is Teflon utilized in the electronics industry? Ensuring Signal Integrity and Reliability

- What is Polytetrafluoroethylene (PTFE) commonly known as, and what are its properties? Discover the Power of Teflon