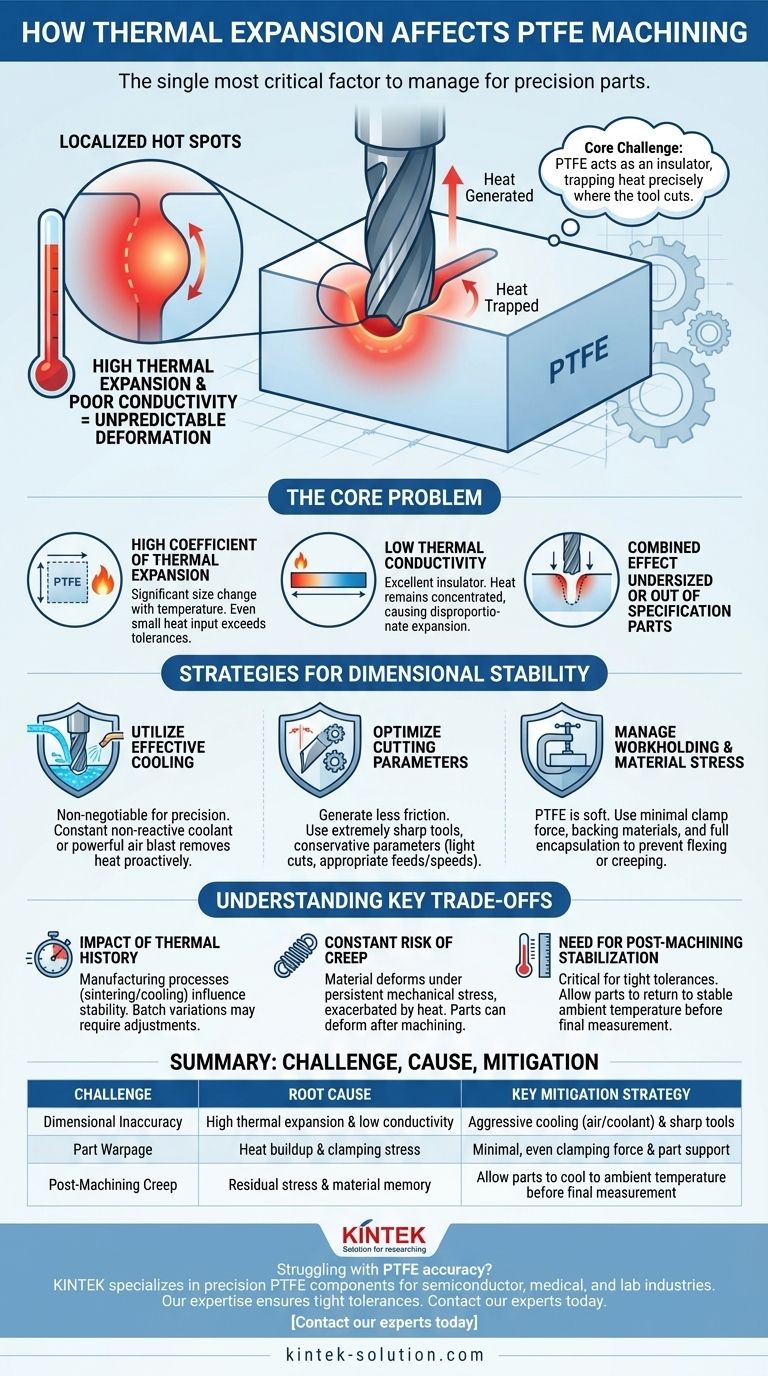

In short, thermal expansion is the single most critical factor to manage when machining Polytetrafluoroethylene (PTFE). Due to its high rate of thermal expansion and poor ability to conduct heat, the friction from cutting tools creates localized hot spots. This causes the material to expand unpredictably during the machining process, leading to significant dimensional inaccuracies once the finished part cools.

The core challenge with PTFE isn't just that it expands with heat, but that it acts as an insulator, trapping that heat precisely where the tool is cutting. Successful PTFE machining is therefore a practice in aggressive heat management, focusing on minimizing heat generation and maximizing its removal.

The Core Problem: Why PTFE Deforms

Understanding the specific material properties of PTFE is essential to controlling it. The challenge arises from two competing characteristics that work against the machinist.

High Coefficient of Thermal Expansion

PTFE expands and contracts more significantly with temperature changes than most other polymers and metals. Even a small change in temperature, such as that generated by a cutting tool, can cause a dimensional change that exceeds tight tolerances.

Low Thermal Conductivity

Unlike metals, which quickly dissipate heat throughout the material, PTFE is an excellent thermal insulator. This means heat generated by the cutting tool remains concentrated in a very small area, causing that specific point to expand disproportionately while the rest of the part remains stable.

The Combined Effect: Unpredictable Cuts

This combination is what makes the material so challenging. The tool heats a localized spot, that spot expands, and the cut is made on this temporarily larger dimension. As soon as the part cools, that area contracts, resulting in a feature that is undersized or out of specification.

Strategies for Dimensional Stability

To produce accurate PTFE components, your entire strategy must revolve around mitigating heat buildup at every stage of the process.

Utilize Effective Cooling

Because PTFE traps heat, an external cooling method is non-negotiable for precision work. A constant stream of non-reactive coolant or a powerful air blast directed at the tool-material interface is crucial for actively removing heat as it's generated.

Optimize Your Cutting Parameters

The goal is to generate less friction and therefore less heat in the first place. This is achieved by using extremely sharp tools with a high rake angle and employing conservative parameters—meaning lighter depths of cut, appropriate feed rates, and controlled spindle speeds.

Manage Workholding and Material Stress

PTFE is a soft material with low stiffness, making it susceptible to deformation from clamping pressure alone. Use minimal clamp force and, where possible, use backing materials or full encapsulation to support the workpiece and prevent it from flexing or creeping under either mechanical or thermal stress.

Understanding Key Trade-offs

Machining PTFE successfully requires acknowledging its inherent limitations and planning for them. Ignoring these factors can lead to inconsistent results and high scrap rates.

The Impact of Thermal History

The final physical properties of a PTFE blank are influenced by its manufacturing process, particularly the sintering and cooling cycle. Variations between material batches can lead to slight differences in stability, requiring minor adjustments to your machining process.

The Constant Risk of Creep

Creep is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress. With PTFE, this is exacerbated by heat. A part that is dimensionally accurate off the machine can slowly deform if it was machined under stress.

The Need for Post-Machining Stabilization

For parts with the tightest tolerances, it is critical to allow them to return to a stable ambient temperature before taking final measurements. Measuring a part while it is still warm from machining will give you a false reading.

Making the Right Choice for Your Goal

Your specific approach should be tailored to the primary requirements of the finished component.

- If your primary focus is tight tolerances: Prioritize aggressive, constant cooling and use multiple, very light finishing passes to minimize heat input.

- If your primary focus is preventing warpage on thin parts: Use minimal, evenly distributed clamping pressure and support the entire part with a fixture or backing plate.

- If your primary focus is process consistency across a large run: Maintain a stable shop floor temperature and use dedicated, exceptionally sharp tooling that is never used on other materials.

Ultimately, mastering heat management is the key to transforming PTFE from a challenging material into a predictable and reliable one.

Summary Table:

| Challenge | Root Cause | Key Mitigation Strategy |

|---|---|---|

| Dimensional Inaccuracy | High thermal expansion & low conductivity | Aggressive cooling (air/coolant) & sharp tools |

| Part Warpage | Heat buildup & clamping stress | Minimal, even clamping force & part support |

| Post-Machining Creep | Residual stress & material memory | Allow parts to cool to ambient temperature before final measurement |

Struggling with PTFE part accuracy? KINTEK specializes in precision machining of PTFE components (seals, liners, labware) for the semiconductor, medical, and laboratory industries. Our expertise in managing thermal expansion ensures your parts meet the tightest tolerances, from prototypes to high-volume orders. Contact our experts today to discuss your project and achieve reliable, dimensionally stable results.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability