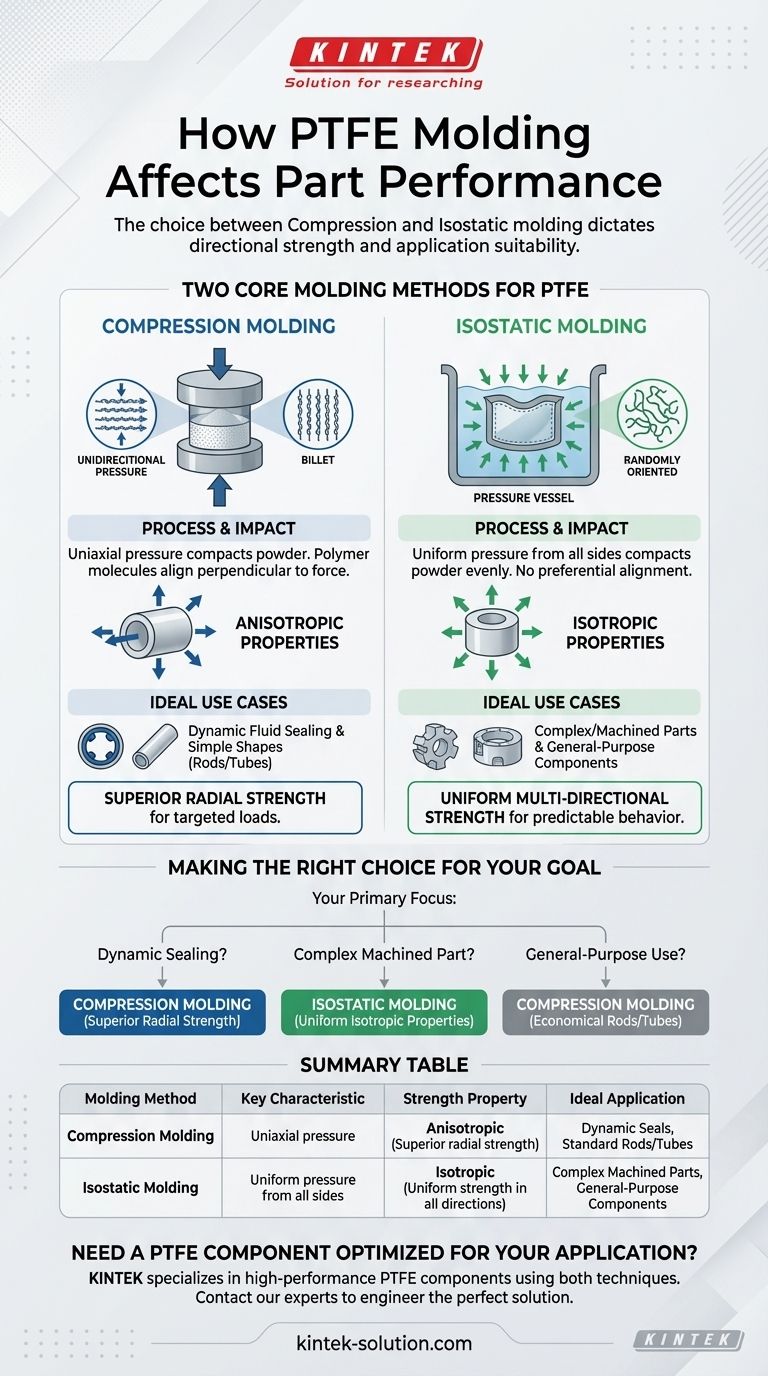

The method used to mold PTFE directly and significantly impacts the final part's mechanical properties. Specifically, the choice between compression and isostatic molding determines the directional strength of the material, which in turn dictates its suitability for different applications.

The core decision comes down to directionality. Compression molding creates parts with superior strength in one direction, making them ideal for specific loads like seals, while isostatic molding produces uniform, multi-directional strength for general-purpose or complex components.

The Two Core Molding Methods for PTFE

Understanding how each molding process works is key to grasping its effect on performance. The fundamental difference is how pressure is applied to the raw PTFE powder.

Compression Molding Explained

Compression molding involves compacting PTFE powder in a die using pressure applied from one direction, typically along a single axis. This is used to create simple shapes like solid cylinders (billets) or tubes.

The uniaxial pressure encourages the long-chain PTFE polymer molecules to align themselves perpendicular to the direction of the force.

The Impact on Performance

This molecular alignment means the finished part is anisotropic—it has different properties in different directions. A compression-molded part will have significantly higher mechanical properties, like tensile strength, in the radial direction (outward from the center) compared to the axial direction (along its length).

Isostatic Molding Explained

Isostatic molding places PTFE powder in a flexible mold, which is then submerged in a fluid. This fluid is pressurized, applying equal force to the powder from all directions simultaneously.

This uniform pressure compacts the powder evenly, without creating a preferential alignment of the polymer chains.

The Impact on Performance

The result is an isotropic part, meaning its mechanical properties are the same in every direction. The material offers consistent, predictable strength and behavior regardless of how it is oriented or machined.

Why This Matters for Your Application

The choice is not about which method is "better" overall, but which one produces the ideal properties for a specific engineering challenge.

The Ideal Use Case for Compression Molding

The superior radial strength of compression-molded PTFE makes it the definitive choice for dynamic fluid sealing applications. In a seal, the primary force is outward pressure against a housing. Compression molding directly enhances the material's ability to resist this force, leading to a longer-lasting, more effective seal.

The Ideal Use Case for Isostatic Molding

Isostatic molding is preferred for complex components or parts that will be extensively machined. Because its properties are uniform, you don't have to worry about creating a weak point by cutting into the material along a specific axis. It's ideal for parts experiencing stress from multiple or unpredictable directions.

Leveraging PTFE's Inherent Advantages

Both methods produce parts that benefit from PTFE's natural qualities, including an extremely low coefficient of friction for sliding applications, durability in harsh environments, and FDA approval for food-grade safety. The molding method simply optimizes the part's structural response.

Understanding the Trade-offs

Selecting a molding method involves balancing performance priorities against potential limitations.

Directional Strength vs. Uniformity

This is the central trade-off. Compression molding gives you exceptional, targeted performance in one direction at the expense of strength in another. Isostatic molding provides good, predictable performance in all directions, but without the specialized peak strength of a compression-molded part.

Geometry and Cost

Compression molding is highly efficient and affordable for producing simple, standard shapes like rods and tubes in high volumes. Isostatic molding can be more complex and costly but is better suited for creating larger billets or more intricate near-net shapes, which can reduce subsequent machining waste.

Making the Right Choice for Your Goal

Your application's primary demand should guide your decision.

- If your primary focus is dynamic sealing: Choose compression molding to leverage its superior radial mechanical properties, which directly counteract sealing pressures.

- If your primary focus is a complex machined part: Isostatic molding is the safer choice for its uniform, isotropic properties, ensuring predictable performance.

- If your primary focus is general-purpose use: Compression-molded rods and tubes often provide the most economical and effective solution for a wide range of non-critical applications.

By understanding how the molding process engineers the material's internal structure, you can select a PTFE component optimized for its specific operational demands.

Summary Table:

| Molding Method | Key Characteristic | Strength Property | Ideal Application |

|---|---|---|---|

| Compression Molding | Uniaxial pressure | Anisotropic (Superior radial strength) | Dynamic Seals, Standard Rods/Tubes |

| Isostatic Molding | Uniform pressure from all sides | Isotropic (Uniform strength in all directions) | Complex Machined Parts, General-Purpose Components |

Need a PTFE Component Optimized for Your Application?

Understanding the nuances of PTFE molding is critical for part performance. At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We leverage both compression and isostatic molding techniques to deliver the precise mechanical properties your project demands, from prototypes to high-volume production runs. Our focus on precision ensures your parts perform reliably in their specific environment.

Let's discuss your requirements and engineer the perfect solution. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What temperature range can PTFE-lined valves operate within? Key Limits for Safe & Reliable Performance

- What medical applications benefit from extruded PTFE rods? Precision Components for Surgical & Diagnostic Devices

- What is the Shore hardness and compression strength of PTFE? A Guide to Its Mechanical Limits

- What is the chemical composition of PTFE gaskets? Discover the Source of Its Superior Performance

- What makes PTFE lined valves suitable for handling aggressive media? Superior Chemical Resistance for Harsh Fluids

- What advantages do Teflon O-rings offer? Superior Sealing for Extreme Conditions

- What are the key characteristics of PTFE Enveloped Gaskets? Solve Demanding Sealing Challenges

- Why is it important to consider PTFE lining standards when selecting a supplier? Avoid Costly Failures