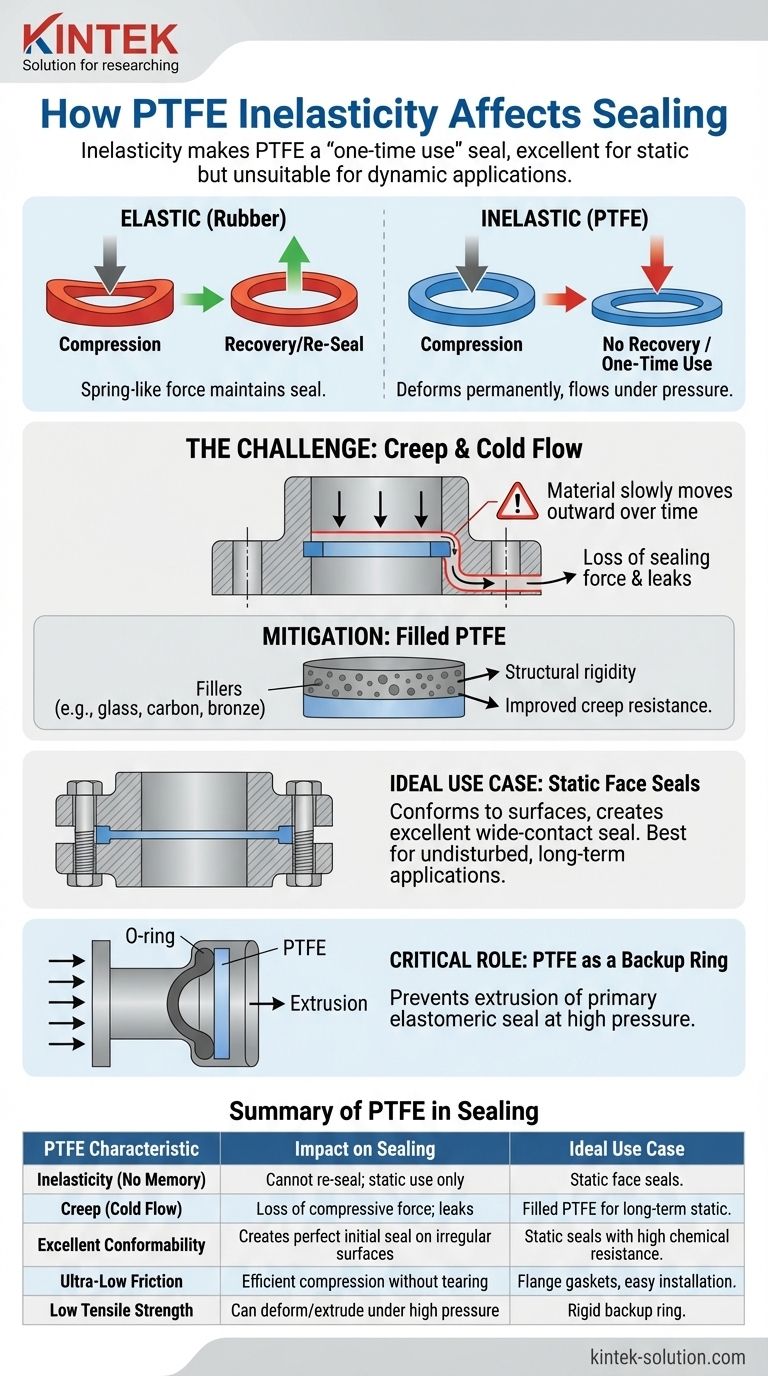

In short, the inelasticity of PTFE is its defining limitation in sealing applications. Because PTFE does not return to its original shape after being compressed, it is fundamentally a "one-time use" seal. Once deformed during installation, it loses its ability to effectively re-seal if the joint is opened and closed again, making it unsuitable for any dynamic or frequently serviced connection.

The core issue with PTFE's inelasticity is its lack of "memory." Unlike rubber, which springs back, PTFE flows under pressure and stays deformed. This makes it excellent for static, undisturbed seals but a point of failure in applications requiring rebound or reuse.

The "Compression Set" Principle of PTFE

The inability of a material to return to its original thickness after a compressive force is removed is known as compression set. While all materials exhibit this to some degree, PTFE's behavior is extreme.

Inelasticity vs. Elasticity in Sealing

An elastomeric seal, like a rubber O-ring, is effective because it pushes back against the mating surfaces. This "spring-like" force maintains a seal even with minor vibrations or temperature changes.

PTFE lacks this elastic recovery. When compressed, it conforms to the shape of the groove or flange but does not push back with the same force. It behaves like a rubber O-ring with a 100% compression set after just a single use.

The Impact on Dynamic Applications

This inelasticity makes pure PTFE seals entirely unsuitable for dynamic applications or those requiring frequent reuse.

A seal on a chamber door, for example, must decompress when opened and re-establish a seal when closed. A PTFE O-ring would be flattened on its first use and would likely fail to seal properly on the second cycle.

The Ideal Use Case: Static Face Seals

PTFE excels in static face seals or flange gaskets where the seal is installed, compressed, and left undisturbed.

In this scenario, the material flows into the microscopic imperfections of the flange faces, creating an excellent, wide-contact seal. It remains in this state, effectively preventing leaks until the equipment is scheduled for its next major service.

The Challenge of Creep and Cold Flow

A direct consequence of PTFE's inelasticity is a phenomenon known as creep, or cold flow. This is the tendency of the material to slowly deform and move away from the point of pressure over time.

How Creep Leads to Seal Failure

Under the sustained pressure of a bolted flange, the PTFE material can slowly flow outward. This movement reduces the initial compressive stress that created the seal.

Over time, this loss of sealing force can become significant enough to allow leaks, especially in systems with pressure or temperature cycles.

Mitigating Creep with Fillers

To combat cold flow, PTFE is often blended with fillers like glass fiber, carbon, bronze, or graphite.

These fillers act like an internal skeleton within the PTFE matrix. They provide structural rigidity, significantly improving the material's dimensional stability and resistance to creep, making it suitable for more demanding applications.

Using Inelasticity to an Advantage

While a limitation for primary seals, PTFE's properties are ideal for a critical supporting role in high-pressure systems.

PTFE as a Backup Ring

In high-pressure applications, a soft elastomeric O-ring can be squeezed into the clearance gap between moving parts, a failure known as extrusion.

A hard, inelastic PTFE backup ring is installed next to the O-ring. Under pressure, the O-ring expands but is blocked by the rigid PTFE ring, which is strong enough to resist being pushed into the gap. This allows a standard rubber O-ring to function at much higher pressures.

Understanding the Trade-offs

Choosing PTFE requires acknowledging its distinct benefits and limitations, which are often two sides of the same coin.

Benefit: Excellent Conformability

While it doesn't spring back, PTFE's ability to flow allows it to conform perfectly to irregular surfaces. This ensures it fills gaps and creates a large surface-contact seal upon initial installation.

Benefit: Ultra-Low Friction

PTFE's low coefficient of friction ensures that when a flange is tightened, the applied force goes directly into compressing the gasket. It doesn't get wasted overcoming friction, which could otherwise tear or displace the seal.

Limitation: High Pressure and Low Strength

Pure PTFE has low tensile strength. In high-pressure systems, it can be deformed or forced out of place without the support of fillers or a robust backup ring design.

Making the Right Choice for Your Goal

Your application dictates whether PTFE's inelasticity is an asset or a liability.

- If your primary focus is a reusable or dynamic seal (e.g., a lid or access door): Pure PTFE is unsuitable. You require an elastomeric material like Viton™ or Silicone that can rebound after each cycle.

- If your primary focus is a demanding static seal (e.g., a high-pressure chemical flange): A filled PTFE gasket is the correct choice to resist creep and maintain a long-term seal.

- If your primary focus is preventing seal extrusion at high pressure: Use a PTFE backup ring to support a primary elastomeric seal, combining the best properties of both materials.

By understanding PTFE's inelastic nature, you can leverage its unique properties for exceptionally reliable static sealing while avoiding failures in dynamic applications.

Summary Table:

| PTFE Characteristic | Impact on Sealing Application | Ideal Use Case |

|---|---|---|

| Inelasticity / No Memory | Cannot re-seal after compression; unsuitable for dynamic or reusable seals. | Static face seals and flange gaskets. |

| Creep / Cold Flow | Can lead to seal failure over time due to loss of compressive force. | Mitigated by using filled PTFE (glass, carbon, bronze). |

| Excellent Conformability | Creates a perfect, wide-contact seal on irregular surfaces upon installation. | Static seals requiring high chemical resistance. |

| Ultra-Low Friction | Applied force compresses the seal efficiently without tearing. | Flange gaskets where easy installation is key. |

| Low Tensile Strength | Can be deformed or extruded under high pressure without support. | Used as a rigid backup ring to support elastomeric seals in high-pressure systems. |

Need a Reliable PTFE Seal for Your Demanding Application?

Understanding the trade-offs of PTFE is the first step to selecting the right seal. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We help you leverage PTFE's strengths, like its superior chemical resistance and conformability, while mitigating its limitations through:

- Custom Fabrication: From prototypes to high-volume orders, we engineer solutions tailored to your specific static or high-pressure needs.

- Expert Material Selection: We recommend and supply filled PTFE compounds to combat creep and enhance performance.

- Precision Production: Ensure a perfect, reliable seal every time with components made to exacting standards.

Don't let seal failure compromise your process. Contact KINTALK today to discuss your application and get a solution that delivers long-term reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications