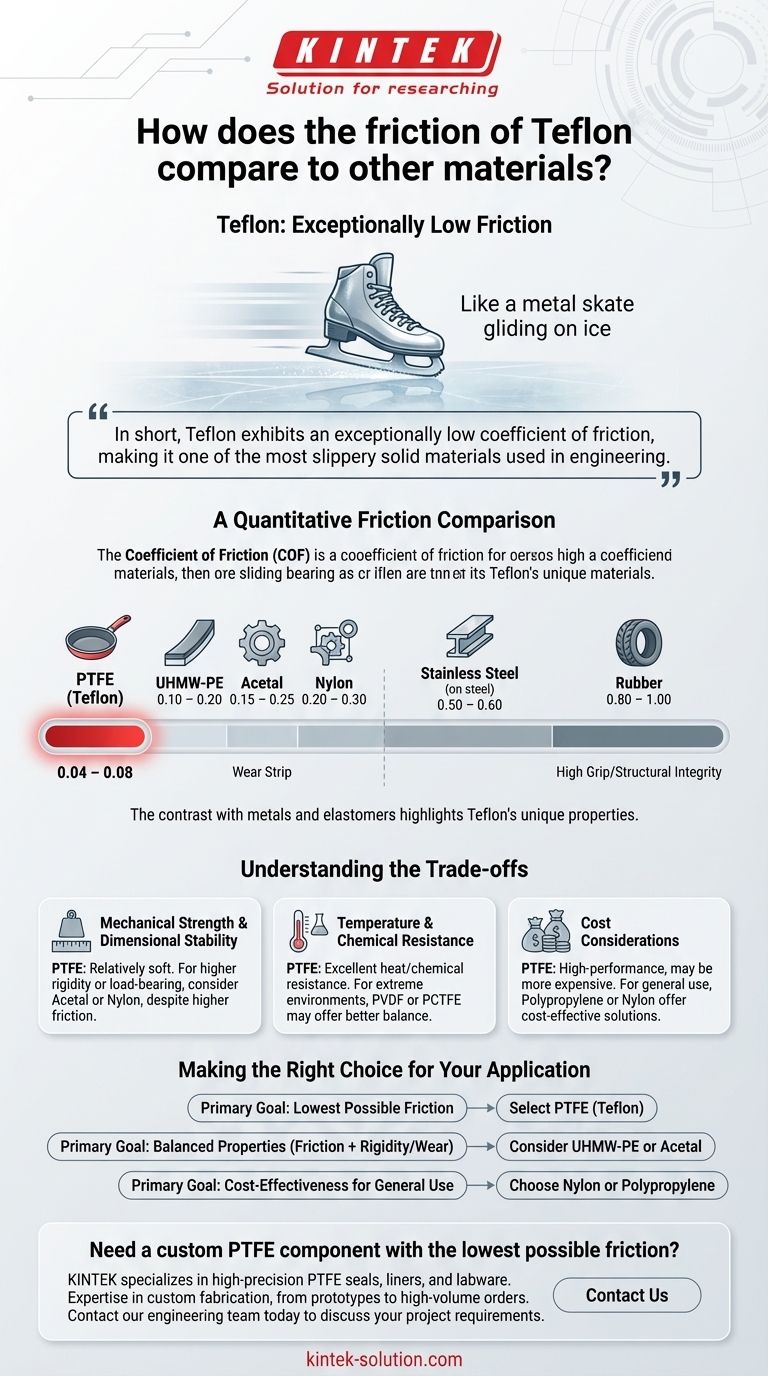

In short, Teflon exhibits an exceptionally low coefficient of friction, making it one of the most slippery solid materials used in engineering. Its friction is often compared to that of a metal skate gliding on ice. When measured against other common engineering plastics, metals, and elastomers, Teflon consistently demonstrates a significantly lower resistance to sliding motion.

The core reason for selecting a material goes beyond a single property. While Teflon (PTFE) is the benchmark for low friction, the optimal choice for any application requires balancing its slipperiness against other critical factors like mechanical strength, temperature resistance, and cost.

A Quantitative Friction Comparison

To understand the practical difference, we must look at the coefficient of friction (COF). This dimensionless value quantifies the ratio of the force of friction between two bodies to the force pressing them together; a lower number means a more slippery surface.

PTFE (Teflon) as the Benchmark

Polytetrafluoroethylene (PTFE), the chemical name for Teflon, has a dynamic COF typically in the range of 0.04 to 0.08.

This is an incredibly low value for a solid material, making it the go-to choice for applications like non-stick coatings, sliding bearings, and chemical-resistant seals where minimal resistance is paramount.

How Other Engineering Plastics Compare

While other plastics are used for low-friction applications, their COF values are notably higher than PTFE's.

- UHMW-PE (Ultra-High-Molecular-Weight Polyethylene): 0.10 – 0.20

- Acetal: 0.15 – 0.25

- Nylon: 0.20 – 0.30

These materials are often selected when properties like higher rigidity or abrasion resistance are needed in addition to low friction.

The Contrast with Metals and Elastomers

When compared to metals or rubbers, the difference becomes even more stark, highlighting Teflon's unique properties.

- Stainless Steel (on steel): 0.50 – 0.60

- Rubber: 0.80 – 1.00

These materials are designed for grip and structural integrity, not slipperiness, and their high COF values reflect this function.

Understanding the Trade-offs

Teflon's low friction is its defining feature, but it is not the ideal material for every situation. A true technical decision requires evaluating its properties in a broader context.

Mechanical Strength and Dimensional Stability

PTFE is a relatively soft material. In applications requiring high structural rigidity, load-bearing capacity, or precise dimensional stability under pressure, materials like Acetal or Nylon may be superior choices, despite their higher friction.

Temperature and Chemical Resistance

Teflon offers an excellent profile for both heat and chemical resistance. However, for specific extreme environments, other fluoropolymers like PVDF or PCTFE might offer a better balance of properties, even if their friction coefficients are slightly different.

Cost Considerations

As a high-performance polymer, PTFE can be more expensive than other plastics. For less demanding applications where the absolute lowest friction is not a hard requirement, materials like polypropylene or nylon can offer a more cost-effective solution.

Making the Right Choice for Your Application

Your final material selection depends entirely on the primary goal of your design.

- If your primary focus is achieving the lowest possible friction: PTFE is the undisputed benchmark and your clear first choice.

- If your primary focus is balancing low friction with improved rigidity and wear resistance: Consider materials like UHMW-PE or Acetal as strong alternatives.

- If your primary focus is cost-effectiveness for a general-purpose application: Standard plastics like Nylon or Polypropylene offer a reasonable balance of properties.

By understanding these critical trade-offs, you can select the material that provides the precise performance your design requires.

Summary Table:

| Material | Typical Coefficient of Friction (COF) |

|---|---|

| PTFE (Teflon) | 0.04 – 0.08 |

| UHMW-PE | 0.10 – 0.20 |

| Acetal | 0.15 – 0.25 |

| Nylon | 0.20 – 0.30 |

| Stainless Steel | 0.50 – 0.60 |

| Rubber | 0.80 – 1.00 |

Need a custom PTFE component with the lowest possible friction?

At KINTEK, we specialize in manufacturing high-precision PTFE components like seals, liners, and labware for the semiconductor, medical, and industrial sectors. We understand that achieving the right balance of low friction, mechanical strength, and chemical resistance is critical to your design's success.

Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component that delivers optimal performance for your specific application.

Contact our engineering team today to discuss your project requirements and get a solution that slides into place perfectly.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE considered a versatile material? Unmatched Chemical & Thermal Properties

- What are the disadvantages of PTFE? Key Limitations in High-Performance Applications

- What types of implants and prosthetics utilize polymers? The Essential Guide to Medical Materials

- How does PTFE perform in wet or oil-containing environments? Unmatched Hydrophobic & Oleophobic Reliability

- What are the key physical properties of PTFE? Unlock Its Extreme Performance for Demanding Applications

- What are the benefits of using fillers in PTFE? Enhance Wear, Strength, and Performance

- What makes PTFE suitable for food manufacturing and packaging? Ensure Safety and Efficiency

- What is PTFE chemically composed of? Discover the Simple Chemistry Behind Its Extreme Performance