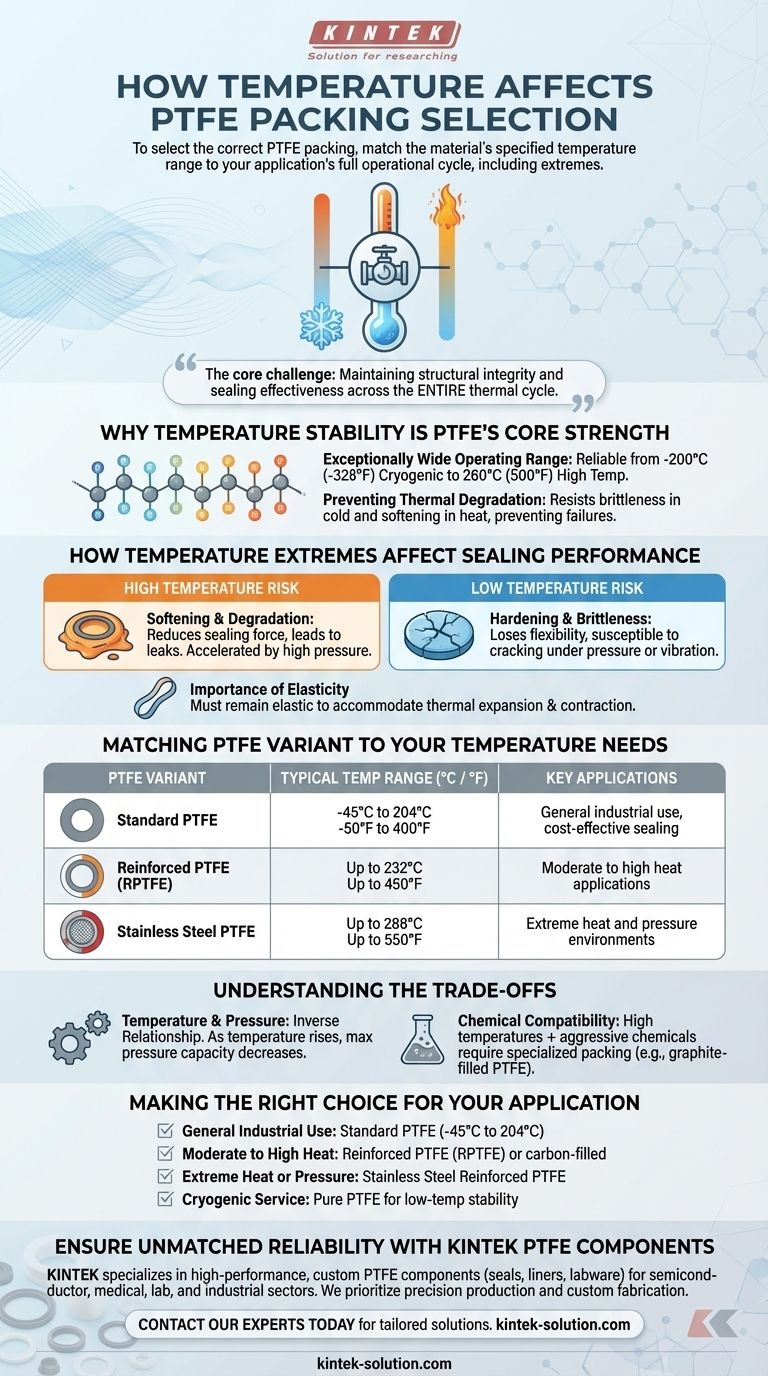

To select the correct PTFE packing, you must match the material's specified temperature range to the full operational range of your application, including both normal operating temperatures and any potential temperature extremes. While standard PTFE offers a remarkably wide range, specialized variants like reinforced or stainless steel-filled PTFE are necessary for applications involving higher heat to prevent material failure.

The core challenge is not simply finding a material that works at a single temperature, but one that maintains its structural integrity and sealing effectiveness across the entire thermal cycle of your equipment, from shutdown to peak operation.

Why Temperature Stability is PTFE's Core Strength

An Exceptionally Wide Operating Range

Polytetrafluoroethylene (PTFE) is renowned for its ability to maintain its properties across a vast temperature spectrum. It performs reliably in conditions where many other materials would fail.

This range extends from cryogenic temperatures as low as -200°C (-328°F) up to high temperatures of 260°C (500°F).

Preventing Thermal Degradation

Unlike many polymers that become brittle at low temperatures or soften significantly at high temperatures, PTFE maintains its structural integrity. This stability prevents failures caused by thermal expansion, contraction, or material degradation.

How Temperature Extremes Affect Sealing Performance

Choosing the wrong packing for your temperature range leads to predictable failure modes. Understanding these risks is critical for ensuring equipment reliability and safety.

The Risk of High Temperatures: Softening and Degradation

When PTFE packing is subjected to temperatures beyond its specified limit, it begins to soften. This reduces its ability to maintain a tight seal, leading to leaks.

This effect is accelerated when high temperatures are combined with high pressure, as the two factors work together to speed up material degradation.

The Risk of Low Temperatures: Hardening and Brittleness

At the other extreme, exposure to cryogenic or very low temperatures can cause the PTFE packing to harden and lose its flexibility.

A brittle packing material is susceptible to cracking under pressure or during equipment vibration, which can result in sudden and complete seal failure.

The Importance of Elasticity

A packing material must remain elastic enough to accommodate the microscopic expansion and contraction of metal components as they heat up and cool down. If the packing becomes permanently deformed by these cycles, it will lose its sealing force.

Matching the PTFE Variant to Your Temperature Needs

Not all PTFE packing is created equal. Fillers and reinforcements are used to enhance specific properties, most notably the maximum service temperature.

Standard PTFE: The Baseline

Standard, unfilled PTFE packing typically provides an excellent service range for a wide variety of applications, often cited as -45°C to 204°C (-50°F to 400°F).

Reinforced PTFE (RPTFE): A Step Up in Heat Resistance

By adding fillers like glass or carbon, Reinforced PTFE (RPTFE) offers slightly improved high-temperature performance, pushing the upper limit to around 232°C (450°F).

Stainless Steel Reinforced PTFE: For Maximum Heat

For the most demanding high-temperature applications, PTFE interwoven with stainless steel provides the widest operating range, capable of withstanding temperatures up to 288°C (550°F).

Understanding the Trade-offs

Temperature is a primary consideration, but it must be evaluated alongside other operational factors for a successful outcome.

The Combined Effect of Temperature and Pressure

A packing's ability to withstand pressure is inversely related to its operating temperature. As temperatures rise, the maximum pressure the packing can handle decreases. Always consult manufacturer charts for the specific pressure-temperature (PV) limits of any material.

Chemical Compatibility Is Also Critical

While PTFE is resistant to most chemicals, certain aggressive substances at high temperatures may require specialized packing, such as PTFE with graphite. Always verify that your chosen packing is compatible with the specific media being sealed.

Making the Right Choice for Your Application

Use your application's full temperature range as the primary filter for selecting the right material.

- If your primary focus is general industrial use: Standard PTFE packing is often the most cost-effective and reliable choice for applications within its broad -45°C to 204°C range.

- If your primary focus is moderate to high heat: Select a reinforced PTFE (RPTFE) or carbon-filled variant to gain an extra margin of safety against softening.

- If your primary focus is extreme heat or pressure: Stainless steel reinforced PTFE is engineered specifically to maintain integrity in the most demanding environments.

- If your primary focus is cryogenic service: The inherent low-temperature stability of pure PTFE makes it a superior choice over most elastomers or other plastics.

Ultimately, selecting the correct packing is a critical engineering decision that directly impacts the reliability and safety of your equipment.

Summary Table:

| PTFE Variant | Typical Temperature Range (°C) | Typical Temperature Range (°F) | Key Applications |

|---|---|---|---|

| Standard PTFE | -45°C to 204°C | -50°F to 400°F | General industrial use, cost-effective sealing |

| Reinforced PTFE (RPTFE) | Up to 232°C | Up to 450°F | Moderate to high heat applications |

| Stainless Steel PTFE | Up to 288°C | Up to 550°F | Extreme heat and pressure environments |

Ensure Unmatched Reliability with KINTEK PTFE Components

Selecting the correct PTFE packing is critical for the safety and efficiency of your equipment. KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your components perform flawlessly across your specific temperature and pressure requirements.

Don't let material failure compromise your operations. Contact our experts today to discuss your application needs and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Are expanded PTFE gaskets as durable as standard PTFE gaskets? Discover the Best Choice for Your Seal.

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What role does PTFE play in vibration dampening in piping systems? | Reduce Stress & Wear

- What are the advantages of PTFE rod over other materials? Superior Chemical & Thermal Performance

- What are the benefits of low friction in PTFE lined valves? Achieve Smoother Operation and Lower Costs

- What future trends are expected in the development of PTFE rotary shaft seals? From Passive Parts to Smart System Components

- What is unique about PTFE waffle seals and their applications? Superior Sealing with Built-In Contamination Control

- What makes PTFE-lined butterfly valves durable? Unmatched Chemical & Thermal Resistance