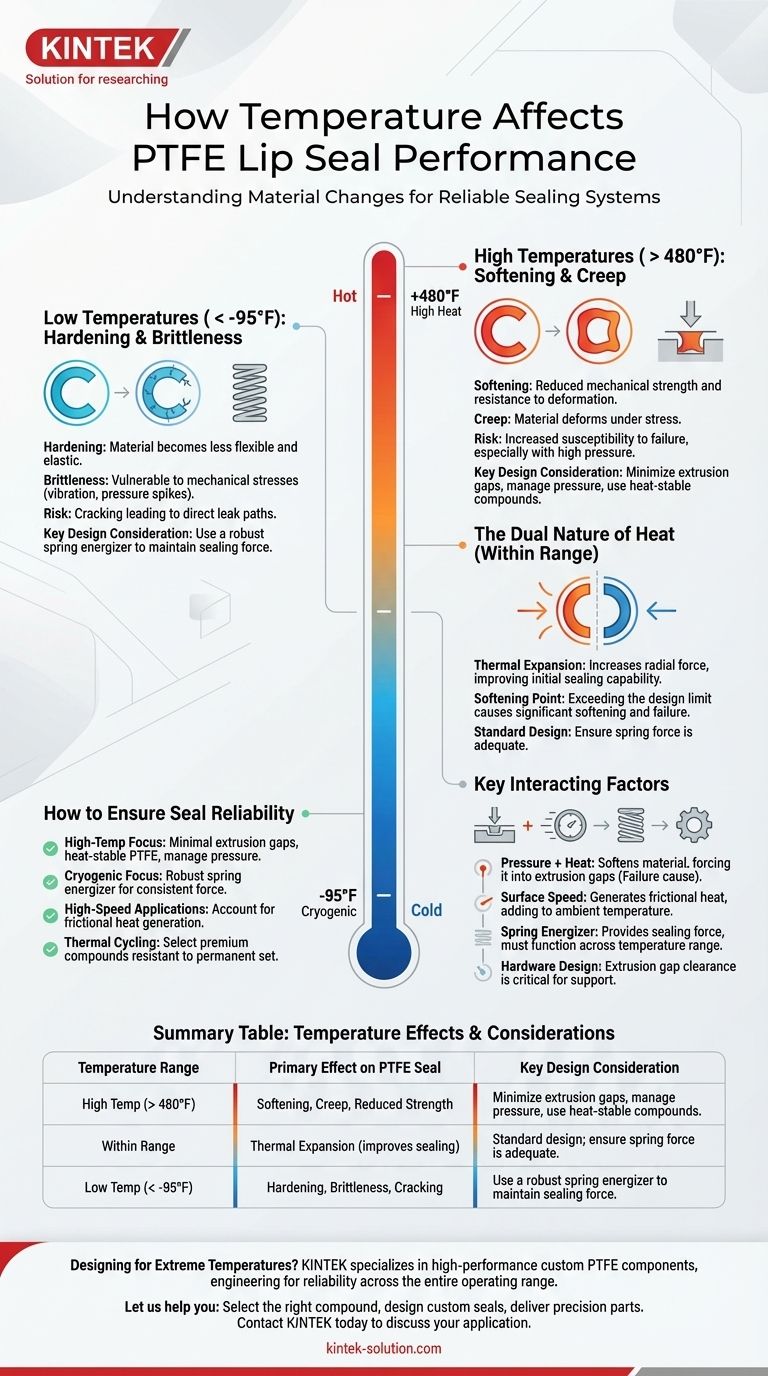

Temperature is a defining factor in the performance and reliability of any Polytetrafluoroethylene (PTFE) lip seal. It directly alters the physical properties of the seal material, with high temperatures causing softening that can reduce sealing effectiveness, and low temperatures causing hardening and brittleness that can lead to cracks. While PTFE boasts a wide functional range, typically from -95°F to 480°F, successful application depends on understanding these material changes.

The core challenge is not simply operating within a temperature range, but engineering the entire sealing system—hardware, pressure, and speed—to accommodate the predictable physical changes that PTFE undergoes at temperature extremes.

The Dual Nature of Heat on PTFE Seals

Heat's effect on a PTFE seal is not entirely negative. The outcome depends entirely on whether the temperature remains within the material's designed operating limits.

Thermal Expansion: A Sealing Advantage

When initially exposed to heat within its working range, a PTFE seal expands. This thermal expansion increases the radial force on the sealing lip, enhancing its contact with the shaft and improving the overall sealing capability against leaks.

The Softening Point: The Upper Limit

Once temperatures exceed the design limit, the PTFE material begins to soften significantly. This reduces its mechanical strength and resistance to deformation, a phenomenon known as "creep." A softened seal is far more susceptible to failure, especially when high system pressure is also present.

The Impact of Cryogenic Temperatures

At the low end of its operating range, PTFE undergoes a different transformation that presents its own set of challenges.

Increased Hardness and Brittleness

As temperatures drop, the PTFE polymer becomes progressively harder and less flexible. Its ability to conform to imperfections in the shaft surface is reduced, and its elasticity diminishes.

The Risk of Cracking

This loss of flexibility makes the seal brittle and vulnerable. Mechanical stresses, such as shaft vibration or sudden pressure spikes, can cause the hardened seal lip to develop cracks, creating a direct leak path.

Key Interacting Factors Beyond Temperature

Temperature is never an isolated variable in a dynamic sealing system. Its effects are magnified or mitigated by several other critical operating conditions.

The Compounding Effect of Pressure

The combination of high temperature and high pressure is the most common cause of seal failure. The heat softens the material, and the pressure then forces the weakened PTFE into the hardware's extrusion gap, causing irreversible damage.

Frictional Heat from Surface Speed

PTFE seals are excellent for high-speed applications, capable of handling surface speeds up to 10,000 feet per minute (sfpm). However, this speed generates significant frictional heat directly at the point of contact. This heat must be added to the system's ambient and media temperatures to determine the true operating temperature of the seal lip.

The Role of the Spring Energizer

The internal spring provides the initial sealing force, especially at low pressures and low temperatures when the PTFE jacket is stiff. The spring material must be chosen to function reliably across the entire temperature range without losing its mechanical properties.

Hardware Design and Clearance

The extrusion gap—the small clearance between the shaft and the housing—is a critical design factor. A precisely controlled, minimal gap provides support for the seal and prevents the softened PTFE material from being pushed out of place at high temperatures.

Common Pitfalls to Avoid

Understanding the limitations and potential failure modes is essential for reliable design.

Ignoring Thermal Cycling

Repeatedly cycling between hot and cold can cause the seal material to permanently deform, a condition known as permanent set. Over time, this reduces the seal's ability to exert force on the shaft, eventually leading to leakage.

Overlooking Frictional Heat

A common engineering mistake is to design based only on the system's ambient or media temperature. Failing to calculate and add the heat generated by friction at the seal interface can cause the seal to operate at a much higher temperature than intended, leading to premature failure.

Mismatched Materials

The PTFE jacket, spring energizer, and hardware must all be compatible with the application's temperature range. A low-temperature spring in a high-temperature application, for example, will lose its force and cause the seal to fail.

How to Ensure Seal Reliability Across Temperatures

Your design choices should be guided by the most extreme conditions your application will face.

- If your primary focus is high-temperature performance: Prioritize a design with minimal extrusion gaps and select a PTFE compound specifically engineered for heat stability, while carefully managing system pressure.

- If your primary focus is cryogenic performance: Ensure the spring energizer is robust enough to provide consistent sealing force when the PTFE jacket is hard and less flexible.

- If your application involves high speeds: Account for frictional heat generation in your total thermal calculations to avoid exceeding the material's upper temperature limit.

- If you face significant thermal cycling: Select a premium polymer compound and spring design known for their resistance to permanent set and material fatigue.

Properly accounting for temperature and its interactions with other system variables is the definitive step toward designing a robust and reliable sealing solution.

Summary Table:

| Temperature Range | Primary Effect on PTFE Seal | Key Design Consideration |

|---|---|---|

| High Temp (> 480°F) | Softening, Creep, Reduced Strength | Minimize extrusion gaps, manage pressure, use heat-stable compounds. |

| Within Range | Thermal Expansion (improves sealing) | Standard design; ensure spring force is adequate. |

| Low Temp (< -95°F) | Hardening, Brittleness, Cracking | Use a robust spring energizer to maintain sealing force. |

Designing a sealing solution for extreme temperatures?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical interplay of temperature, pressure, and speed, and we engineer our seals for maximum reliability across your entire operating range.

Let us help you:

- Select the right PTFE compound for your specific temperature profile.

- Design custom seals that account for frictional heat and thermal cycling.

- Deliver precision parts from prototypes to high-volume production.

Contact KINTEK today to discuss your application and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts