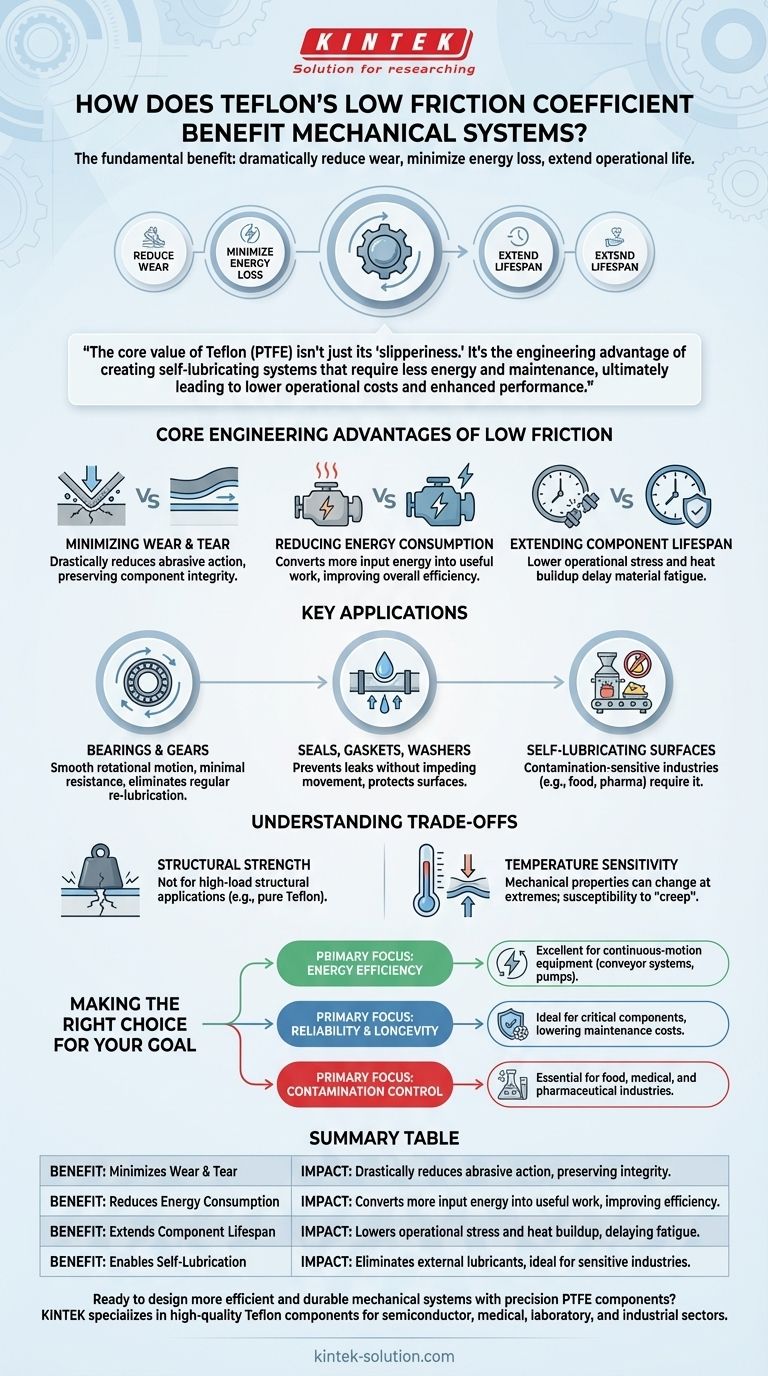

The fundamental benefit of Teflon's low friction coefficient in mechanical systems is its ability to dramatically reduce wear, minimize energy loss, and extend the operational life of moving components. By allowing parts to slide against each other with minimal resistance, it creates more efficient, reliable, and durable machinery.

The core value of Teflon (PTFE) isn't just its "slipperiness." It's the engineering advantage of creating self-lubricating systems that require less energy and maintenance, ultimately leading to lower operational costs and enhanced performance.

The Core Engineering Advantages of Low Friction

Teflon's defining characteristic is its extremely low coefficient of friction, typically between 0.05 and 0.15. This property translates directly into tangible benefits for any system with moving parts.

Minimizing Wear and Tear

Friction is the primary cause of mechanical wear. When components rub against each other, material is slowly abraded away, degrading performance and leading to eventual failure.

Teflon’s low-friction surface allows parts to glide smoothly, drastically reducing this abrasive action and preserving the integrity of the components for longer.

Reducing Energy Consumption

In any mechanical system, friction represents wasted energy, which is lost as heat. Overcoming this resistance requires more power from the motor or engine.

By minimizing friction, Teflon coatings and components ensure that more of the input energy is converted into useful work, improving the overall efficiency of the equipment.

Extending Component Lifespan

The combined effects of reduced wear and lower operational stress directly contribute to a longer service life.

Components in contact with Teflon last longer because they are subjected to less physical degradation and heat buildup, which delays material fatigue and failure.

Key Applications in Mechanical Systems

The self-lubricating nature of Teflon makes it indispensable in applications where traditional lubricants are impractical or undesirable.

Bearings and Gears

In bearings and gears, smooth rotational motion is critical. Teflon coatings or solid Teflon parts allow these components to operate with minimal resistance.

This is especially valuable in systems where maintenance access is difficult, as the need for regular re-lubrication is eliminated.

Seals, Gaskets, and Washers

Sealing components must prevent leaks without impeding the movement of parts like valve stems or pump shafts.

Teflon's low friction allows it to create a tight seal while still permitting smooth movement, preventing the seal from wearing out the very part it is designed to protect.

Self-Lubricating Surfaces

Many industries, such as food processing and pharmaceuticals, cannot risk product contamination from grease or oil.

Teflon provides a self-lubricating solution, ensuring machinery runs smoothly without introducing external lubricants into a sensitive environment.

Understanding the Trade-offs

While its low friction is a significant advantage, Teflon is not a universal solution. An objective assessment requires acknowledging its limitations.

Structural Strength

Pure Teflon is a relatively soft material. It is not suitable for high-load structural applications where materials like steel or reinforced composites are required to bear significant weight or impact.

Temperature Sensitivity

While Teflon has a wide operating temperature range, its mechanical properties can change at extremes. It can also be susceptible to "creep," a slow deformation that occurs under sustained pressure over time, which must be accounted for in component design.

Making the Right Choice for Your Goal

Selecting the right material is about aligning its properties with your primary objective.

- If your primary focus is energy efficiency: Teflon is an excellent choice for minimizing frictional losses in continuous-motion equipment like conveyor systems and pumps.

- If your primary focus is reliability and longevity: Its ability to drastically reduce wear makes it ideal for extending the life of critical components like bearings and seals, lowering maintenance costs.

- If your primary focus is contamination control: Teflon's self-lubricating properties are essential for applications in the food, medical, and pharmaceutical industries.

Ultimately, leveraging Teflon's low friction coefficient allows engineers to design systems that are not just functional, but fundamentally more efficient and durable.

Summary Table:

| Benefit | Impact on Mechanical Systems |

|---|---|

| Minimizes Wear & Tear | Drastically reduces abrasive action, preserving component integrity. |

| Reduces Energy Consumption | Converts more input energy into useful work, improving efficiency. |

| Extends Component Lifespan | Lowers operational stress and heat buildup, delaying material fatigue. |

| Enables Self-Lubrication | Eliminates need for external lubricants, ideal for contamination-sensitive industries. |

Ready to design more efficient and durable mechanical systems with precision PTFE components?

At KINTEK, we specialize in manufacturing high-quality Teflon (PTFE) components—including seals, liners, bearings, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the exact low-friction solution your application demands.

Contact us today to discuss how our PTFE components can reduce your maintenance costs, improve reliability, and enhance the performance of your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What specific advantages do PTFE coated bolts and screws offer? Achieve Reliable, Seizure-Free Assemblies

- Why is PTFE's low friction property beneficial in manufacturing? To Reduce Wear, Downtime & Energy Costs

- What role does Teflon sheet play in the packaging industry? Ensuring Clean, Non-Stick Heat Sealing

- What are the common product forms of Teflon? A Guide to PTFE Sheets, Tapes, Coatings & More

- How does CAD/CAM software enhance the precision of CNC machined PTFE parts? Master Digital Machining for Flawless Components

- What types of devices are Teflon bellow mechanical seals used in? A Guide for Extreme Conditions

- Why are PTFE bearings preferred in chemical processing equipment? Unmatched Chemical Inertness for Reliability

- What advantages do PTFE rotary shaft seals offer in high-speed applications? Unlock Superior Speed and Reliability