In short, Teflon performs exceptionally well in outdoor applications. Its unique chemical structure provides outstanding resistance to the primary factors that degrade materials outdoors, including UV radiation, extreme temperature fluctuations, and moisture. This makes it one of the most durable and reliable polymers for harsh environmental exposure.

The core reason for Teflon's success outdoors is its extreme chemical inertness. The powerful carbon-fluorine bonds that make it non-reactive also make it nearly immune to UV degradation, weathering, and moisture, ensuring long-term stability and performance.

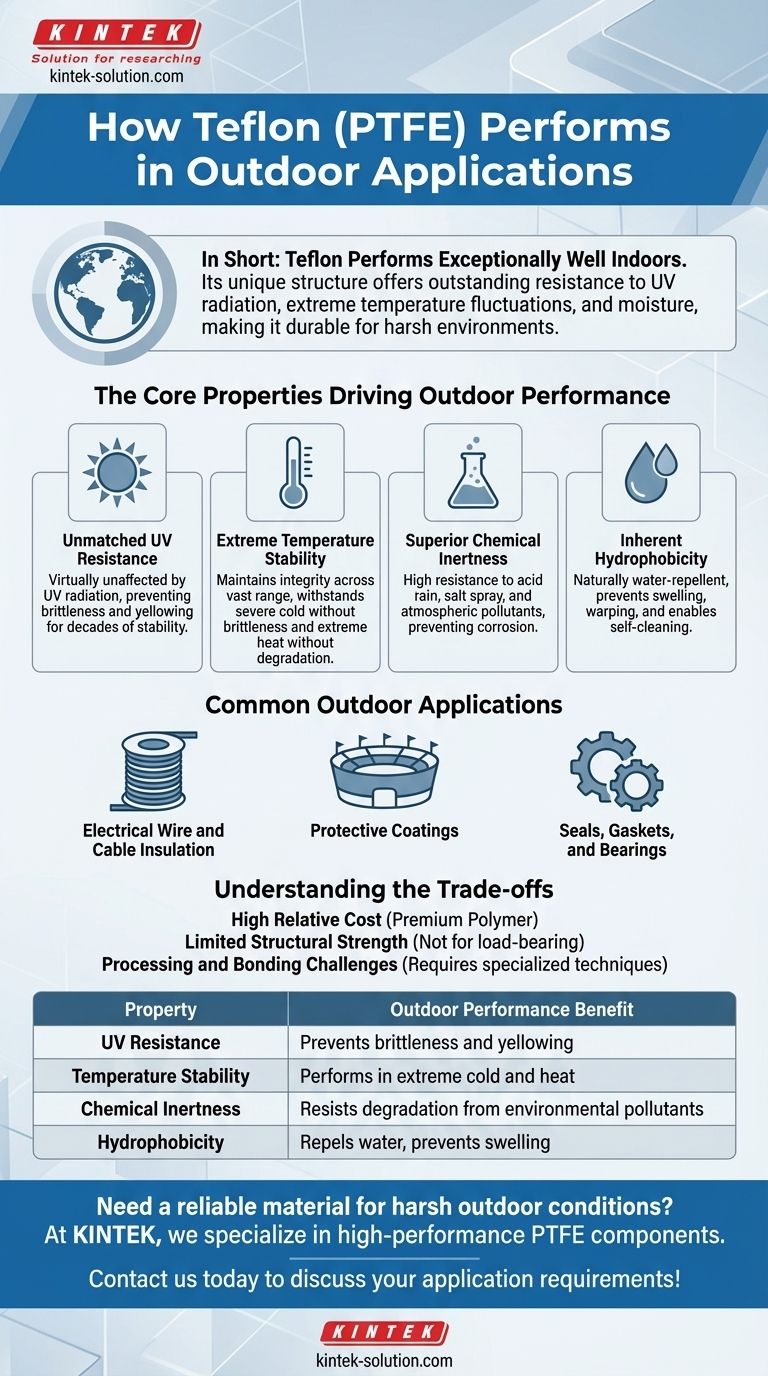

The Core Properties Driving Outdoor Performance

To understand why Teflon (PTFE) excels outdoors, we need to examine its fundamental material properties. These characteristics work together to create a robust barrier against environmental stress.

Unmatched UV Resistance

Unlike many plastics that become brittle and yellow with sun exposure, Teflon is virtually unaffected by UV radiation. Its chemical bonds are too strong to be broken down by solar energy, ensuring it retains its mechanical properties and color over decades.

Extreme Temperature Stability

Teflon maintains its integrity across a vast temperature range. It can withstand severe cold without becoming brittle and extreme heat without degrading, making it suitable for climates from the arctic to the desert.

Superior Chemical Inertness

This material is famous for being non-reactive. In an outdoor setting, this translates to high resistance against acid rain, salt spray (in coastal areas), and atmospheric pollutants, which can corrode or weaken other materials.

Inherent Hydrophobicity

Teflon is naturally water-repellent, a property known as hydrophobicity. It does not absorb moisture, which prevents swelling, warping, or degradation from rain, snow, and humidity. This also gives it a self-cleaning quality, as water beads up and rolls off, taking dirt with it.

Common Outdoor Applications

Teflon's robust properties make it the material of choice for demanding applications where failure is not an option.

Electrical Wire and Cable Insulation

This is a primary outdoor use. Teflon's excellent dielectric properties combined with its weather resistance make it ideal for insulating critical wiring that is exposed to the elements, ensuring signal integrity and safety.

Protective Coatings

Teflon is often used as a coating for fabrics in architectural membranes (like stadium roofs) or as a protective layer on metal components. It provides a weatherproof, low-friction, and chemically resistant surface.

Seals, Gaskets, and Bearings

In outdoor machinery or equipment, Teflon is used for seals and gaskets that must perform reliably despite exposure to moisture and temperature swings. Its low-friction nature is an added benefit for moving parts.

Understanding the Trade-offs

While its performance is exceptional, Teflon is not the solution for every problem. Its unique properties come with practical limitations that must be considered during material selection.

High Relative Cost

Teflon is a premium performance polymer, and its cost is significantly higher than common plastics like polyethylene or PVC. Its use is typically justified by the need for extreme durability and long service life.

Limited Structural Strength

Teflon is a relatively soft material with low tensile strength compared to engineering plastics. It is not suitable for load-bearing structural applications and can be susceptible to "creep" or deformation under sustained pressure.

Processing and Bonding Challenges

Due to its chemical inertness and low-friction surface, Teflon is very difficult to bond to other materials using conventional adhesives. It also requires specialized techniques for molding and machining.

Making the Right Choice for Your Application

Selecting Teflon depends entirely on balancing performance requirements against practical constraints.

- If your primary focus is maximum durability and chemical/UV resistance: Teflon is a top-tier choice where long-term, maintenance-free performance is the most critical factor and budget is secondary.

- If your primary focus is electrical insulation in a harsh environment: Teflon's combination of high dielectric strength and world-class weatherability is nearly unmatched for critical outdoor wiring.

- If your primary focus is a structural or high-strength component: You should consider other engineering polymers, as Teflon lacks the rigidity and mechanical strength for load-bearing roles.

Ultimately, Teflon is a specialized material chosen for its ability to perform reliably where most other plastics would fail.

Summary Table:

| Property | Outdoor Performance Benefit |

|---|---|

| UV Resistance | Prevents brittleness and yellowing, ensuring decades of stability. |

| Temperature Stability | Performs in extreme cold and heat, from arctic to desert climates. |

| Chemical Inertness | Resists degradation from acid rain, salt spray, and pollutants. |

| Hydrophobicity | Repels water to prevent swelling, warping, and enables self-cleaning. |

Need a reliable material for harsh outdoor conditions?

At KINTEK, we specialize in manufacturing high-performance PTFE components like seals, liners, and labware. Our expertise ensures precision production and custom fabrication—from prototypes to high-volume orders—for industries like semiconductor, medical, laboratory, and industrial sectors.

Let us provide you with durable PTFE solutions that withstand UV radiation, extreme temperatures, and moisture. Contact us today to discuss your specific application requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- When did the industrial production of PTFE begin? From Military Secret to Industrial Revolution

- How is Teflon utilized in the electronics industry? Ensuring Signal Integrity and Reliability

- What are the key properties of PTFE that make it ideal for industrial use? Unlock Unmatched Performance in Harsh Environments

- What is PTFE and how was it discovered? The Accidental Invention of Teflon

- What makes PTFE chemically resistant and why is this advantageous? Achieve Unmatched Reliability in Harsh Environments

- What are some common uses of PTFE laminated fabrics? Essential for Waterproof, Breathable Performance Gear

- What are the advantages of PTFE in terms of shelf life and service intervals? Maximize Reliability and Minimize Downtime

- What are the benefits of PTFE's chemical resistance? Achieve Unmatched Reliability in Corrosive Environments