In mechanical systems, PTFE's exceptionally low coefficient of friction is a foundational advantage that directly translates into reduced wear on moving parts, lower energy consumption, and a significantly extended equipment lifespan. This inherent "slipperiness" allows components to slide against each other with minimal resistance, creating a self-lubricating effect that is critical in demanding industrial environments.

PTFE’s value isn't just that it's "non-stick." Its low friction is a core engineering property that solves fundamental mechanical challenges, boosting system efficiency and reliability, especially in applications where traditional liquid lubricants are impractical or undesirable.

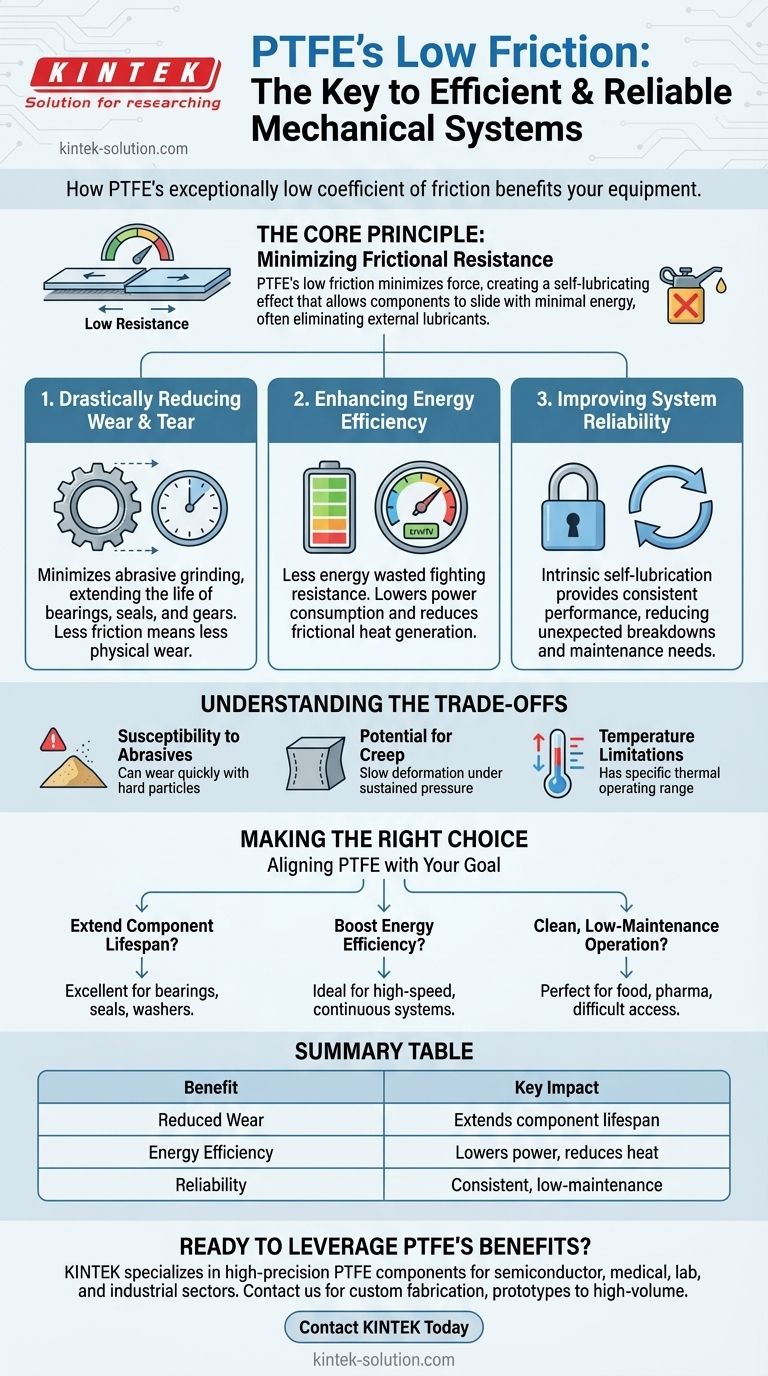

The Core Principle: Minimizing Frictional Resistance

At its heart, the benefit of PTFE (polytetrafluoroethylene), often known by the brand name Teflon, is its ability to minimize the force that resists motion between two surfaces in contact.

What "Low Coefficient of Friction" Means

The coefficient of friction is a simple measure of how much force is required to slide one surface over another. PTFE has one of the lowest coefficients of any solid material.

This means that parts made from or coated with PTFE require very little energy to move against each other, which has profound implications for a machine's design and performance.

The Self-Lubricating Advantage

Because its friction is so low, PTFE often eliminates the need for external lubricants like oil or grease. This self-lubricating property is a game-changer.

It prevents contamination in sensitive industries like food processing and pharmaceuticals and drastically reduces maintenance needs for machinery where access is difficult or costly.

The Three Pillars of PTFE's Mechanical Benefit

The single property of low friction delivers three distinct, high-impact benefits in any mechanical system.

Pillar 1: Drastically Reducing Wear and Tear

Friction is the primary driver of wear in moving components. By minimizing this force, PTFE directly extends the life of parts.

Components like bearings, gears, and O-rings that slide or rub against each other last longer because the abrasive, grinding effect of friction is all but removed. This leads to a longer service life for the entire machine.

Pillar 2: Enhancing Energy Efficiency

Every bit of energy used to overcome friction is wasted energy, often lost as heat. In high-speed systems with components like impellers or dynamic seals, this energy loss can be substantial.

PTFE's low friction means less energy is wasted fighting resistance. This improves overall system efficiency and can result in significant power savings over the equipment's operational lifetime. It also reduces frictional heating, which can protect sensitive components.

Pillar 3: Improving System Reliability

Systems that rely on external lubricants have an inherent failure point: the lubricant can run out, degrade, or fail to reach the necessary area.

Because PTFE's lubricating property is an intrinsic part of the material itself, it provides consistent, reliable performance. This reduces unexpected breakdowns and lowers the frequency of required maintenance.

Understanding the Trade-offs

While its low friction is a powerful benefit, PTFE is not the solution for every mechanical problem. Understanding its limitations is key to using it effectively.

Susceptibility to Abrasives

PTFE is a relatively soft material. In environments with hard, abrasive particles (like sand or metal filings), it can wear out quickly. The low-friction surface can be compromised by scratching and gouging.

Potential for Creep (Cold Flow)

Under sustained pressure, especially at elevated temperatures, PTFE can slowly deform or "creep." In high-load static sealing or bearing applications, this must be accounted for in the design to prevent failure.

Temperature Limitations

While PTFE has a wide operating temperature range, it has its limits. At very high temperatures, it can degrade, and at cryogenic temperatures, it can become less flexible. It is not suitable for applications that exceed its specified thermal limits.

Making the Right Choice for Your Goal

When deciding whether to leverage PTFE's low friction, consider your primary objective.

- If your primary focus is extending component lifespan: PTFE is an excellent choice for bearings, seals, and washers to minimize the physical wear caused by rubbing parts.

- If your primary focus is boosting energy efficiency: Use PTFE in high-speed or continuously operating dynamic systems to reduce energy loss and heat generation.

- If your primary focus is clean, low-maintenance operation: PTFE's self-lubricating nature makes it ideal for food, pharmaceutical, or difficult-to-access systems where external lubricants are a liability.

Ultimately, understanding PTFE's low friction allows you to design mechanical systems that are more efficient, durable, and reliable.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Reduced Wear | Extends component lifespan (bearings, seals, gears) |

| Energy Efficiency | Lowers power consumption and reduces frictional heat |

| Reliability | Self-lubricating for consistent, low-maintenance operation |

Ready to leverage PTFE's low friction in your mechanical systems?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment benefits from reduced wear, enhanced energy efficiency, and superior reliability.

Contact us today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What is a PTFE sliding rubber bearing pad and its primary use? Essential for Bridge & Building Movement

- How are PTFE tubes manufactured and what are their uses? A Guide to High-Performance Tubing Solutions

- What chemical resistance properties does PTFE bellow seal possess? Unmatched Protection Against Corrosive Media

- In what applications are PTFE balls highly functional? Ideal for Corrosive, Self-Lubricating Systems

- What are the key technical features of PTFE tri clamp gaskets? Unmatched Chemical & Thermal Resistance

- What are the benefits of graphite-filled PTFE? Superior Self-Lubrication for Demanding Seals & Bearings

- What are the advantages of a PTFE rotary lip seal not being spring-energized? Achieve Superior High-Speed Performance

- What colors are available for custom PTFE grades? Select the Right Color for Performance and Identification