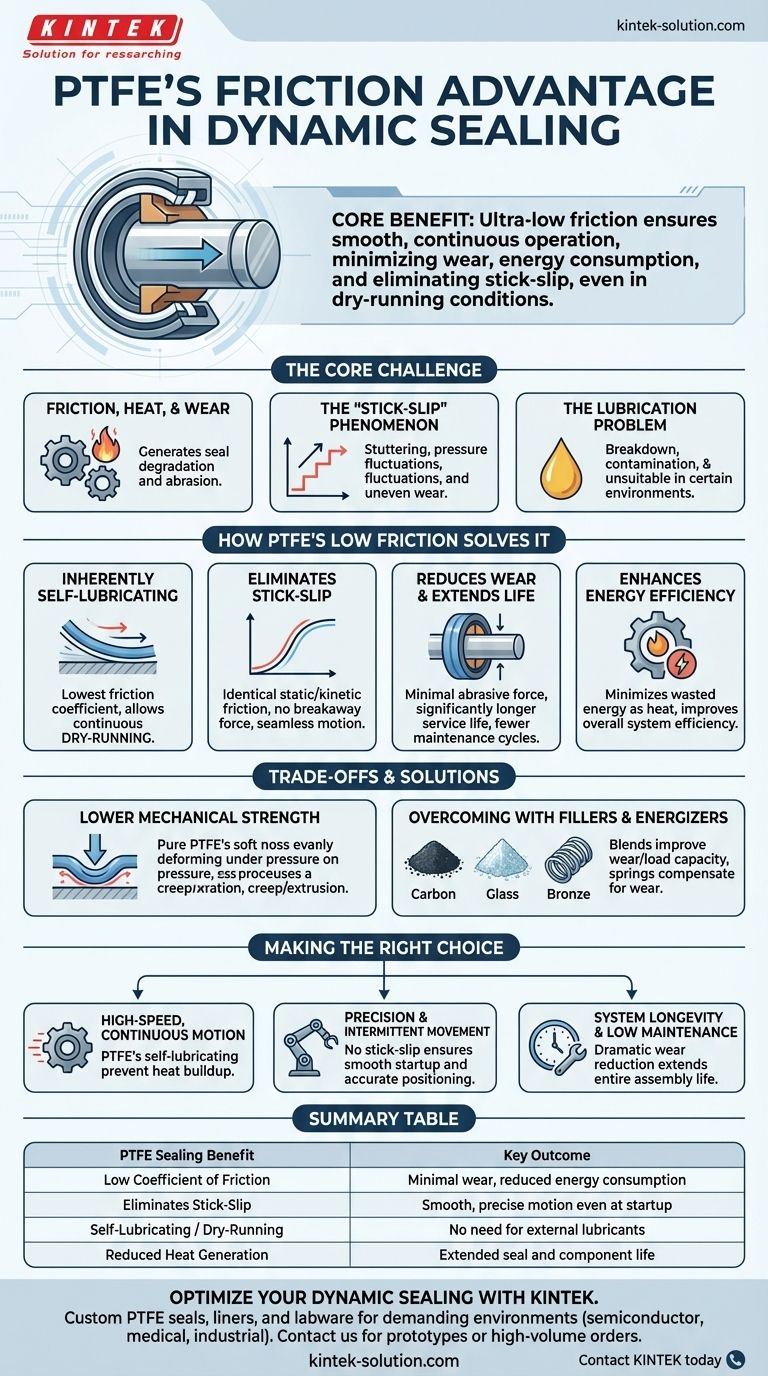

At its core, Polytetrafluoroethylene's (PTFE) extremely low coefficient of friction directly translates to superior performance and longevity in dynamic sealing applications. It minimizes wear, reduces energy consumption, and eliminates the destructive "stick-slip" phenomenon, allowing for smooth, continuous operation even without external lubrication.

In dynamic sealing, friction is the primary cause of failure, generating heat, wear, and inefficiency. PTFE's unique, self-lubricating nature fundamentally solves this problem, ensuring seal integrity and extending the operational life of the entire mechanical system.

The Core Challenge of Dynamic Sealing

In any system with moving parts, the seal is often the most critical and vulnerable component. The physics of motion introduces challenges that static seals do not face.

Friction, Heat, and Wear

When two surfaces move against each other, friction generates heat. This heat can cause the seal material to degrade, harden, or lose its shape, leading to leaks and eventual failure. The friction also physically abrades the seal and the mating surface, shortening the life of both components.

The "Stick-Slip" Phenomenon

"Stick-slip" describes the jerky motion that occurs when the force needed to start movement (static friction) is higher than the force needed to keep it moving (kinetic friction). In a dynamic seal, this causes stuttering, pressure fluctuations, and uneven wear, severely compromising performance and precision.

The Problem of Lubrication

Many traditional sealing materials require external lubrication to reduce friction. This introduces another variable—the lubricant can break down, become contaminated, or be unsuitable for the application environment (e.g., in food production or chemical processing).

How PTFE's Low Friction Solves These Problems

PTFE's properties offer a direct and elegant solution to the fundamental challenges of dynamic sealing. Its benefits are not additives; they are intrinsic to the material itself.

Inherently Self-Lubricating

PTFE has one of the lowest friction coefficients of any known solid. This allows surfaces to slide over it with almost no resistance. As a result, PTFE seals can operate in continuous dry-running conditions, completely eliminating the need for external lubrication.

Eliminating Stick-Slip

The static and kinetic coefficients of friction for PTFE are nearly identical. This means there is no "breakaway" force required to initiate movement. The transition from a complete stop to smooth motion is seamless, providing excellent stick-slip performance and enabling precise, predictable operation.

Reducing Wear and Extending Component Life

Because there is minimal abrasive force between the PTFE seal and the mating surface, wear and tear are drastically reduced. This leads to significantly longer service life, fewer maintenance cycles, and lower operational costs.

Enhancing Energy Efficiency

Friction is wasted energy. By minimizing it, PTFE seals ensure that nearly all applied force contributes to the intended mechanical work rather than being lost as heat. This reduction in frictional losses improves the overall energy efficiency of the system.

Understanding the Trade-offs

While its low friction is a massive advantage, it's important to understand the complete material profile of PTFE to use it effectively.

Lower Mechanical Strength

Pure, or "virgin," PTFE is a relatively soft material. Under high pressure or load, it can be susceptible to creep (slow deformation) or extrusion. This can be a limitation in high-pressure sealing applications.

The Role of Fillers and Energizers

To overcome these mechanical limitations, PTFE is often blended with fillers like carbon, glass, or bronze. These additives significantly improve wear resistance, load-bearing capacity, and dimensional stability while largely preserving the low-friction characteristic. In many seal designs, a metal spring is also used to "energize" the seal, providing a constant seating force to compensate for wear and pressure changes.

Making the Right Choice for Your Goal

Leveraging PTFE's properties effectively depends on understanding the primary demand of your application.

- If your primary focus is high-speed, continuous motion: PTFE's self-lubricating nature is critical for preventing heat buildup and enabling reliable dry-running performance.

- If your primary focus is precision and intermittent movement: The elimination of stick-slip behavior ensures smooth startup and accurate positioning without damaging, jerky motion.

- If your primary focus is system longevity and low maintenance: PTFE's ability to dramatically reduce wear on both the seal and mating hardware extends the life of the entire assembly.

By understanding and applying the principle of low friction, you can design dynamic systems that are more efficient, reliable, and durable.

Summary Table:

| PTFE Sealing Benefit | Key Outcome |

|---|---|

| Low Coefficient of Friction | Minimal wear, reduced energy consumption |

| Eliminates Stick-Slip | Smooth, precise motion even at startup |

| Self-Lubricating / Dry-Running | No need for external lubricants |

| Reduced Heat Generation | Extended seal and component life |

Ready to optimize your dynamic sealing applications with high-performance PTFE components?

At KINTEK, we specialize in the precision manufacturing of custom PTFE seals, liners, and labware. Our expertise ensures your systems benefit from reduced friction, extended service life, and reliable dry-running operation—perfect for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors.

Whether you need prototypes or high-volume orders, we deliver solutions tailored to your specific performance goals.

Contact KINTEK today to discuss your project and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts