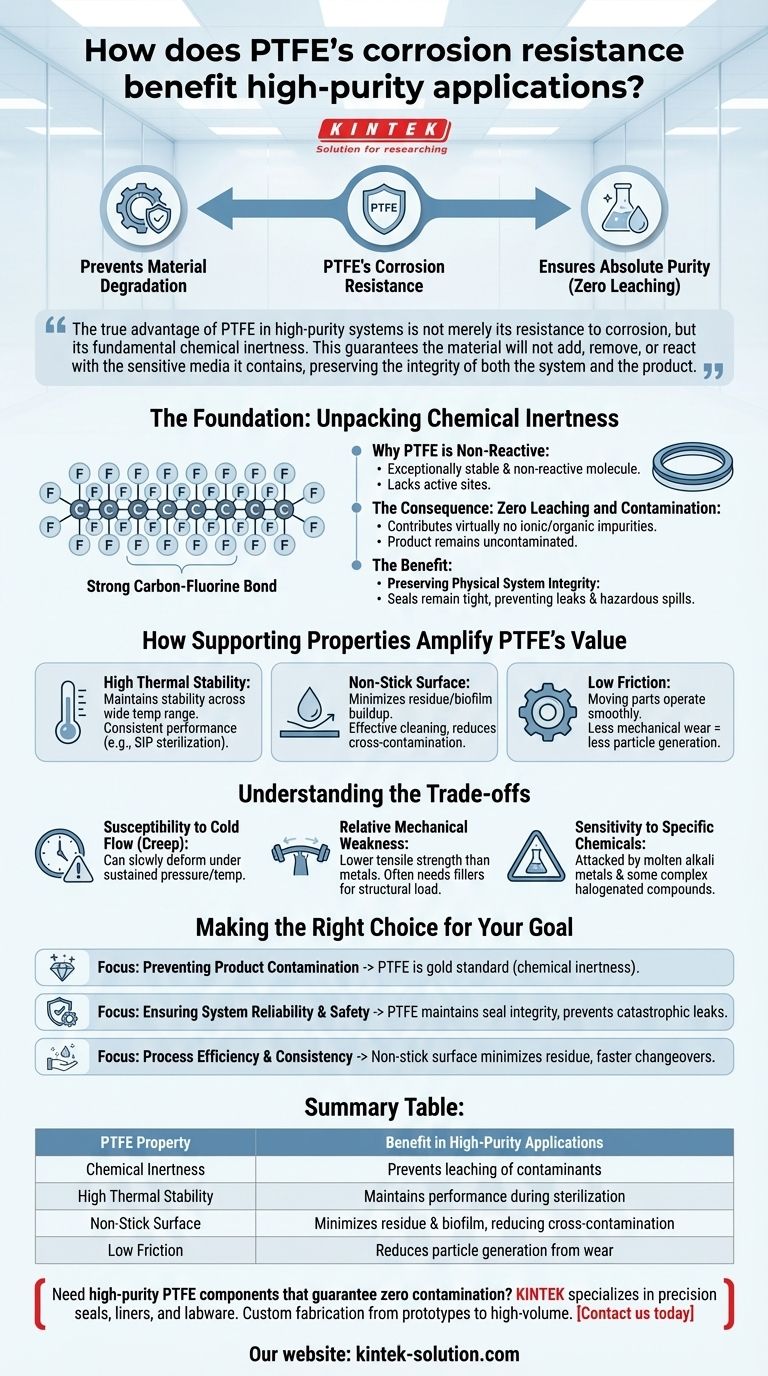

In high-purity applications, PTFE's corrosion resistance provides a dual benefit that is critical for success. It not only prevents the material itself from degrading when exposed to aggressive chemicals but, more importantly, it ensures the absolute purity of the process media by not leaching contaminants into the system. This chemical inertness is the foundation of its value in sensitive environments.

The true advantage of PTFE in high-purity systems is not merely its resistance to corrosion, but its fundamental chemical inertness. This guarantees the material will not add, remove, or react with the sensitive media it contains, preserving the integrity of both the system and the product.

The Foundation: Unpacking Chemical Inertness

High-purity applications in fields like semiconductors, pharmaceuticals, and biotechnology demand materials that do not interfere with the process. PTFE's unique molecular structure makes it exceptionally suited for this role.

Why PTFE is Non-Reactive

PTFE consists of a long chain of carbon atoms completely shielded by a layer of fluorine atoms. The carbon-fluorine bond is one of the strongest in organic chemistry.

This powerful bond makes the molecule exceptionally stable and non-reactive. It lacks the active sites that other materials have, which could react with acids, solvents, or other aggressive chemicals.

The Consequence: Zero Leaching and Contamination

In a high-purity system, the primary concern is contamination from leachables and extractables—trace chemicals that migrate from component materials into the process fluid.

Because PTFE is so inert, it simply does not break down or react when in contact with chemicals. This means it contributes virtually no ionic or organic impurities to the high-purity media, ensuring the product remains uncontaminated.

The Benefit: Preserving Physical System Integrity

Corrosion is not just a chemical problem; it is a physical one. When a material corrodes, it weakens.

For components like gaskets, seals, and O-rings, this is catastrophic. PTFE's ability to resist degradation ensures that seals remain tight, preventing leaks that could compromise a sterile environment or cause a hazardous spill. This reliability is non-negotiable in critical systems.

How Supporting Properties Amplify PTFE's Value

While chemical inertness is the primary driver, other inherent properties of PTFE work in concert to make it a superior choice for demanding applications.

High Thermal Stability

Many high-purity processes, such as steam-in-place (SIP) sterilization or certain chemical reactions, occur at elevated temperatures.

PTFE has a high melting point and maintains its stability across a wide temperature range. This means its chemical inertness is not compromised by thermal cycling, ensuring consistent performance.

Non-Stick Surface

PTFE's famous non-stick, or hydrophobic, surface is a significant advantage in high-purity fluid handling.

This property minimizes residue and biofilm buildup on tubing and vessel walls. This makes cleaning cycles more effective and dramatically reduces the risk of cross-contamination between different batches.

Low Friction

The low coefficient of friction means moving parts made from PTFE, such as bearings or valve seats, operate smoothly with minimal wear.

Less mechanical wear translates directly to less particle generation. In a semiconductor fab or pharmaceutical line, minimizing particulate contamination is just as important as preventing chemical leaching.

Understanding the Trade-offs

No material is perfect. While PTFE's properties are exceptional, it's crucial to be aware of its limitations to make informed engineering decisions.

Susceptibility to Cold Flow (Creep)

Under sustained pressure and temperature, PTFE can slowly deform, a phenomenon known as creep or "cold flow."

This can be a challenge for sealing applications, as a gasket might lose its sealing pressure over time. Modified or filled grades of PTFE are often used to mitigate this effect.

Relative Mechanical Weakness

Compared to metals or other high-performance polymers, virgin PTFE is relatively soft and has lower tensile strength.

It is not typically used for high-load structural components unless it is reinforced with fillers like glass fiber or carbon, which can in turn affect its purity profile.

Sensitivity to Specific Chemicals

While resistant to nearly everything, PTFE can be attacked by a few rare substances, such as molten alkali metals and some complex halogenated compounds at high temperatures and pressures. Always verify compatibility in extreme or unusual use cases.

Making the Right Choice for Your Goal

Selecting PTFE is about aligning its specific strengths with your primary engineering objective.

- If your primary focus is preventing product contamination: PTFE is the gold standard because its chemical inertness prevents the leaching of impurities into your sensitive media.

- If your primary focus is ensuring system reliability and safety: PTFE's ability to maintain seal integrity in gaskets and O-rings, even with aggressive chemicals, prevents catastrophic leaks and equipment failure.

- If your primary focus is process efficiency and consistency: The non-stick surface of PTFE minimizes residue, allowing for easier cleaning, faster changeovers, and a reduced risk of cross-contamination between batches.

By understanding these interconnected properties, you can confidently leverage PTFE to build robust and reliable high-purity systems.

Summary Table:

| PTFE Property | Benefit in High-Purity Applications |

|---|---|

| Chemical Inertness | Prevents leaching of contaminants into process media |

| High Thermal Stability | Maintains performance during sterilization and high-temp processes |

| Non-Stick Surface | Minimizes residue and biofilm buildup, reducing cross-contamination |

| Low Friction | Reduces particle generation from mechanical wear |

Need high-purity PTFE components that guarantee zero contamination? KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, and laboratory industries. Our custom fabrication services—from prototypes to high-volume orders—ensure your systems maintain absolute integrity. Contact us today to discuss your specific requirements and learn how our PTFE solutions can protect your critical processes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

- Custom PTFE Teflon Parts Manufacturer PTFE Cleaning Rack

- Custom PTFE Microwave Digestion Vessels for Demanding Applications

People Also Ask

- How was PTFE accidentally discovered? The Serendipitous Story of Teflon's Invention

- What are the limitations of PTFE in its applications? Understanding Its Mechanical Weaknesses

- What are the properties and applications of carbon-filled PTFE? Enhance Performance in Demanding Environments

- What factors can cause variations in the actual properties of PTFE? Don't Rely on Generic Data Sheets

- Why is PTFE considered versatile? A Material That Excels in Chemical, Thermal, and Frictional Resistance

- What is the chemical formula and CAS number for PTFE? Unlocking Its Unique Properties

- How is Teflon used in electronics? As a High-Performance Insulator and Semiconductor Component

- What are the physical properties of Teflon? Unlocking PTFE's Non-Stick, Heat-Resistant Power