In almost all cases, PTFE demonstrates exceptional performance when exposed to hydraulic fluids and harsh environmental conditions. Its chemical structure makes it virtually inert to all common and aggressive hydraulic fluids, including phosphate esters. This material also exhibits remarkable resilience against a wide spectrum of environmental factors, from extreme temperatures to weathering and corrosive agents, ensuring unparalleled durability and longevity.

PTFE’s primary value lies in its world-class chemical and thermal stability. However, its effectiveness in any application is ultimately governed by its mechanical limitations, specifically its performance under combined pressure and velocity.

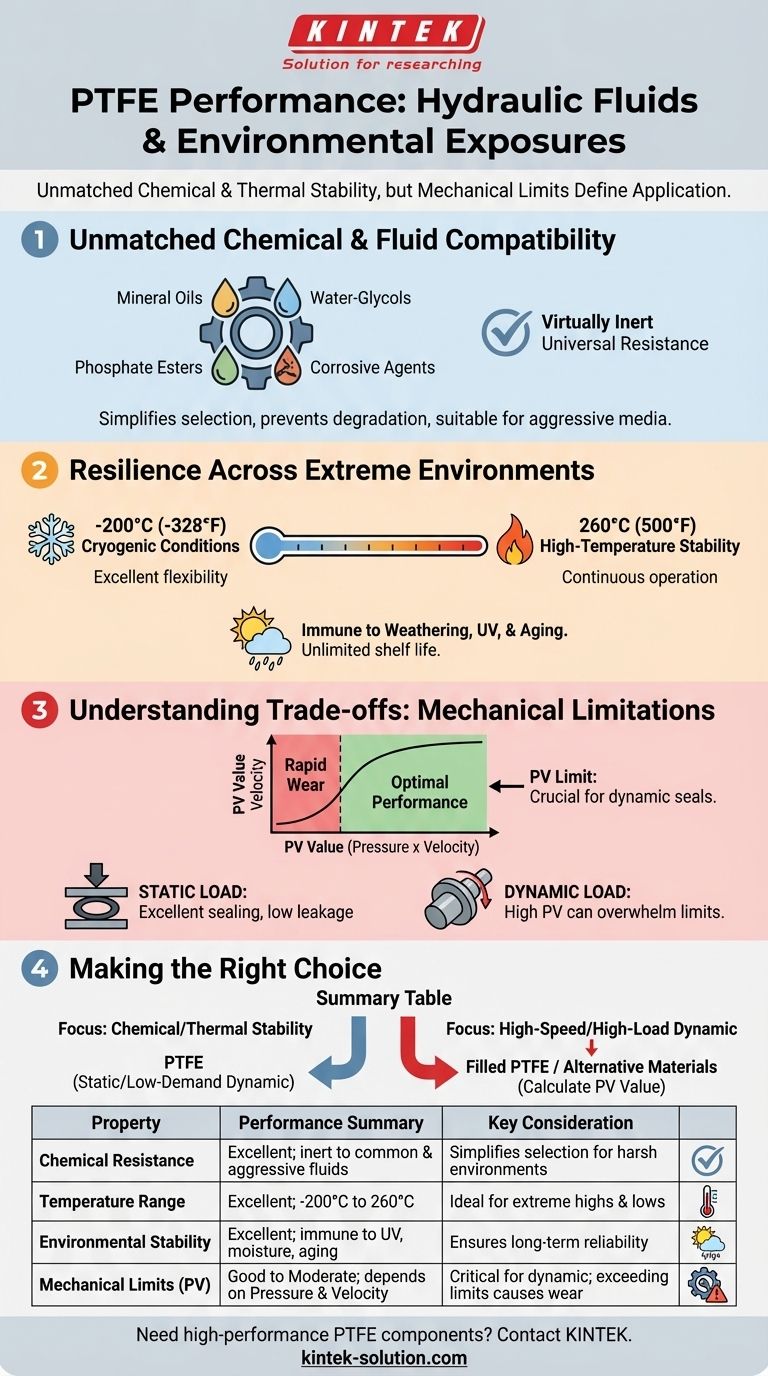

Unmatched Chemical & Fluid Compatibility

The molecular makeup of Polytetrafluoroethylene (PTFE) is the source of its legendary chemical resistance. This makes it a default choice for components that will face aggressive media.

Universal Resistance to Hydraulic Fluids

PTFE is chemically unaffected by virtually all types of hydraulic fluids. This includes mineral oils, water-glycols, and even chemically aggressive synthetic fluids like phosphate esters, which can degrade many other elastomers and plastics.

This universal compatibility simplifies material selection and ensures the integrity of components like seals and liners, preventing swelling, hardening, or chemical degradation.

Inertness to Corrosive Substances

Beyond hydraulic fluids, PTFE shows extreme resistance to a broad range of caustic and corrosive substances. This property makes it invaluable for applications in chemical processing, manufacturing, and other industries where components are exposed to harsh chemicals.

Resilience Across Extreme Environments

PTFE maintains its physical properties and structural integrity across an exceptionally wide range of environmental conditions, a key factor in its reliability and long service life.

Exceptional High-Temperature Stability

PTFE components can operate continuously at temperatures up to 260°C (500°F) without melting or degrading. This allows them to maintain sealing integrity and performance in high-temperature hydraulic systems, engines, and industrial machinery where other materials would fail.

Performance in Cryogenic Conditions

Just as it excels in heat, PTFE also demonstrates excellent performance at extremely cold temperatures. It remains flexible and functional in cryogenic applications down to approximately -200°C (-328°F), making it suitable for systems involving liquefied gases and other low-temperature processes.

Immunity to Weathering and Aging

PTFE is not affected by environmental factors like UV radiation (sunlight), moisture, oxygen, or ozone. As a result, PTFE components do not age or degrade over time, giving them a practically unlimited shelf life and ensuring long-term reliability in outdoor or exposed applications.

Understanding the Trade-offs: Mechanical Limitations

While its chemical and thermal properties are top-tier, PTFE is not without limitations. Its primary trade-offs are mechanical, and understanding them is critical for successful application design.

The Importance of Pressure and Velocity (PV)

The single most important factor governing the life of a dynamic PTFE seal is its PV value, which is the product of Pressure (P) and surface Velocity (V).

PTFE performs best under moderate loads and speeds. If the combined PV value exceeds the manufacturer's recommended limit for a specific PTFE grade, it can lead to rapid heat generation and premature wear.

Behavior Under Static vs. Dynamic Loads

In a static application like a gasket, PTFE's ability to maintain a seal under high pressure is excellent. It exhibits very low leakage rates with minimal surface compression.

However, in a dynamic application (e.g., a rotating shaft seal), the combination of high mechanical load and high speed can overwhelm its physical limits, even if the temperature and chemical environment are benign.

Making the Right Choice for Your Application

To leverage PTFE's strengths effectively, you must align your material choice with the primary demands of your system.

- If your primary focus is maximum chemical inertness and thermal stability: PTFE is an industry-leading choice that will provide unmatched reliability in static or low-demand dynamic systems.

- If your primary focus is performance in high-speed, high-load dynamic sealing: You must carefully calculate the PV value and consider specialized filled PTFE grades or alternative high-performance materials designed for such conditions.

Choosing the right material requires balancing its inherent properties against the specific challenges of your application, and with PTFE, its mechanical limits are the key consideration.

Summary Table:

| Property | Performance Summary | Key Consideration |

|---|---|---|

| Chemical Resistance | Excellent; inert to all common hydraulic fluids (mineral oils, phosphate esters) and corrosive substances. | Simplifies material selection for harsh chemical environments. |

| Temperature Range | Excellent; performs from -200°C (-328°F) to 260°C (500°F). | Ideal for extreme temperature applications, both high and low. |

| Environmental Stability | Excellent; immune to UV, moisture, ozone, and aging. | Ensures long-term reliability and unlimited shelf life. |

| Mechanical Limits (PV Value) | Good to Moderate; performance depends on the combination of pressure and velocity. | Critical for dynamic applications; exceeding limits causes rapid wear. |

Need high-performance PTFE components that meet your exact specifications?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you require standard parts or custom fabrication—from prototypes to high-volume orders—we ensure your components deliver optimal chemical resistance and thermal stability.

Contact our experts today to discuss how our PTFE solutions can enhance the durability and reliability of your hydraulic systems and equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What industries commonly use PTFE? Leverage Its Chemical Resistance, Low Friction & Electrical Insulation

- What is ePTFE and how is it produced? Unlock the Power of Microporous PTFE

- What are the advantages of PTFE's impact resistance? Ensure Unmatched Durability in Harsh Environments

- What does PTFE stand for and what is its composition? Unlocking the Power of a Two-Element Polymer

- What is PTFE and what are its basic properties? The Ultimate Guide to the High-Performance Polymer

- How can PTFE properties be enhanced? Improve Wear, Strength, and Creep Resistance with Fillers

- Is PTFE coating safe to use? A Guide to Safe Temperatures and Applications

- What are bronze bushings made of? Discover the Copper-Tin Alloy for Superior Performance