In short, Polytetrafluoroethylene (PTFE) performs exceptionally well in harsh weather conditions. Its inherent chemical structure makes it almost completely immune to degradation from temperature extremes, moisture, and environmental contaminants. This ensures that components made from PTFE maintain their critical properties and have a very long service life even when fully exposed to the elements.

The core reason for PTFE's resilience is its chemical inertness and stable molecular bonds. This gives it a near-universal resistance to all forms of weather-related degradation, making it a benchmark material for demanding outdoor and environmental applications.

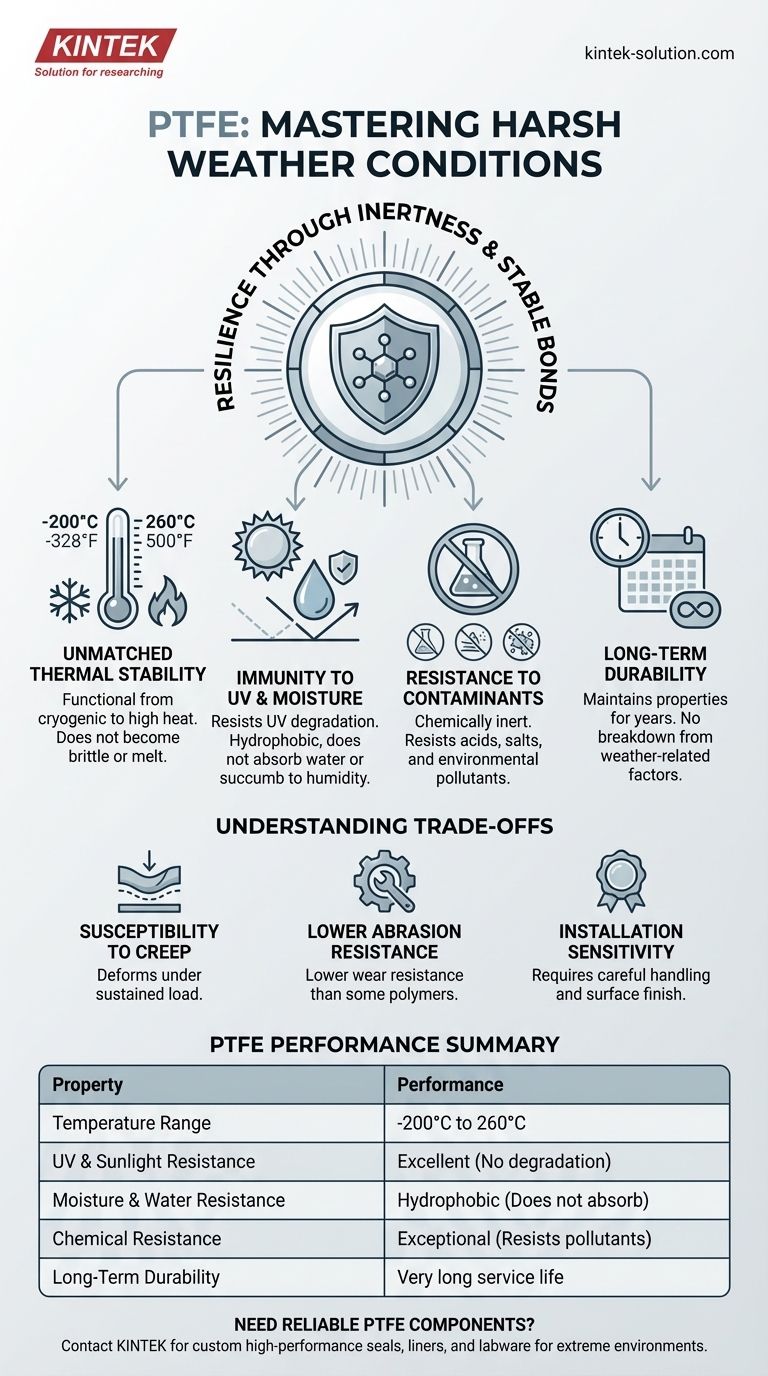

The Core Reasons for PTFE's Weather Resistance

To understand why PTFE is so reliable, we need to look at how it handles the specific factors that define "harsh weather."

Unmatched Thermal Stability

PTFE exhibits a remarkably wide operational temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This means it remains functional and stable in both cryogenic conditions and high-heat environments, from high-powered engines to the vacuum of space. It does not become brittle in the cold or melt in the heat within this range.

Immunity to UV Radiation and Moisture

The strong carbon-fluorine bonds in PTFE's molecular structure are not broken down by ultraviolet (UV) radiation from the sun.

Furthermore, PTFE is hydrophobic, meaning it repels water. It does not absorb moisture, so its properties are unaffected by rain, humidity, or snow.

Resistance to Environmental Contaminants

PTFE is one of the most chemically inert substances known.

This quality makes it resistant to damage from common environmental pollutants, acid rain, salt spray, and other corrosive chemicals it might encounter outdoors.

Long-Term Durability

Because of its resistance to thermal, UV, and chemical degradation, PTFE does not break down over time.

Components maintain their shape, flexibility, and performance for years without needing frequent replacement, giving the material a very long and predictable shelf life.

How This Translates to Real-World Performance

These inherent properties ensure that PTFE components function reliably in the most demanding situations.

Maintaining Seal Integrity

In applications like gaskets, O-rings, and seals, PTFE's stability is critical.

It continues to effectively seal mating surfaces without leaking, even when exposed to fluctuating temperatures and high pressures. It maintains its shape and compression, ensuring a consistent, long-term seal.

Reliability in Critical Environments

The use of PTFE in aerospace and aeronautical engineering underscores its exceptional reliability.

Its ability to perform flawlessly in the extreme temperatures and vacuum of space demonstrates a level of durability that far exceeds the demands of any terrestrial weather condition.

Understanding the Trade-offs

While its weather performance is outstanding, PTFE is not the solution for every problem. It's important to understand its limitations.

Susceptibility to Creep

PTFE is a relatively soft material and can be subject to "creep" or "cold flow." This means under a sustained mechanical load, it can slowly deform over time.

Lower Abrasion Resistance

Compared to other engineering polymers, PTFE has lower resistance to wear from friction and abrasion. For high-wear mechanical parts, filled grades of PTFE or other materials might be more suitable.

Installation Sensitivity

The softness of PTFE means that seals and gaskets can be easily damaged during installation if not handled carefully. Proper surface finish and installation procedures are critical to performance.

Making the Right Choice for Your Application

Ultimately, selecting PTFE depends on your primary engineering goal.

- If your primary focus is reliability across extreme temperatures: PTFE is an ideal choice due to its exceptionally wide and stable operating range.

- If your primary focus is long-term outdoor exposure: PTFE's inherent immunity to UV, moisture, and chemical contaminants makes it a leading candidate for a "set it and forget it" solution.

- If your primary focus is a high-load, abrasive mechanical part: You should evaluate filled grades of PTFE or alternative high-strength polymers to avoid issues with creep and wear.

PTFE stands as a first-class material for any application where unwavering performance against the elements is the primary concern.

Summary Table:

| Property | PTFE Performance in Harsh Weather |

|---|---|

| Temperature Range | -200°C to 260°C (-328°F to 500°F) |

| UV & Sunlight Resistance | Excellent (No degradation) |

| Moisture & Water Resistance | Hydrophobic (Does not absorb water) |

| Chemical Resistance | Exceptional (Resists acids, salts, pollutants) |

| Long-Term Durability | Very long service life with no breakdown |

Need a reliable PTFE component for your most demanding environments?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for industries where failure is not an option. Our expertise in precision production ensures your parts will deliver unwavering performance in extreme temperatures, corrosive conditions, and long-term outdoor exposure.

Whether you require prototypes or high-volume orders, we provide the material expertise and manufacturing excellence to meet your exact specifications.

Contact KINTEK today to discuss your application and receive a quote for a solution built to withstand the elements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main ingredients used in the production of PTFE? Unlocking its High-Performance Properties

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are some key facts about Teflon/PTFE? The Ultimate Guide to Its Unique Properties and Applications

- What is PTFE and what is its chemical composition? Unlocking the Power of the C-F Bond

- What modifications can be made to PTFE for enhanced performance? Boost Wear Resistance & Strength with Fillers

- How is PTFE laminated fabric used in shoe materials? Creating Waterproof & Breathable Footwear

- What makes ETFE Teflon suitable for aerospace applications? Lightweight & Durable for Harsh Environments

- What is modified PTFE and how does it differ from standard PTFE? A Guide to Enhanced Performance