In short, PTFE performs with exceptional reliability in chemically corrosive environments. Due to its unique molecular structure, it is one of the most chemically inert polymers known, making it a default choice for applications involving aggressive acids, bases, and solvents where other materials would quickly degrade.

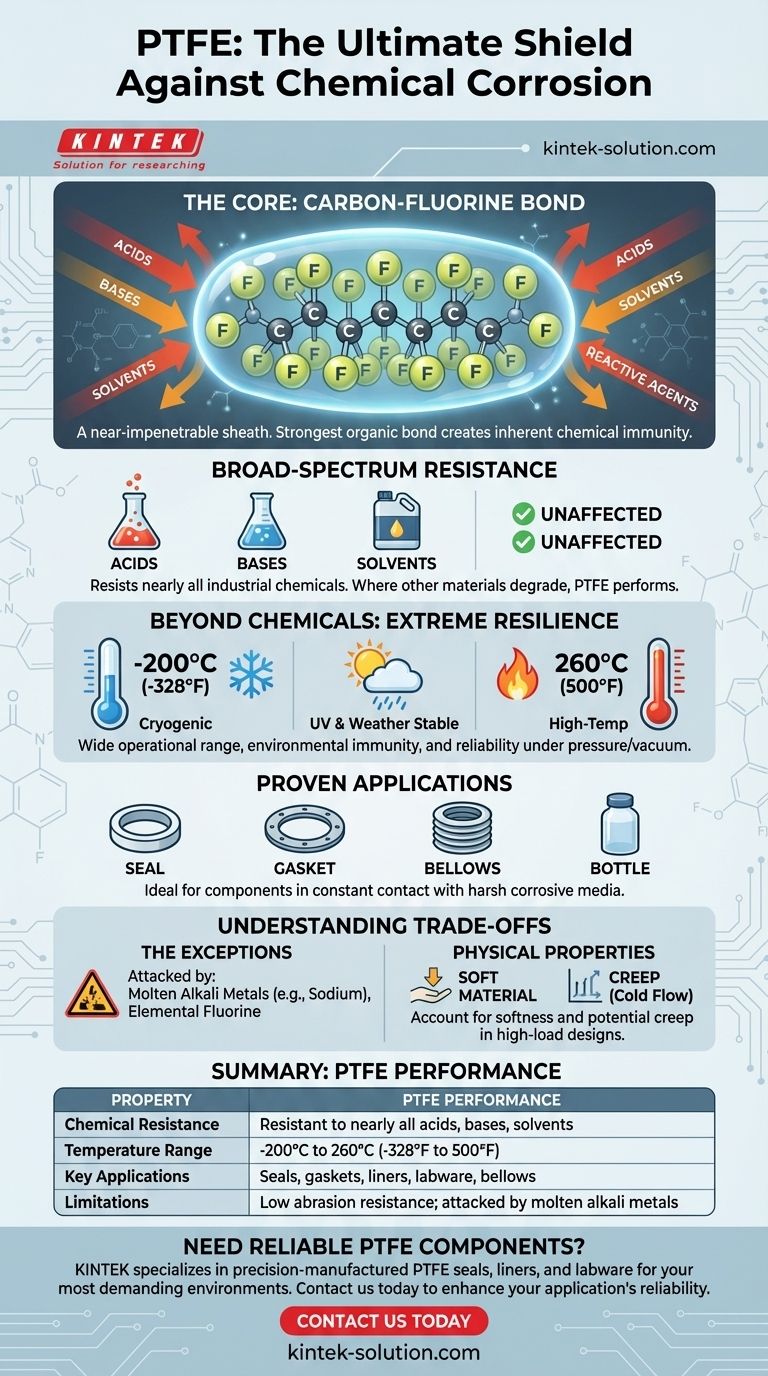

The core reason for PTFE's superior performance is its powerful carbon-fluorine bond, which creates a near-impenetrable shield against chemical attack. This inherent chemical immunity, combined with its tolerance for extreme temperatures, makes it a uniquely resilient material for the most demanding environments.

The Foundation of PTFE's Chemical Immunity

PTFE's reputation is built on its fundamental molecular stability. This stability is not a surface-level treatment but an intrinsic property of the material itself.

The Power of the Carbon-Fluorine Bond

At the heart of PTFE's performance is the carbon-fluorine (C-F) bond. This bond is one of the strongest known in organic chemistry.

The fluorine atoms effectively form a tight, stable, and non-reactive sheath around the carbon backbone of the polymer. This molecular armor prevents other chemicals from getting close enough to react.

Broad-Spectrum Resistance

This chemical inertness translates to near-universal resistance. PTFE remains unaffected by the vast majority of industrial chemicals.

This includes aggressive acids, bases, solvents, and other reactive agents. Where other plastics or even metals would corrode or dissolve, PTFE maintains its structural integrity and performance.

Proven Performance in Critical Components

This durability makes it the ideal material for components that are in constant contact with corrosive media.

Applications like seals, gaskets, bellows, and bottles made from PTFE can reliably contain or transport harsh chemicals without leaking or degrading over time.

Performance Beyond Chemical Exposure

While its chemical resistance is its most famous trait, PTFE's utility in harsh environments is amplified by its resilience to other stressors.

Extreme Temperature Tolerance

PTFE exhibits a remarkably wide operational temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This allows it to function effectively in both cryogenic applications and high-temperature processes, environments where many materials become brittle or lose their stability.

Environmental and Weathering Stability

PTFE is highly resistant to environmental factors, including UV radiation, moisture, and oxidation.

It does not degrade from exposure to harsh weather, ensuring a long shelf life and consistent performance in outdoor or unpredictable conditions.

Reliability Under Pressure and Vacuum

The material's stability extends to its physical performance. PTFE seals maintain their integrity without leaking even when containing pressurized fluids or gases.

Furthermore, its low outgassing and stability make it suitable for the vacuum of space, a testament to its reliability in extreme physical conditions.

Understanding the Trade-offs

No material is without limitations. While PTFE's performance is extraordinary, it is crucial to understand its specific boundaries to ensure proper application.

The Few Chemical Exceptions

While resistant to "nearly all" chemicals, PTFE is not completely immune. It can be attacked by a very small number of highly reactive substances.

These include molten alkali metals (like sodium), elemental fluorine, and certain rare, powerful fluorinating agents. For the vast majority of applications, these exceptions are not a concern.

Key Physical Properties

PTFE is a relatively soft material compared to metals or hard engineering plastics. This softness contributes to its excellent sealing capabilities.

However, it is more susceptible to creep (cold flow) under sustained load and has lower abrasion resistance than harder materials. Designs must account for these mechanical characteristics, especially in high-load or dynamic applications.

Making the Right Choice for Your Application

Selecting PTFE should be a decision based on a complete understanding of its performance profile against your specific needs.

- If your primary focus is containing aggressive chemicals: PTFE offers virtually unmatched reliability and is often the safest, most durable choice for handling a wide range of corrosive media.

- If your application involves extreme temperatures in addition to corrosive fluids: PTFE's dual resistance to both thermal stress and chemical attack makes it a uniquely powerful solution.

- If your design involves high mechanical loads or abrasive contact: Account for PTFE's softness by using filled grades or ensuring the mechanical design protects the PTFE component from excessive stress and wear.

Ultimately, selecting PTFE is a decision for comprehensive environmental immunity, from the chemical to the thermal.

Summary Table:

| Property | PTFE Performance |

|---|---|

| Chemical Resistance | Resistant to nearly all acids, bases, and solvents |

| Temperature Range | -200°C to 260°C (-328°F to 500°F) |

| Key Applications | Seals, gaskets, liners, labware, bellows |

| Limitations | Low abrasion resistance; attacked by molten alkali metals |

Need reliable PTFE components for your most demanding environments?

KINTEK specializes in precision-manufactured PTFE seals, liners, and labware that deliver unmatched chemical resistance and thermal stability. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom fabrication—from prototypes to high-volume orders—ensures your components perform flawlessly with aggressive chemicals and extreme temperatures.

Contact us today to discuss your specific requirements and let our expertise enhance your application's reliability and safety.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What makes PTFE suitable for medical applications? Unlock Biocompatible, Low-Friction Performance

- What raw materials are used to create Teflon? From Simple Minerals to High-Performance PTFE

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- Is Teflon biodegradable and what are its environmental impacts? Understanding the 'Forever Material'

- What is PTFE and why is it considered a valuable engineering material? Unlock Superior Performance in Demanding Applications

- What is the temperature resistance range of PTFE? Mastering Extreme Heat and Cold for Demanding Applications

- How does PTFE react to hydrogen peroxide? Discover Unmatched Chemical Resistance for Demanding Applications

- In what medical devices is PTFE commonly used? Essential Components for Safety and Reliability