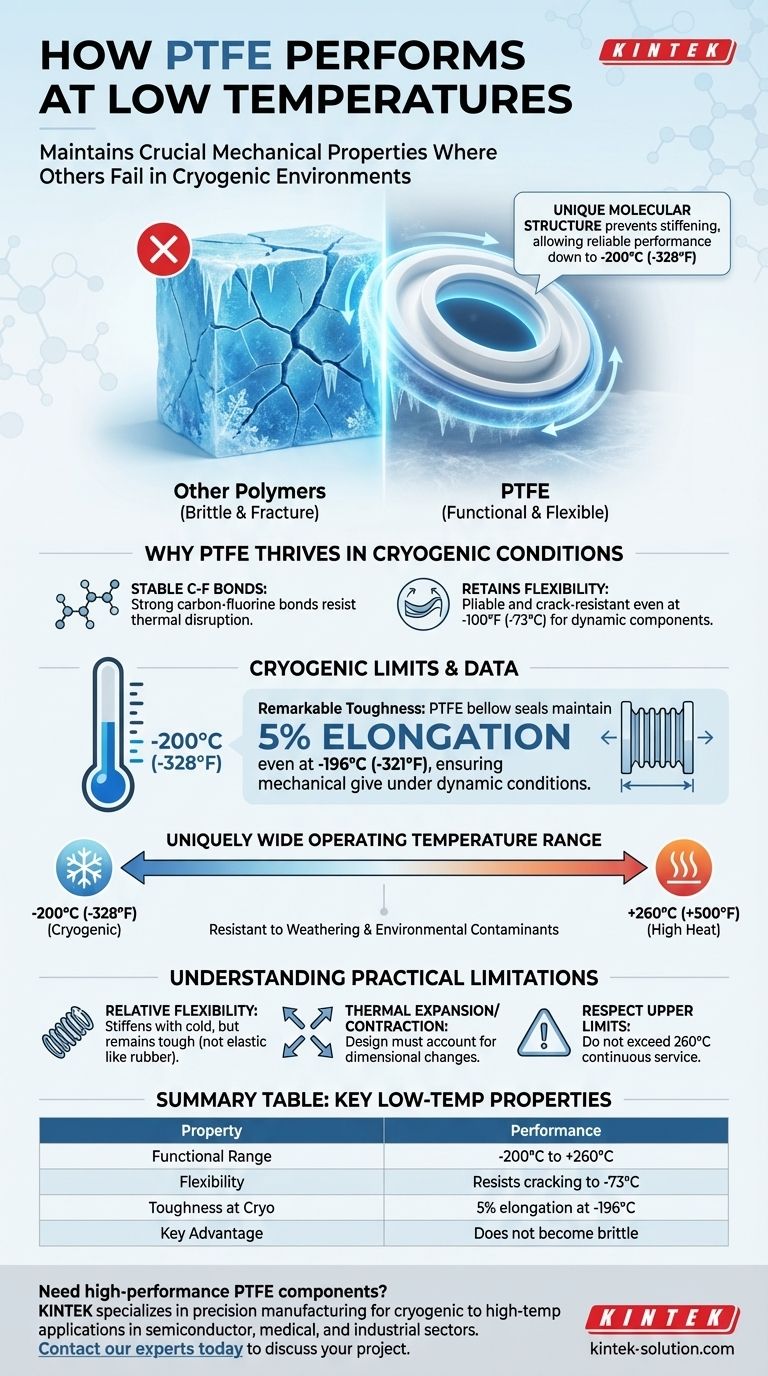

At extremely low temperatures, Polytetrafluoroethylene (PTFE) excels where many other materials fail. It maintains crucial mechanical properties in conditions that would cause other polymers to become brittle and fracture. PTFE remains functional and flexible in cryogenic environments, making it a premier choice for demanding, low-temperature applications.

The core reason to trust PTFE in the cold is not just its survival, but its ability to retain functional flexibility and toughness. Its unique molecular structure prevents it from becoming stiff or brittle, allowing it to perform reliably as a sealing or moving component even at cryogenic temperatures around -200°C (-328°F).

Why PTFE Thrives in Cryogenic Conditions

Many materials lose their useful properties when exposed to extreme cold. They become hard, brittle, and prone to catastrophic failure. PTFE, however, is engineered on a molecular level to resist these changes, making it an indispensable material for low-temperature engineering.

The Role of Molecular Structure

The exceptional performance of PTFE stems from its stable molecular structure. The strong bonds between carbon and fluorine atoms create a very stable polymer chain that is not easily disrupted by thermal energy changes. This inherent stability is what prevents the material from stiffening dramatically as temperatures plummet.

Retaining Mechanical Flexibility

Even as temperatures drop to -100°F (-73°C), PTFE remains pliable and resistant to cracking. This is a critical attribute for components like seals, gaskets, and expansion joints that must accommodate movement or pressure changes without failing.

Performance at Cryogenic Limits

PTFE’s utility extends far beyond general cold weather into true cryogenic territory. It can operate effectively in temperatures as low as -200°C (-328°F).

Remarkably, specific components like PTFE bellow seals can maintain 5% elongation even at -196°C (-321°F). This specific data point demonstrates that the material doesn't just sit inertly; it retains a degree of mechanical toughness and give, which is essential for maintaining a seal under dynamic conditions.

A Uniquely Wide Operating Temperature Range

PTFE's low-temperature capability is only half of its story. Its value is magnified by its ability to perform across an enormous thermal spectrum.

From Cryogenic Freezing to High Heat

The accepted functional temperature range for most PTFE grades is from -200°C (-328°F) up to +260°C (+500°F). This makes it one of the most versatile polymers available, suitable for applications that must endure both extreme cold and subsequent high-temperature processes, such as sterilization cycles in pharmaceutical production.

Environmental and Weather Resistance

Beyond temperature, PTFE is highly resistant to weathering and degradation from environmental contaminants. This ensures a long shelf life and reliable performance in exposed applications where cold is a recurring environmental factor.

Understanding the Practical Limitations

While PTFE's performance is impressive, no material is without trade-offs. An objective analysis requires understanding its limitations to ensure proper application design.

Flexibility is Relative

While PTFE is lauded for remaining "flexible," this term is relative. As it gets colder, its stiffness does increase, and it becomes less elastic. The 5% elongation at cryogenic temperatures is a measure of its toughness and ability to deform without fracture, not its ability to stretch like an elastomer.

Thermal Expansion and Contraction

Like all materials, PTFE expands when heated and contracts when cooled. Engineers designing components for systems that experience wide temperature swings must account for PTFE's coefficient of thermal expansion. Failure to do so can lead to loss of seal pressure or excessive mechanical stress within an assembly.

Respecting the Upper Limits

While the focus here is on cold, it's crucial to remember the material's upper limits. Continuous service temperatures should not exceed 260°C, and decomposition can begin at higher temperatures, making it unsuitable for applications that might see thermal spikes above this range.

Making the Right Choice for Your Application

Selecting PTFE is often a straightforward decision for cold environments, but your specific goal should guide your design considerations.

- If your primary focus is sealing in cryogenic systems (e.g., liquid nitrogen): PTFE is an exceptional choice, as it maintains the mechanical toughness required to hold a seal.

- If your primary focus is a flexible component in general cold weather: PTFE provides a reliable solution, easily resisting the cracking that affects other polymers at temperatures down to -100°F (-73°C).

- If your application involves extreme temperature cycling: You must design around PTFE's thermal expansion and contraction to ensure the component remains effective across the entire range.

Ultimately, PTFE's reliable and predictable performance in extreme cold makes it a foundational material for engineering in the most demanding environments.

Summary Table:

| Property | Performance at Low Temperatures |

|---|---|

| Functional Range | -200°C (-328°F) to +260°C (+500°F) |

| Flexibility | Remains pliable, resists cracking down to -73°C (-100°F) |

| Toughness at Cryogenic | Maintains 5% elongation even at -196°C (-321°F) |

| Key Advantage | Does not become brittle like many other polymers |

Need high-performance PTFE components for demanding low-temperature applications?

KINTEK specializes in the precision manufacturing of PTFE seals, liners, and labware that deliver reliable performance from cryogenic conditions up to high-temperature processes. Our custom fabrication services—from prototypes to high-volume orders—ensure your components meet exact specifications for the semiconductor, medical, laboratory, and industrial sectors.

Contact our experts today to discuss how our PTFE solutions can enhance your project's reliability and performance.

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How was Teflon historically used in armor-piercing bullets? Debunking the 'Cop-Killer' Myth

- What are the disadvantages of PTFE? Key Limitations in High-Performance Applications

- What impact has PTFE industrial coating had on daily life? Unlocking Modern Convenience & Performance

- When did the industrial production of PTFE begin? From Military Secret to Industrial Revolution

- In what industries can PTFE be used due to its properties? Essential for Demanding Sectors

- How does PTFE perform under high temperatures? Leverage Its Exceptional Thermal Stability Up to 260°C

- What is Teflon/PTFE and what are its key properties? Discover the Premier High-Performance Polymer

- What are the durability characteristics of PTFE? Superior Chemical & Thermal Resistance for Demanding Applications