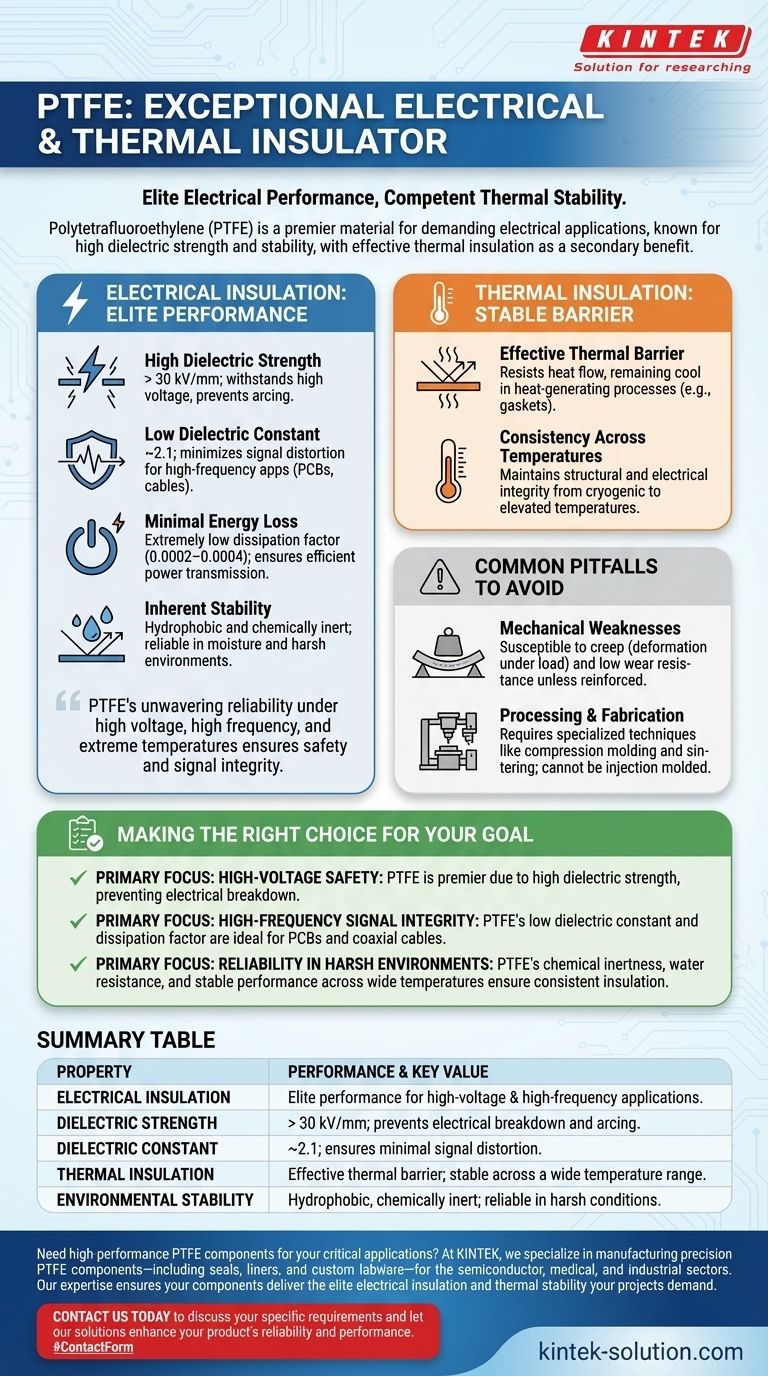

In short, Polytetrafluoroethylene (PTFE) is an exceptional electrical insulator and a competent thermal insulator. Its high dielectric strength and stability across a wide range of temperatures and frequencies make it a premier material for demanding electrical applications. While its thermal insulation is a useful secondary characteristic, its primary value lies in its elite electrical performance.

The core reason PTFE is so trusted in electronics is not just its ability to insulate, but its unwavering reliability. It maintains its superior electrical properties under high voltage, high frequencies, and extreme temperatures, ensuring both safety and signal integrity where other materials might fail.

Why PTFE Excels as an Electrical Insulator

PTFE's reputation is built on a combination of specific, high-performance electrical characteristics. These properties work together to deliver safe, efficient, and reliable insulation for sensitive and high-power systems.

High Dielectric Strength for Voltage Resistance

Dielectric strength measures a material's ability to withstand a strong electric field without breaking down and conducting electricity.

PTFE possesses a very high dielectric strength, often exceeding 30 kV/mm. This makes it an excellent choice for insulating high-voltage wiring, cables, and components, preventing dangerous electrical arcing.

Low Dielectric Constant for Signal Integrity

The dielectric constant is critical for high-frequency applications, as it affects signal speed and integrity.

With a low dielectric constant of around 2.1, PTFE minimizes signal distortion and energy loss. This is why it is a preferred material for coaxial cables, printed circuit boards (PCBs), and other high-frequency electronics.

Minimal Energy Loss (Low Dissipation Factor)

PTFE has an extremely low dissipation factor (0.0002–0.0004), meaning very little electrical energy is lost as heat when passing through the material. This ensures efficient power and signal transmission, which is crucial for sensitive electronics.

Inherent Chemical and Environmental Stability

PTFE's unique chemical structure not only blocks the flow of electrons but also makes it highly stable.

Crucially, it is hydrophobic, meaning it repels water. This prevents moisture from compromising its insulating properties, making it ideal for waterproofing and protecting electrical systems in various environments.

Understanding PTFE's Thermal Insulation

While not its most famous attribute, PTFE's thermal properties add significant value, particularly in applications where both electrical and thermal management are required.

A Stable Thermal Barrier

PTFE functions as an effective thermal insulator. This means it resists the flow of heat, a property evident in applications like industrial gaskets where the material does not become hot even during heat-generating processes.

Consistency Across Temperatures

A key advantage of PTFE is its ability to maintain its structural and electrical integrity over a very wide temperature range. Its insulating properties remain stable and predictable, whether in cryogenic conditions or at elevated temperatures, ensuring reliable performance.

Common Pitfalls to Avoid

While its electrical properties are top-tier, PTFE is not a universally perfect material for every component. Understanding its trade-offs is critical for successful engineering and design.

Mechanical Weaknesses

PTFE is a relatively soft material with lower mechanical strength compared to many engineering plastics. It can be susceptible to creep (deformation under constant load) and has poor wear resistance unless it is reinforced with fillers like glass or carbon.

Processing and Fabrication

Fabricating components from raw PTFE requires specialized techniques like compression molding and sintering. It cannot be processed using conventional melt-processing methods like injection molding, which can impact manufacturing complexity and cost.

Making the Right Choice for Your Goal

Selecting the right material requires aligning its properties with your primary objective.

- If your primary focus is high-voltage safety: PTFE is a premier choice due to its exceptionally high dielectric strength, preventing electrical breakdown.

- If your primary focus is high-frequency signal integrity: PTFE's low dielectric constant and low dissipation factor make it ideal for PCBs, coaxial cables, and connectors.

- If your primary focus is reliability in harsh environments: PTFE's chemical inertness, water resistance, and stable performance across wide temperatures ensure consistent insulation.

Ultimately, PTFE's unique combination of elite electrical insulation and environmental resilience makes it a cornerstone material for demanding electronic and industrial applications.

Summary Table:

| Property | Performance & Key Value |

|---|---|

| Electrical Insulation | Elite performance for high-voltage and high-frequency applications. |

| Dielectric Strength | > 30 kV/mm; prevents electrical breakdown and arcing. |

| Dielectric Constant | ~2.1; ensures minimal signal distortion. |

| Thermal Insulation | Effective thermal barrier; stable across a wide temperature range. |

| Environmental Stability | Hydrophobic, chemically inert; reliable in harsh conditions. |

Need high-performance PTFE components for your critical applications?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. Our expertise ensures your components deliver the elite electrical insulation and thermal stability your projects demand, from prototypes to high-volume production.

Contact us today to discuss your specific requirements and let our solutions enhance your product's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the environmental properties of PTFE? Balancing Performance with Sustainability

- How was PTFE discovered and when was it patented? The Accidental Invention of Teflon

- What are the dielectric properties of PTFE products? Ensure Stable, High-Performance Electrical Insulation

- What makes PTFE suitable for medical applications? Unlock Biocompatible, Low-Friction Performance

- How does PTFE perform at low temperatures? Unlock Reliable Cryogenic Performance

- How chemically resistant is PTFE? Discover its near-total inertness to most chemicals

- What is the dielectric constant of PTFE and why is it important? Unlock Superior Signal Integrity

- What makes Teflon suitable for low-friction applications? Unlock Superior Performance with Low-Friction PTFE