In short, PTFE packing significantly boosts equipment efficiency and reduces maintenance by leveraging its three core properties: an extremely low coefficient of friction, exceptional chemical and thermal resistance, and excellent conformability. This unique combination reduces the energy needed to operate equipment, minimizes wear on critical components like shafts, and creates a durable, long-lasting seal that requires far less frequent replacement than other materials.

The central takeaway is that PTFE packing is not just a passive sealing component; it is an active contributor to equipment health. By reducing friction and resisting degradation, it directly extends the service life of both the seal and the machinery, shifting maintenance from a reactive necessity to a predictable, long-term strategy.

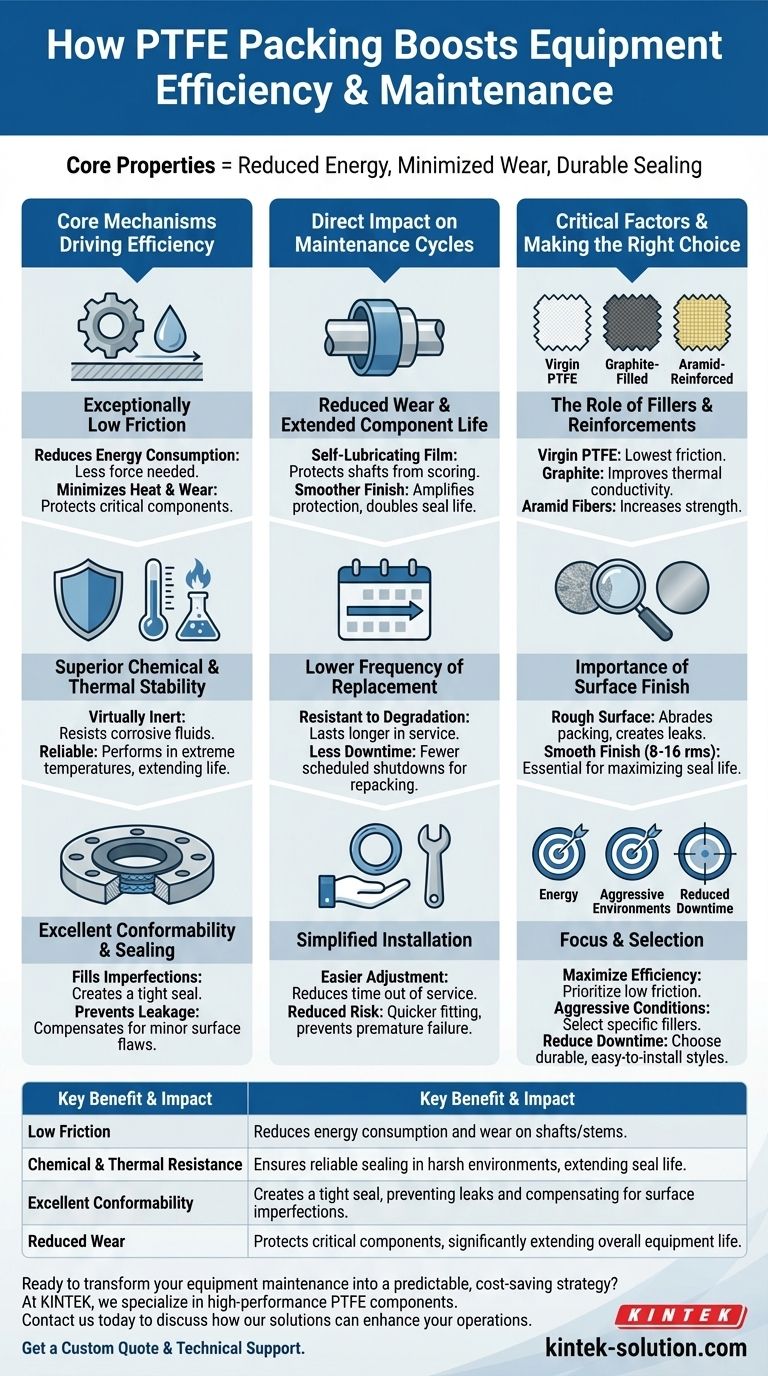

The Core Mechanisms Driving Efficiency

To understand the full impact of PTFE packing, we must first look at the fundamental material properties that set it apart. These characteristics work together to create a highly efficient and protective sealing system.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid material. This property directly translates to reduced energy consumption because pumps, valves, and other rotating equipment require less force to move.

This low-friction surface also minimizes heat generation during operation and drastically reduces abrasive wear on expensive shafts and stems, preserving their integrity and finish over time.

Superior Chemical and Thermal Stability

PTFE is virtually inert to most industrial chemicals, meaning it will not degrade, swell, or weaken when exposed to corrosive fluids. This ensures a reliable seal in aggressive environments.

Furthermore, it retains its flexibility and sealing properties across a very wide range of temperatures. Unlike other materials that can become brittle in the cold or break down in high heat, PTFE maintains its performance, extending its service life significantly.

Excellent Conformability and Sealing

PTFE packing is highly ductile, allowing it to deform and flow under pressure to fill microscopic imperfections on sealing surfaces like flanges and shafts.

This ability to conform creates an exceptionally tight seal, preventing costly product leakage. It also compensates for minor surface shortcomings, ensuring leakage prevention where more rigid materials might fail.

The Direct Impact on Maintenance Cycles

The inherent properties of PTFE translate directly into tangible reductions in maintenance frequency, downtime, and associated costs.

Reduced Wear and Extended Component Life

The most significant maintenance benefit is the protection PTFE offers to the equipment itself. By depositing a thin, lubricious film on mating surfaces, it creates a self-lubricating system that protects shafts from scoring and wear.

Improving the metal surface finish of the equipment can amplify this effect, with some studies showing that a smoother finish can double the life of the seal.

Lower Frequency of Replacement

Because PTFE packing is so resistant to chemical attack and thermal degradation, it simply lasts longer in service. This extends the time between scheduled shutdowns for repacking equipment.

This durability means fewer purchases of sealing materials over the equipment's lifecycle and, more importantly, less downtime for maintenance procedures.

Simplified Installation

Certain varieties of PTFE gland packing are specifically designed for easier installation and adjustment. This reduces the time a piece of equipment must be out of service for maintenance.

Quicker, simpler installation also reduces the risk of improper fitting, which is a common cause of premature seal failure.

Understanding the Critical Factors

While highly effective, achieving optimal performance from PTFE packing requires attention to two key factors: material selection and the condition of the equipment itself.

The Role of Fillers and Reinforcements

"PTFE packing" is a broad category. Virgin PTFE offers the lowest friction, but various fillers like graphite or reinforcements like aramid fibers are added to enhance other properties.

Graphite improves thermal conductivity and high-temperature performance, while aramid fibers dramatically increase strength and extrusion resistance. However, these fillers can slightly increase the coefficient of friction and may not produce the same ultra-smooth finish as virgin PTFE.

The Critical Importance of Surface Finish

The condition of the mating metal surface is paramount. A rough or scored shaft will act like a file, rapidly abrading the PTFE packing and destroying its sealing capability.

Rough surfaces also create microscopic leak paths that are difficult to seal, especially with small gas molecules. Investing in a proper surface finish (e.g., 8-16 rms) is essential for maximizing both seal life and performance.

Making the Right Choice for Your Application

Selecting and implementing PTFE packing correctly depends on your primary operational goal.

- If your primary focus is maximizing energy efficiency and minimizing wear: Prioritize a packing with the lowest friction and ensure the equipment's mating surface is polished to a smooth finish.

- If your primary focus is sealing in aggressive chemical or high-temperature environments: Select a PTFE packing specifically compounded with fillers like graphite that are designed to withstand those extreme conditions.

- If your primary focus is reducing maintenance downtime and labor: Choose a high-quality, durable packing and consider braided styles known for easier installation and adjustment to shorten maintenance windows.

Ultimately, leveraging PTFE packing correctly transforms equipment maintenance from a frequent problem into a predictable, long-term component of your operational strategy.

Summary Table:

| Key Benefit | Impact on Equipment |

|---|---|

| Low Friction | Reduces energy consumption and wear on shafts/stems. |

| Chemical & Thermal Resistance | Ensures reliable sealing in harsh environments, extending seal life. |

| Excellent Conformability | Creates a tight seal, preventing leaks and compensating for surface imperfections. |

| Reduced Wear | Protects critical components, significantly extending overall equipment life. |

Ready to transform your equipment maintenance into a predictable, cost-saving strategy?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision-engineered PTFE packing can help you achieve superior efficiency, reduce downtime, and protect your valuable equipment.

Whether you need a prototype or a high-volume order, our custom fabrication expertise ensures the perfect solution for your specific application. Contact us today to discuss how our PTFE solutions can enhance your operations.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some specific applications of PTFE gaskets in the chemical processing industry? Prevent Leaks in Corrosive Systems

- What factors should be considered when selecting Teflon bearings? Match Your Application's Demands for Reliability

- What is the maximum pressure that PTFE piston seals can handle? Understand the Full System of Limits

- What are the advantages of PTFE-lined pipes? Achieve Unmatched Corrosion Resistance and Purity

- What is the temperature range for virgin PTFE seals? Withstand -328°F to 500°F

- How does PTFE's chemical resistance benefit industrial applications? Boost Equipment Lifespan & Safety

- What engineering applications does PTFE have? Essential for Corrosion, Friction, and Insulation

- What design parameter must be considered when applying wide contact to spring-activated PTFE lip seals? Prevent Bell Mouthing to Avoid Catastrophic Leakage