At its core, Polytetrafluoroethylene (PTFE) minimizes sample contamination because it is one of the most chemically inert substances known. This non-reactive nature stems from the incredibly strong carbon-fluorine bonds that make up its structure. Unlike other materials, PTFE will not react with your sample, nor will it leach impurities into it, ensuring the data you collect is from the sample itself and not its container.

The central challenge in any precise analysis is eliminating unintended variables. PTFE's unique combination of chemical inertness, non-stick properties, and thermal stability makes it a superior material for protecting sample integrity where other plastics or even glass might introduce contamination.

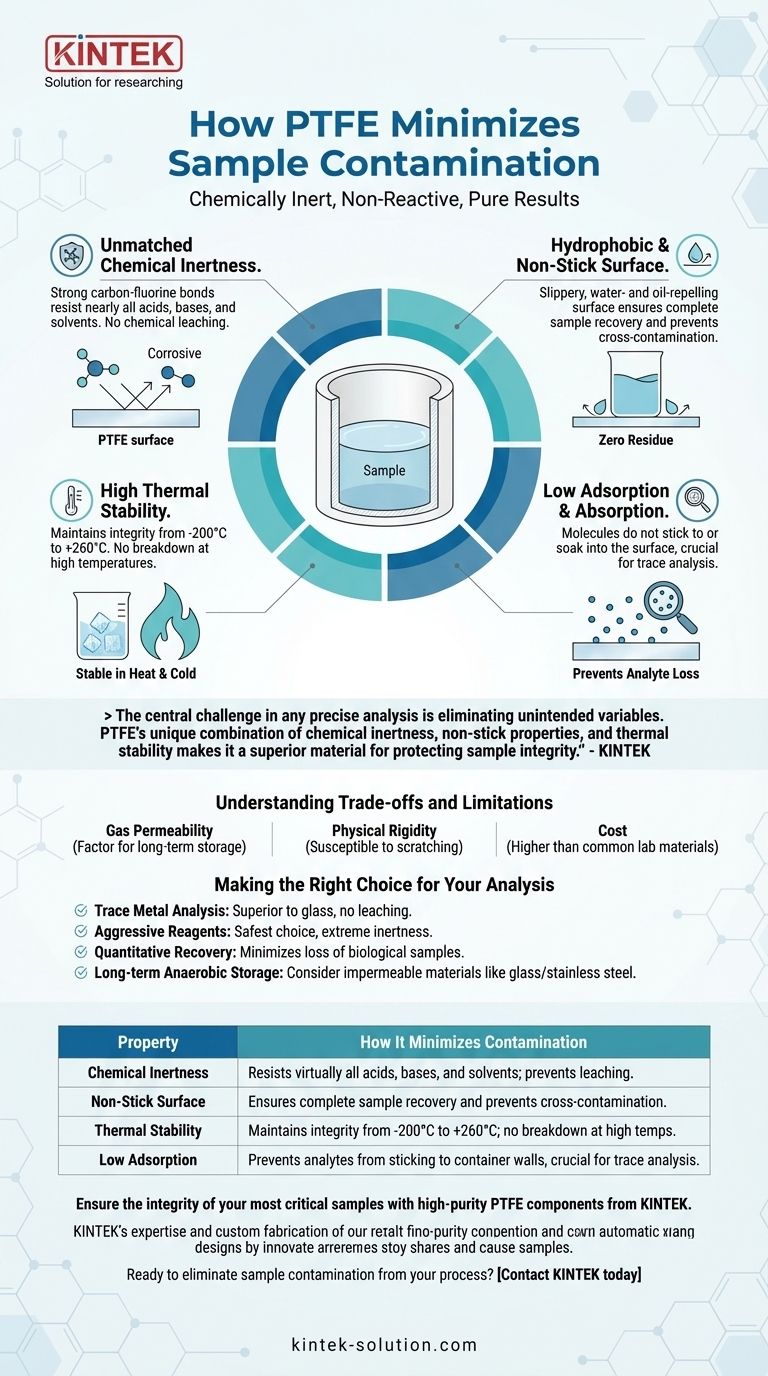

The Properties That Guarantee Sample Purity

To understand why PTFE is so effective, we need to look beyond the simple term "non-reactive" and examine the specific physical and chemical properties that contribute to its performance in a laboratory setting.

Unmatched Chemical Inertness

The defining feature of PTFE is its resistance to chemical attack. The bond between carbon and fluorine atoms is exceptionally strong and stable.

This molecular stability means PTFE is unaffected by nearly all acids, bases, and solvents. This prevents the container itself from degrading and releasing constituent chemicals into your sample.

Hydrophobic and Non-Stick Surface

PTFE is highly hydrophobic (water-repelling) and oleophobic (oil-repelling). This results in a slippery, non-stick surface that is difficult for substances to adhere to.

This property is critical for two reasons: it ensures complete sample recovery and prevents cross-contamination. Because virtually nothing sticks to the surface, you can be confident you are transferring your entire sample and that residues from previous analyses are not lingering.

High Thermal Stability

Many analytical procedures require heating or cooling. PTFE maintains its structural integrity and chemical inertness across a very wide temperature range (typically -200°C to +260°C).

A material that is not thermally stable can break down at high temperatures, releasing volatile organic compounds or other contaminants. PTFE's stability eliminates this risk.

Low Adsorption and Absorption

PTFE exhibits extremely low adsorption (where molecules stick to the surface) and absorption (where molecules soak into the material).

This is vital for trace analysis, where the target analyte exists in very low concentrations. If the container walls bind to even a small fraction of the analyte, it can significantly skew the final measurement.

Understanding the Trade-offs and Limitations

While PTFE is an exceptional material, no single solution is perfect for every application. Being an effective advisor means acknowledging the practical limitations.

Gas Permeability

Despite being a solid, PTFE has a microporous structure that allows for some permeability to gases. This is generally not an issue for short-term lab work but can be a factor in the long-term storage of gas-sensitive samples.

Physical Rigidity

PTFE is a relatively soft polymer compared to glass or metal. It can be susceptible to scratching and deformation, which requires careful handling to maintain a pure, untarnished surface.

Cost

High-purity, virgin PTFE is more expensive than common lab materials like polypropylene or borosilicate glass. Its use is often a calculated investment in the quality and reliability of analytical results.

Making the Right Choice for Your Analysis

Your choice of labware should be a deliberate decision based on the specific demands of your experiment.

- If your primary focus is trace metal analysis: PTFE is superior to glass, which can leach sodium, boron, and other metallic ions into your sample.

- If your primary focus is working with aggressive reagents: PTFE's extreme inertness to strong acids, bases, and organic solvents makes it the safest and most reliable choice.

- If your primary focus is quantitative recovery of biological samples: The non-stick surface of PTFE minimizes the loss of precious proteins or DNA that can adhere to other types of plastic or glass.

- If your primary focus is long-term anaerobic storage: You may need to consider an impermeable material like glass or stainless steel to prevent gas exchange.

Ultimately, selecting PTFE is a strategic decision to minimize container-induced variables and ensure your results accurately reflect your sample, not your equipment.

Summary Table:

| Property | How It Minimizes Contamination |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents; prevents leaching. |

| Non-Stick Surface | Ensures complete sample recovery and prevents cross-contamination. |

| Thermal Stability | Maintains integrity from -200°C to +260°C; no breakdown at high temps. |

| Low Adsorption | Prevents analytes from sticking to container walls, crucial for trace analysis. |

Ensure the integrity of your most critical samples with high-purity PTFE components from KINTEK.

Whether you are working in the semiconductor, medical, laboratory, or industrial sector, contamination can compromise your results and your reputation. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—that are engineered to meet the highest standards of chemical resistance and purity.

We understand the unique challenges of specialized industries and offer custom fabrication services, from rapid prototypes to high-volume production runs, to deliver the exact solution you need.

Ready to eliminate sample contamination from your process? Contact KINTEK today to discuss your application and receive a quote for custom PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the key requirements for materials used in chemical laboratories? Ensure Safety and Data Integrity

- What are the key properties of Teflon membranes? Ensure Chemical Resistance and Sample Purity

- What are PTFE lined caps made of? A Guide to Their Inert, Protective Construction

- What are the key advantages of using PTFE chromatography vials? Ensure Sample Integrity and Accurate Results

- What are the key applications of the PTFE bottle? Ensure Chemical Safety and Sample Purity

- What makes PTFE vials effective in preventing sample contamination or evaporation? Superior Chemical Inertness & Airtight Seals

- What role does precision play in the use of PTFE silicone septa for pharmaceutical analysis? Ensure Reliable, Compliant Data

- What are the key properties that make PTFE shovels ideal for laboratory use? Ensure Sample Integrity with Chemically Inert Tools