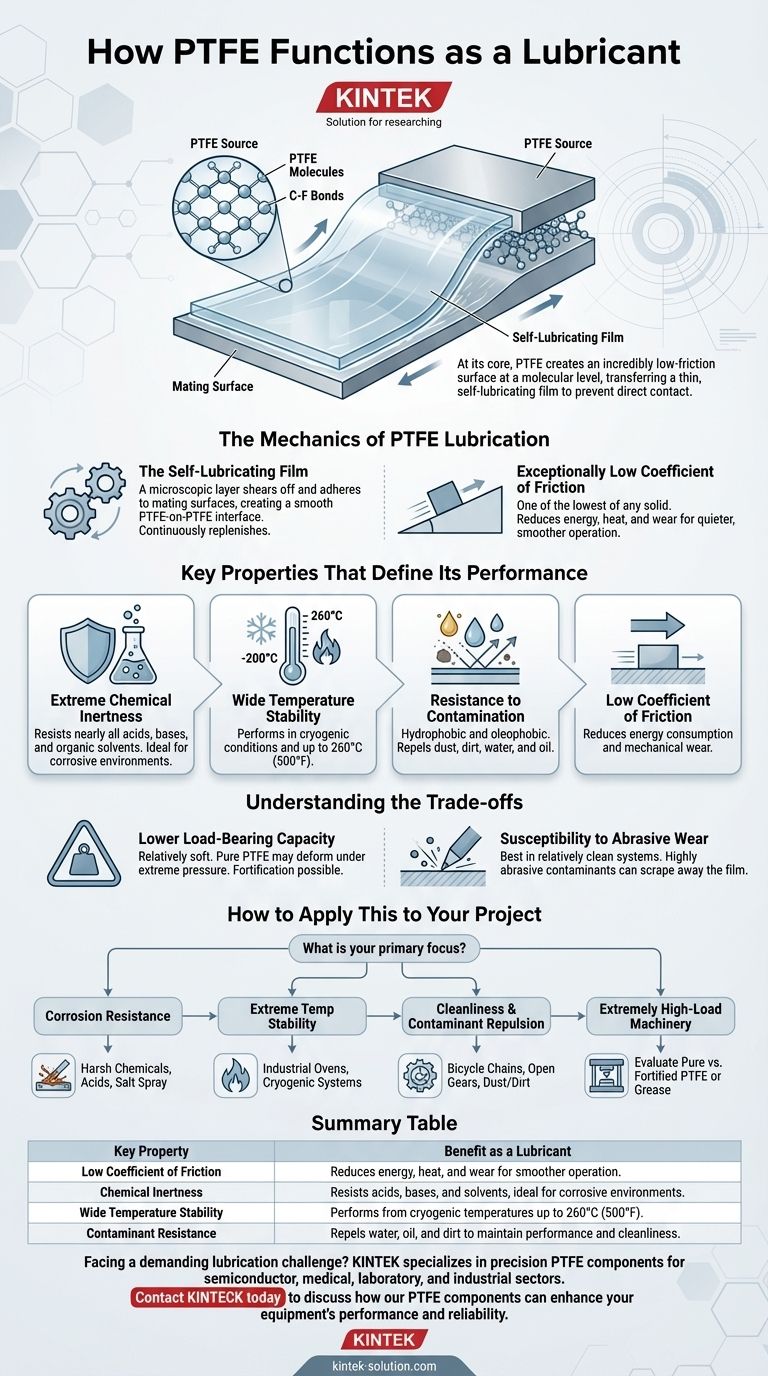

At its core, Polytetrafluoroethylene (PTFE) functions as a lubricant by creating an incredibly low-friction surface at a molecular level. Its unique chemical structure allows it to transfer a thin, self-lubricating film onto mating surfaces, effectively preventing direct contact and dramatically reducing the force needed to overcome friction and wear.

While PTFE is famous for its "non-stick" low friction, its true value as a lubricant comes from its unique combination of properties. It delivers consistent performance in environments where traditional oils and greases would fail, such as in the presence of harsh chemicals or extreme temperatures.

The Mechanics of PTFE Lubrication

PTFE's effectiveness is not due to a single trait but a combination of its physical and chemical properties. Understanding these mechanics is key to knowing when and where to use it.

The Self-Lubricating Film

When two surfaces are in motion with PTFE between them, a microscopic layer of the material shears off and adheres to the mating surfaces. This creates a smooth, PTFE-on-PTFE interface.

This "transfer film" is the essence of its self-lubricating property. It continuously replenishes the low-friction layer as long as the PTFE source is present.

An Exceptionally Low Coefficient of Friction

PTFE possesses one of the lowest coefficients of friction of any known solid material. This inherent slipperiness is the primary reason it reduces the energy required to move parts against each other.

This property directly translates to reduced heat generation, quieter operation, and less mechanical wear on components like chain links and sprockets.

Key Properties That Define Its Performance

Beyond low friction, several other characteristics make PTFE a powerful and versatile lubricant for challenging applications.

Extreme Chemical Inertness

The strength of the carbon-fluorine bonds in PTFE's molecular structure makes it virtually immune to chemical attack.

It resists nearly all acids, bases, and organic solvents. This makes it the ideal lubricant for systems operating in corrosive or chemically aggressive environments.

Wide Temperature Stability

PTFE maintains its integrity and lubricating properties across an exceptionally broad temperature range.

It can withstand continuous service temperatures up to 260°C (500°F) and remains effective in cryogenic conditions, environments where conventional oils would burn off or freeze solid.

Resistance to Contamination

PTFE's non-stick nature actively repels contaminants like dust and dirt, preventing them from creating an abrasive slurry that accelerates wear.

Furthermore, its hydrophobic (water-repelling) and oleophobic (oil-repelling) properties ensure it performs reliably in wet or oily conditions without absorbing moisture or degrading.

Understanding the Trade-offs

No single solution is perfect for every problem. To use PTFE effectively, it's critical to understand its limitations.

Lower Load-Bearing Capacity

As a relatively soft material, pure PTFE may not be suitable for extremely high-pressure applications where it could be squeezed out or deformed. It can be fortified with other materials to improve this, but it is an important consideration.

Susceptibility to Abrasive Wear

While PTFE repels dust, highly abrasive contaminants can physically scrape away the lubricating film or the solid PTFE part itself over time. It performs best in relatively clean mechanical systems.

How to Apply This to Your Project

Choosing the right lubricant depends entirely on the operational environment and performance goals.

- If your primary focus is corrosion resistance: PTFE is an outstanding choice for machinery exposed to harsh chemicals, acids, or salt spray.

- If your primary focus is extreme temperature stability: Use PTFE in applications like industrial ovens or cryogenic systems where oils and greases would fail.

- If your primary focus is cleanliness and contaminant repulsion: PTFE-based lubricants are ideal for applications like bicycle chains or open gears where repelling dust and dirt is critical.

- If your primary focus is extremely high-load machinery: You should evaluate if pure PTFE is sufficient, or if a fortified PTFE compound or a different type of grease is required.

Ultimately, understanding these core principles allows you to deploy PTFE not just as a lubricant, but as a precise engineering solution for your most demanding challenges.

Summary Table:

| Key Property | Benefit as a Lubricant |

|---|---|

| Low Coefficient of Friction | Reduces energy consumption, heat, and wear for smoother operation. |

| Chemical Inertness | Resists acids, bases, and solvents, ideal for corrosive environments. |

| Wide Temperature Stability | Performs from cryogenic temperatures up to 260°C (500°F). |

| Contaminant Resistance | Repels water, oil, and dirt to maintain performance and cleanliness. |

Facing a demanding lubrication challenge? KINTEK specializes in precision PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get the exact low-friction, chemically inert solution your application requires, from prototypes to high-volume orders.

Contact KINTECK today to discuss how our PTFE components can enhance your equipment's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application