At its core, PTFE ensures seal integrity in chromatography vials by creating a chemically inert and non-stick barrier between the sample and the cap liner. This prevents sample interaction, contamination, and evaporation, while the physical properties of the septum it is bonded to provide the mechanical force needed to maintain a tight seal against the vial rim, even after being punctured.

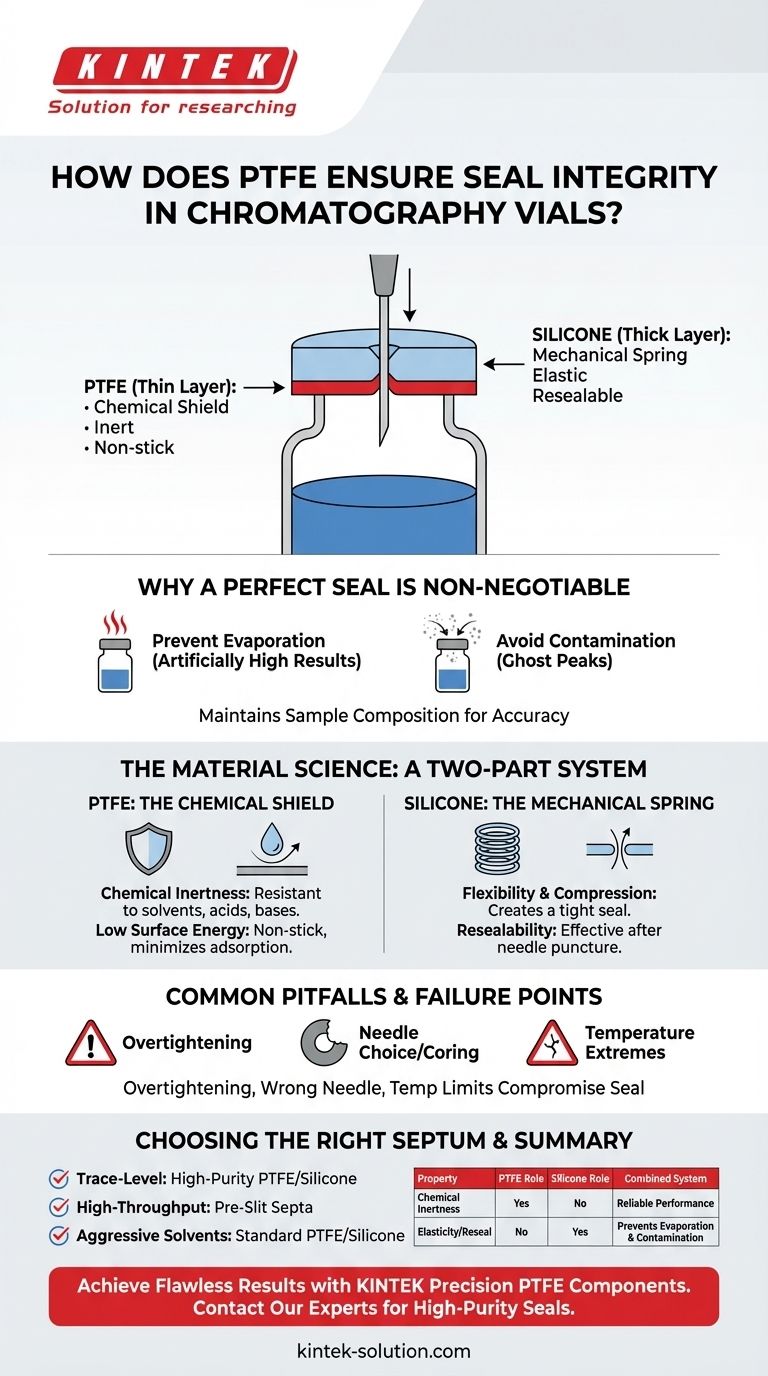

The integrity of a chromatography vial seal does not come from PTFE alone. It is the result of a two-part system: a thin PTFE film provides the essential chemical resistance, while a thicker, elastic silicone layer provides the resealable mechanical force required for a consistently reliable seal.

Why a Perfect Seal is Non-Negotiable

In chromatography, the goal is to precisely measure the components of a sample. Any change in the sample's composition between preparation and analysis directly compromises the accuracy and reproducibility of the results.

Preventing Sample Evaporation

A poor seal allows volatile solvents to evaporate over time, especially in an autosampler waiting queue. This increases the concentration of your analytes, leading to artificially high quantitative results.

Avoiding External Contamination

The seal acts as a barrier against atmospheric contaminants, such as dust, fibers, or other volatile compounds in the lab environment. A compromised seal can allow these contaminants to enter the vial and appear as ghost peaks in your chromatogram.

The Material Science of a PTFE/Silicone Septum

The most common and effective vial seals use a septum made of two distinct materials bonded together: PTFE and silicone. Each material plays a specific and complementary role.

The Role of PTFE: The Chemical Shield

The side of the septum that faces your sample is a very thin layer of Polytetrafluoroethylene (PTFE). This material is chosen for its exceptional properties.

Its primary benefit is chemical inertness. PTFE is resistant to virtually all common solvents, acids, and bases used in chromatography, ensuring it will not react with your sample or leach impurities into it.

PTFE also has a low surface energy, which gives it its famous non-stick quality. This minimizes the risk of trace-level analytes adsorbing onto the septum surface, which is critical for ensuring high sample recovery.

The Role of Silicone: The Mechanical Spring

While PTFE is a perfect chemical barrier, it is not very elastic. On its own, it would not form a reliable, resealable closure.

This is where silicone comes in. The thicker layer of the septum is made of high-purity silicone, which acts as a flexible, rubber-like spring. It provides the physical compressibility needed to create a tight seal when the cap is tightened.

Crucially, silicone's elasticity allows it to reseal effectively after being punctured by an autosampler needle. This maintains the seal's integrity for subsequent injections or long-term storage.

Common Pitfalls and Failure Points

Even with the right materials, user error or improper selection can compromise the seal. Understanding these potential issues is key to preventing them.

The Risk of Overtightening

It is a common misconception that a tighter cap creates a better seal. Overtightening can deform the septum, causing it to extrude or wrinkle, which breaks the seal and can even cause the needle to bend or break.

The Impact of Needle Choice

Using a needle with too large a gauge or a blunt tip can core the septum, tearing out a small piece of material instead of piercing it cleanly. This permanent hole will not reseal and guarantees sample evaporation and contamination.

Temperature Limitations

While PTFE/silicone septa have a wide operating temperature range, extreme heat can cause the silicone to lose its elasticity, and extreme cold can make it brittle. Always operate within the manufacturer's specified temperature limits.

How to Choose the Right Septum for Your Analysis

Your analytical goal should dictate your choice of vial and septum.

- If your primary focus is trace-level analysis: Prioritize high-purity PTFE/silicone septa to ensure minimal adsorption and prevent leachable contaminants from interfering with your results.

- If your primary focus is high-throughput screening: Consider pre-slit septa, which reduce the force needed for needle penetration, minimizing coring and preventing vacuum formation inside the vial.

- If your primary focus is compatibility with aggressive solvents: The chemical inertness of the PTFE layer is the most critical factor, making standard PTFE/silicone septa the default, reliable choice for nearly all applications.

Understanding the materials in your vial is the first step toward achieving reliable and reproducible analytical results.

Summary Table:

| Property | Role in Seal Integrity |

|---|---|

| PTFE Layer | Provides chemical inertness and a non-stick surface to prevent sample interaction and adsorption. |

| Silicone Layer | Supplies the mechanical elasticity and compression needed for a tight, resealable closure after needle puncture. |

| Combined System | Ensures reliable performance by preventing evaporation, contamination, and maintaining sample integrity for accurate chromatography. |

Achieve flawless chromatography results with precision PTFE components from KINTEK.

Your analysis depends on the integrity of every vial seal. KINTEK specializes in manufacturing high-purity PTFE seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We ensure your components offer the chemical resistance and reliable performance you need, from custom prototypes to high-volume production.

Let us help you eliminate contamination and ensure data accuracy. Contact our experts today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application