At its core, Polytetrafluoroethylene (PTFE) enhances the integrity of sealed vials by serving as a completely non-reactive barrier between the sample and the cap closure. This chemical inertness prevents contamination, sample degradation, or reaction with the closure material, while its physical properties create a secure seal that stops evaporation and protects against the external environment.

The fundamental challenge in sample containment is ensuring the container itself does not alter the sample. PTFE solves this by making the vial's cap as chemically neutral and impenetrable as the vial body, guaranteeing the sample remains pure, stable, and at its intended concentration.

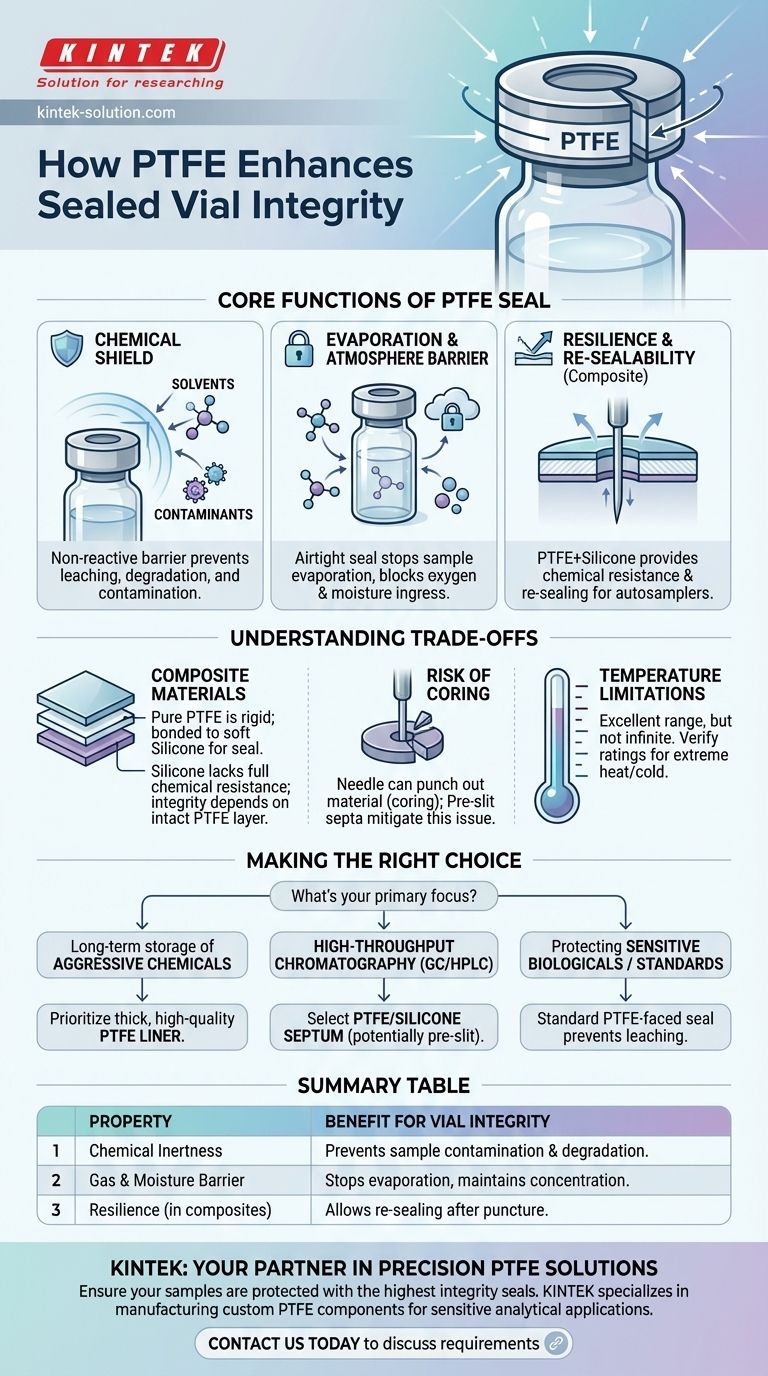

The Core Functions of a PTFE Seal

To understand PTFE's value, we must look at its dual role as both a chemical shield and a physical barrier. These two functions work together to maintain total sample integrity.

Creating a Chemically Inert Barrier

PTFE is one of the most non-reactive materials known. Placing a thin layer of it on the side of the cap liner or septum that faces the sample effectively creates a shield.

This shield prevents any chemical interaction. Aggressive solvents won't degrade the cap liner, and sensitive samples won't have chemicals leach into them from the closure materials, ensuring the purity of the vial's contents.

Preventing Evaporation and Atmospheric Exchange

A primary role of any vial seal is to be airtight. The physical properties of PTFE, often bonded to a more compressible material like silicone, create a tight, conforming seal against the rim of the vial.

This secure seal is critical for preventing the evaporation of volatile sample components, which would alter the sample's concentration and invalidate analytical results. It also blocks oxygen or moisture from the atmosphere from entering the vial and potentially degrading the sample over time.

Ensuring Resilience and Re-Sealability

In applications like chromatography, vials are often accessed via an autosampler needle that pierces the cap's septum. Here, PTFE/silicone composite septa are standard.

The PTFE layer provides the chemical protection, while the thicker silicone layer provides elastic resilience. The silicone allows the septum to form a tight seal and, more importantly, to re-seal itself after being punctured, protecting the sample from evaporation between multiple injections.

Understanding the Trade-offs

While PTFE is a superior material, its application in vial seals involves practical considerations and trade-offs. Acknowledging these is key to proper use.

The Role of Composite Materials

Pure PTFE can be somewhat rigid and does not have the "springiness" needed for a perfect, re-sealing closure. This is why it is almost always bonded to a softer material, most commonly silicone.

The integrity of the seal depends on the PTFE layer remaining intact. The underlying silicone does not share PTFE's universal chemical resistance, so a compromised PTFE layer could lead to sample contamination.

Risk of "Coring" During Puncture

When a needle pierces a septum, it can sometimes punch out a small piece of the material—a phenomenon known as coring. If a piece of the PTFE/silicone septum falls into the sample, it becomes a source of contamination.

Pre-slit septa are designed to mitigate this issue. The slit guides the needle through the septum, reducing the force required for piercing and minimizing the risk of coring.

Temperature Limitations

PTFE has an excellent operational temperature range, but it is not infinite. For applications involving extreme heat or cryogenic freezing, you must verify that the specific PTFE/silicone composite used is rated for those temperatures to avoid seal failure.

Making the Right Choice for Your Application

The ideal seal depends entirely on the chemical nature of your sample and how you intend to use it.

- If your primary focus is long-term storage of aggressive chemicals: Prioritize a seal with a thick, high-quality PTFE liner to provide the most robust chemical shield.

- If your primary focus is high-throughput chromatography (GC/HPLC): Select a PTFE/silicone septum, potentially with a pre-slit, to ensure reliable re-sealing and prevent evaporation after multiple needle punctures.

- If your primary focus is protecting sensitive biologicals or standards: A standard PTFE-faced seal is critical to prevent even trace amounts of leaching from the closure material, which could compromise your sample.

Ultimately, choosing the correct PTFE-based seal transforms the vial from a simple container into a reliable component of your analytical system.

Summary Table:

| Property | Benefit for Vial Integrity |

|---|---|

| Chemical Inertness | Prevents sample contamination and degradation by creating a non-reactive barrier. |

| Gas & Moisture Barrier | Stops evaporation and protects against atmospheric exchange to maintain concentration. |

| Resilience (in composites) | Allows for re-sealing after needle puncture, ideal for autosampler use. |

Ensure your samples are protected with the highest integrity seals.

KINTEK specializes in manufacturing precision PTFE components, including custom vial seals, septa, and liners for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in PTFE fabrication ensures your sensitive samples are shielded from contamination and evaporation, guaranteeing the accuracy of your analytical results.

Whether you need a standard solution or a custom-designed seal for aggressive chemicals, high-throughput chromatography, or sensitive biologicals, we can deliver from prototype to high-volume production.

Contact us today to discuss your specific requirements and enhance your sample containment system with KINTEK's precision PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do PTFE/silicone septa reduce sample carryover in HPLC analysis? Achieve Accurate, Contamination-Free Results

- What types of solvents and reagents are PTFE vials compatible with? Ensure Purity in Your HPLC/GC Analysis

- What are the advantages of PTFE in pharmaceutical and biotech research? Ensure Purity and Prevent Contamination

- What are the key features of PTFE reagent bottles? Superior Chemical Resistance and Durability

- What temperature range can PTFE Tri-Clamp gaskets withstand? -200°C to 260°C for Extreme Applications

- What customization options are available for PTFE-lined bottle caps? Tailor Caps for Chemical & Temperature Resistance

- What sizes and pore options are available for PTFE filters? Choose the Right Filter for Your Application

- What are the key properties of Teflon that make it suitable for medical applications? Unlock Biocompatibility & Performance