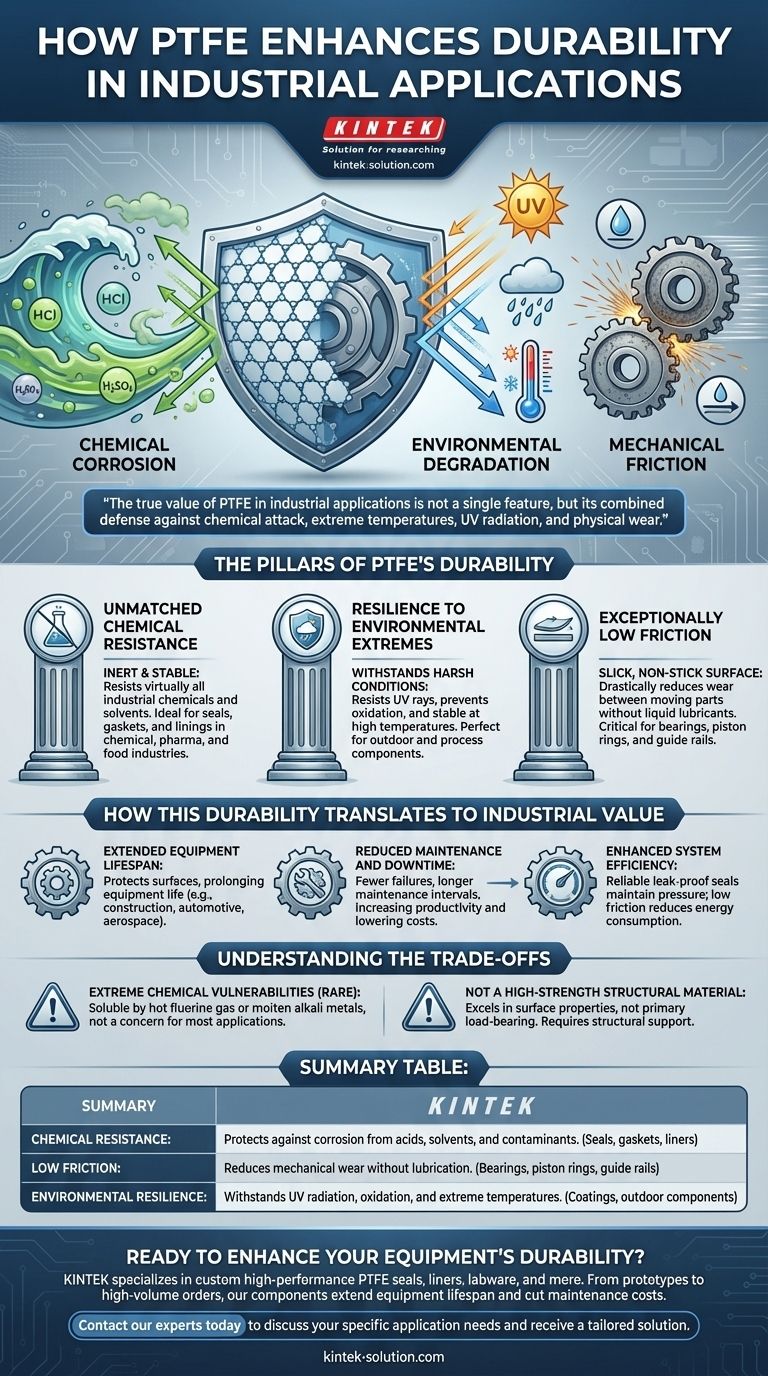

At its core, Polytetrafluoroethylene (PTFE) enhances durability by creating a highly resilient barrier against the three primary agents of industrial wear: chemical corrosion, environmental degradation, and mechanical friction. Its unique molecular structure makes it exceptionally inert and stable, allowing it to protect components in conditions where most other materials would quickly fail. This translates directly to a longer equipment lifespan and significantly reduced maintenance needs.

The true value of PTFE in industrial applications is not a single feature, but its combined defense against chemical attack, extreme temperatures, UV radiation, and physical wear. This multifaceted resilience is what makes it a critical material for enhancing durability and operational reliability.

The Pillars of PTFE's Durability

To understand why PTFE is so effective, we need to look at its fundamental properties. Each one addresses a specific and common cause of component failure in demanding environments.

Unmatched Chemical Resistance

PTFE is famously inert, meaning it does not react with most substances. It is resistant to virtually all industrial chemicals and solvents.

This makes it an ideal material for seals, gaskets, and linings in the chemical processing, pharmaceutical, and food industries, where exposure to harsh or contaminating materials is constant.

Resilience to Environmental Extremes

Components used outdoors or in high-temperature processes face constant assault from the environment. PTFE excels at withstanding these conditions.

It resists damage from UV rays, prevents oxidation, and does not become brittle in the cold. Furthermore, its very high melting point ensures stability and performance in high-temperature applications.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a slick, non-stick surface.

This property is critical for mechanical parts that cannot use traditional liquid lubricants, such as bearings, piston rings, and guide rails. It drastically reduces wear and tear between moving parts, extending their operational life.

How This Durability Translates to Industrial Value

The physical properties of PTFE provide direct, measurable benefits in an industrial setting. The result is a more efficient, reliable, and cost-effective operation.

Extended Equipment Lifespan

By protecting surfaces from corrosion, weather, and friction, PTFE coatings and components directly prolong the life of the equipment they are part of. This is a primary driver for its use in construction, automotive, and aerospace applications.

Reduced Maintenance and Downtime

More durable parts mean fewer failures. Using PTFE gaskets, seals, and bearings leads to longer intervals between maintenance cycles.

This reduction in scheduled and unscheduled downtime is a massive benefit, increasing productivity and lowering operational costs over the equipment's lifespan.

Enhanced System Efficiency

Reliable, leak-proof seals ensure that systems maintain pressure and prevent loss of valuable materials. In mechanical systems, low-friction components reduce the energy required for operation.

This contributes to more efficient and predictable performance, from chemical pipelines to complex machinery.

Understanding the Trade-offs

While exceptionally durable in many respects, PTFE is not a universal solution. Understanding its limitations is key to using it effectively.

Extreme Chemical Vulnerabilities

Despite its incredible resistance, PTFE is not completely invincible. It can be dissolved by highly specific and rare conditions, such as hot fluorine gas or certain molten alkali metals.

For the vast majority of industrial applications, this is not a practical concern, but it is a known limitation.

Not a High-Strength Structural Material

The primary value of PTFE lies in its surface properties and stability, not its raw tensile or compressive strength. It excels as a coating, a sealant, or a low-friction surface.

It is not designed to be used as a primary load-bearing structural component in the way steel or other alloys are.

Making the Right Choice for Your Application

Selecting PTFE should be based on the specific environmental and operational challenges you face.

- If your primary focus is preventing chemical corrosion: PTFE is an industry-leading choice for seals, gaskets, and linings due to its near-total chemical inertness.

- If your primary focus is reducing mechanical wear: Its exceptionally low friction makes PTFE ideal for non-lubricated bearings, piston rings, and sliding components.

- If your primary focus is outdoor or weather-exposed equipment: PTFE coatings provide outstanding protection against UV radiation, oxidation, and temperature fluctuations.

By leveraging its unique combination of resistances, PTFE serves as a foundational material for building more resilient and efficient industrial systems.

Summary Table:

| Key Property | Durability Benefit | Common Applications |

|---|---|---|

| Chemical Resistance | Protects against corrosion from acids, solvents, and contaminants. | Seals, gaskets, liners in chemical/pharma industries. |

| Low Friction | Reduces mechanical wear between moving parts without lubrication. | Bearings, piston rings, guide rails in machinery. |

| Environmental Resilience | Withstands UV radiation, oxidation, and extreme temperatures. | Coatings and components for outdoor or high-heat equipment. |

Ready to enhance your equipment's durability with precision PTFE components?

KINTEK specializes in custom fabricating high-performance PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, our components are engineered to provide unmatched chemical resistance, reduce friction, and withstand harsh environments—directly extending your equipment's lifespan and cutting maintenance costs.

Contact our experts today to discuss your specific application needs and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the electrical insulation properties of PTFE caps? Superior Dielectric Performance for Demanding Applications

- Why is understanding material limits important when choosing PTFE seals? Avoid Premature Failure

- Are PTFE filler specifications typically by weight or volume? Unlock the Key to Material Performance

- What are Teflon bushings made from? Discover the Power of PTFE for High-Performance Applications

- Where are PTFE energized seals typically used in cryogenic applications? Critical Seals for LNG & Aerospace

- Why is selecting the right PTFE packing important? Ensure Reliable Sealing & Prevent Costly Failures

- What are the key properties of PTFE? Unmatched Chemical, Thermal, and Friction Performance

- What makes PTFE bellows easier to sanitize? Superior Non-Stick & Chemical Resistance for Critical Processes