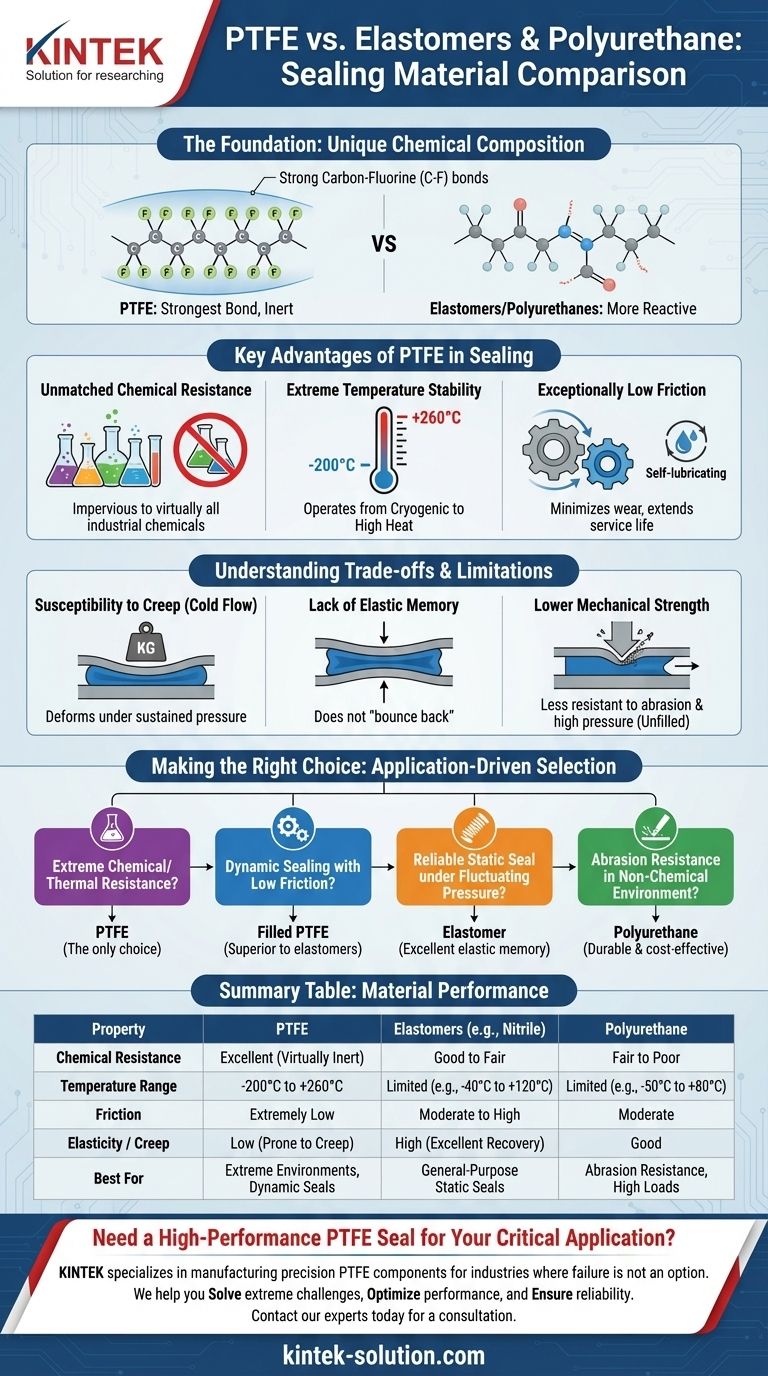

Fundamentally, PTFE differs from elastomers and polyurethanes due to its unique chemical composition as a fluoropolymer. Its atomic structure, built on incredibly strong carbon-fluorine bonds, gives it a combination of extreme chemical inertness, a vast operating temperature range, and a very low coefficient of friction that other materials cannot match. While elastomers offer flexibility and polyurethanes provide toughness, PTFE excels in the most demanding chemical and thermal environments.

The decision to use PTFE is not about finding a universally "better" material, but about matching its distinct profile to a specific engineering challenge. PTFE is the default choice for extreme environments, but its mechanical limitations, like a tendency to deform under load, must be understood.

The Foundation: What Makes PTFE Structurally Different?

PTFE’s properties are not accidental; they are a direct result of its molecular makeup. Understanding this chemical basis is key to understanding its performance.

The Carbon-Fluorine Bond

At the heart of PTFE is the bond between carbon and fluorine atoms. This is one of the strongest single bonds in organic chemistry.

This powerful bond is what gives PTFE its signature thermal stability and near-total resistance to chemical attack. Most other polymers, like elastomers, rely on weaker carbon-hydrogen bonds that are more susceptible to heat and chemical reactions.

A Fluoropolymer, Not an Elastomer

PTFE is a type of plastic, not a rubbery elastomer. It does not contain the elastic compounds that allow materials like nitrile or EPDM to "bounce back" after being compressed.

This distinction is critical. While elastomers can maintain a seal through fluctuating pressures by expanding and contracting, PTFE is relatively rigid.

Key Advantages of PTFE in Sealing

The unique structure of PTFE creates a set of advantages that make it indispensable for certain applications.

Unmatched Chemical Resistance

PTFE is impervious to virtually all industrial chemicals, solvents, acids, and bases. This makes it an essential material for sealing in pharmaceutical, chemical processing, and semiconductor industries.

The only common exceptions are molten alkali metals (like sodium) and certain potent halogenated compounds. For nearly all other applications, it is completely inert.

Extreme Temperature Stability

PTFE seals maintain their integrity across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

Most elastomers and polyurethanes become brittle at low temperatures or degrade rapidly at high temperatures, making PTFE the only viable option for cryogenic or high-heat processes.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "self-lubricating" property is invaluable in dynamic seals.

In applications with moving parts, like in ball valves or on rotating shafts, PTFE seals minimize wear, reduce operational torque, and significantly extend the service life of the equipment.

Understanding the Trade-offs and Limitations

No material is perfect. To use PTFE effectively, you must be aware of its inherent disadvantages compared to more conventional sealing materials.

Susceptibility to Creep (Cold Flow)

The most significant drawback of PTFE is its tendency to creep, or "cold flow." Under sustained pressure, the material will slowly and permanently deform.

This deformation can cause the seal to loosen over time, leading to leaks. This is a primary reason why elastomers, with their excellent elastic recovery, are preferred for many general-purpose static sealing applications.

Lack of Elastic Memory

Because it is not an elastomer, a standard PTFE seal does not return to its original shape after the compressive load is removed.

This makes it less effective at maintaining a seal in applications with vibration, pressure cycles, or thermal expansion and contraction. Specialized variants like expanded PTFE (ePTFE) are engineered to improve this property.

Lower Mechanical Strength

Compared to a hard material like polyurethane, unfilled PTFE is relatively soft and has lower resistance to abrasion and high-pressure extrusion.

To counteract this, PTFE is often blended with fillers like glass, bronze, or carbon. These fillers significantly improve its mechanical strength, load-bearing capacity, and resistance to creep.

Making the Right Choice for Your Application

Selecting a sealing material requires balancing the demands of the application with the properties of the material.

- If your primary focus is extreme chemical or thermal resistance: PTFE is almost always the correct and only choice.

- If your primary focus is dynamic sealing with low friction and wear: A filled PTFE seal is a superior choice over most elastomers.

- If your primary focus is a reliable static seal under fluctuating pressure: An elastomer is often better due to its excellent elastic memory and resistance to compression set.

- If your primary focus is abrasion resistance in a non-chemical environment: A polyurethane seal may provide better durability and be more cost-effective.

Ultimately, choosing the right seal is about matching the material's strengths to your application's most critical demands.

Summary Table:

| Property | PTFE | Elastomers (e.g., Nitrile) | Polyurethane |

|---|---|---|---|

| Chemical Resistance | Excellent (Virtually Inert) | Good to Fair | Fair to Poor |

| Temperature Range | -200°C to +260°C | Limited (e.g., -40°C to +120°C) | Limited (e.g., -50°C to +80°C) |

| Friction | Extremely Low (Self-Lubricating) | Moderate to High | Moderate |

| Elasticity / Creep | Low Elasticity (Prone to Creep) | High Elasticity (Excellent Recovery) | Good Elasticity |

| Best For | Extreme Chemical/Thermal Environments, Dynamic Seals | General-Purpose Static Seals, Cost-Effective Solutions | Abrasion Resistance, High Loads |

Need a High-Performance PTFE Seal for Your Critical Application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for industries where failure is not an option. We serve the semiconductor, medical, laboratory, and industrial sectors with custom solutions from prototypes to high-volume production.

We help you:

- Solve extreme challenges with PTFE's unmatched chemical inertness and thermal stability.

- Optimize performance by selecting or custom-filling PTFE to combat creep and improve wear resistance.

- Ensure reliability with precision manufacturing tailored to your exact specifications.

Let's engineer the perfect seal for your demanding environment. Contact our experts today for a consultation

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance