At its core, Polytetrafluoroethylene (PTFE) is a critical enabling material for renewable energy systems. It enhances the durability, efficiency, and reliability of these technologies by providing exceptional performance in roles where other materials would quickly fail, especially under harsh environmental conditions.

The true value of PTFE in renewables isn't as a primary component, but as the essential supporting material. Its unique combination of low friction, chemical inertness, and weather resistance allows core systems—like turbine gearboxes and solar panel wiring—to operate reliably for decades with minimal maintenance.

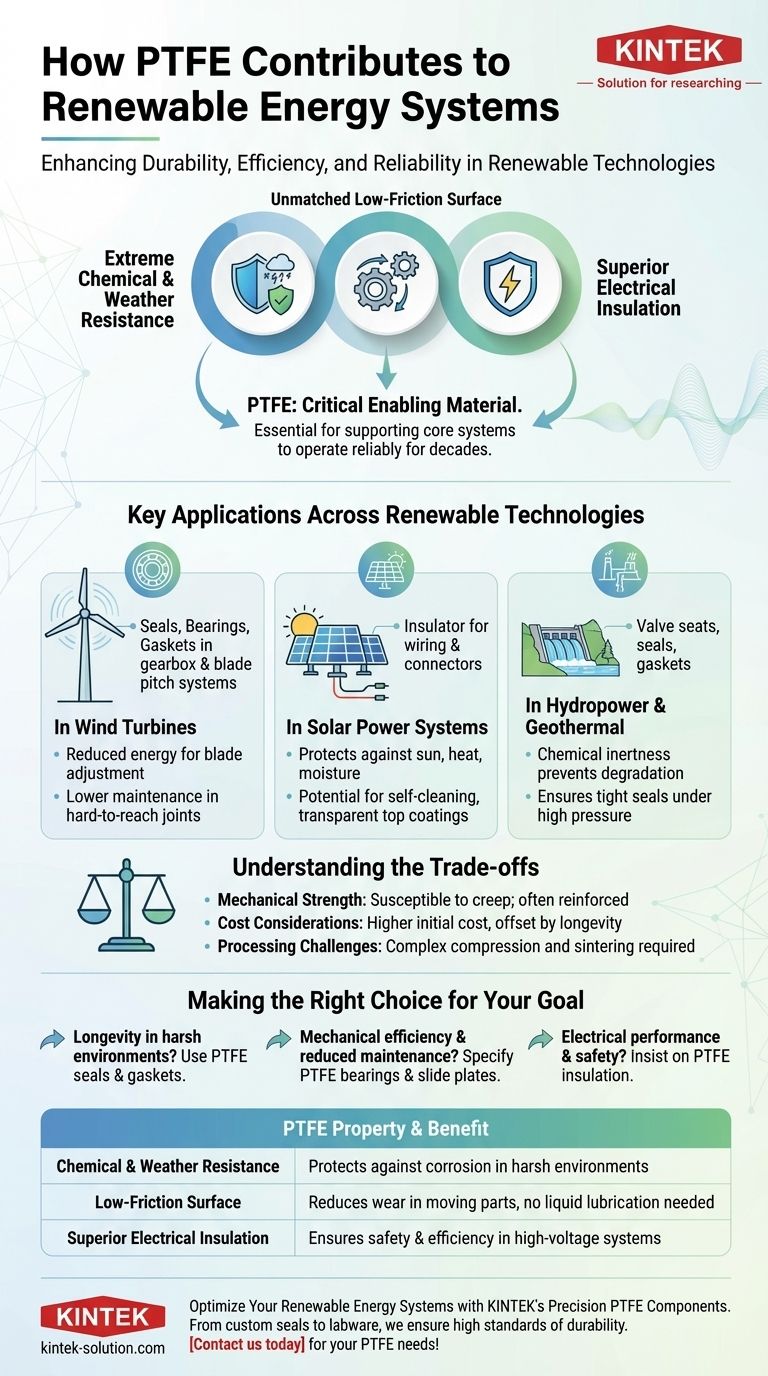

The Core Properties That Make PTFE Indispensable

To understand PTFE's contribution, we must first look at its fundamental characteristics. Its value comes from a unique combination of properties that are perfectly suited for the demanding environments where renewable energy is harvested.

Extreme Chemical and Weather Resistance

PTFE is virtually inert, meaning it does not react with most chemicals. It is also highly resistant to UV radiation, moisture, salt spray, and extreme temperature fluctuations.

This makes it an ideal material for components exposed to the elements, such as offshore wind farms or desert solar arrays, preventing degradation and corrosion that would compromise the system.

Unmatched Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material, which is why it's famous as a non-stick coating.

In renewable systems, this property is crucial for reducing wear and tear on moving parts. It allows components to slide against each other with minimal energy loss and without needing liquid lubrication, which can be a point of failure or a source of contamination.

Superior Electrical Insulation

PTFE possesses excellent dielectric strength, meaning it can withstand high voltages without breaking down. It is an exceptional electrical insulator.

This is critical for safely and efficiently managing the electricity generated by wind, solar, or hydro systems. It is used in high-performance wiring, cables, and connectors to prevent energy loss and short circuits.

Key Applications Across Renewable Technologies

These properties translate directly into tangible benefits across the major renewable energy sectors. PTFE is rarely the most visible component, but it is often the one ensuring the visible parts can do their job.

In Wind Turbines

Turbines are complex mechanical systems with numerous moving parts. PTFE is used in seals, bearings, and gaskets within the gearbox and blade pitch systems.

Its low-friction nature reduces the energy needed to adjust the blades and turn the nacelle, while its durability ensures these critical joints last for years in high-stress, hard-to-reach locations, dramatically cutting maintenance costs.

In Solar Power Systems

In solar installations, PTFE serves primarily as a high-performance insulator for wiring and connectors. It protects electrical components from decades of sun, heat, and moisture exposure.

Its hydrophobic (water-repelling) and anti-soiling properties also make it a candidate for thin, transparent top-layer coatings that help keep solar panels clean, improving their long-term energy output.

In Hydropower and Geothermal

These technologies involve constant exposure to water, high pressures, and potentially corrosive minerals. PTFE is used for valve seats, seals, and gaskets.

Its chemical inertness prevents degradation, ensuring a tight seal that prevents leaks and maintains system pressure and efficiency over long periods.

Understanding the Trade-offs

While incredibly useful, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Mechanical Strength

PTFE is a relatively soft material and can be susceptible to "creep"—a slow deformation under sustained pressure. It is not a structural material and is often reinforced with glass fiber, carbon, or bronze to improve its mechanical properties for bearing applications.

Cost Considerations

High-performance materials come at a price. PTFE is generally more expensive than many commodity plastics. Its use is therefore justified in critical applications where its longevity and reliability offset the initial material cost by reducing maintenance and replacement cycles.

Processing Challenges

Unlike many common thermoplastics, PTFE cannot be processed using conventional melt-extrusion or injection molding. It must be compressed and sintered (heated below its melting point), a more complex and energy-intensive manufacturing process.

Making the Right Choice for Your Goal

Applying PTFE effectively means matching its unique strengths to the specific challenges of your renewable energy project.

- If your primary focus is longevity in harsh environments: Use PTFE for critical seals, gaskets, and protective cable jackets that will be exposed to weather, salt, or chemicals.

- If your primary focus is mechanical efficiency and reduced maintenance: Specify PTFE or PTFE-composite bearings and slide plates for moving components in turbines and solar trackers.

- If your primary focus is electrical performance and safety: Insist on PTFE insulation for high-voltage or high-frequency cables and connectors where signal integrity and safety are paramount.

Ultimately, understanding the role of advanced materials like PTFE is fundamental to engineering a resilient and efficient renewable energy future.

Summary Table:

| PTFE Property | Benefit in Renewable Energy |

|---|---|

| Chemical & Weather Resistance | Protects components from corrosion in harsh environments (e.g., offshore wind, desert solar) |

| Low-Friction Surface | Reduces wear in moving parts (e.g., turbine bearings) without liquid lubrication |

| Superior Electrical Insulation | Ensures safety and efficiency in high-voltage wiring and connectors |

Optimize Your Renewable Energy Systems with KINTEK's Precision PTFE Components

From wind turbine seals to solar panel connectors, PTFE is the unsung hero ensuring long-term reliability. At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services (from prototypes to high-volume orders) ensure your renewable energy projects meet the highest standards of durability and efficiency.

Let’s build a more resilient energy future together. Contact us today to discuss your PTFE needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation