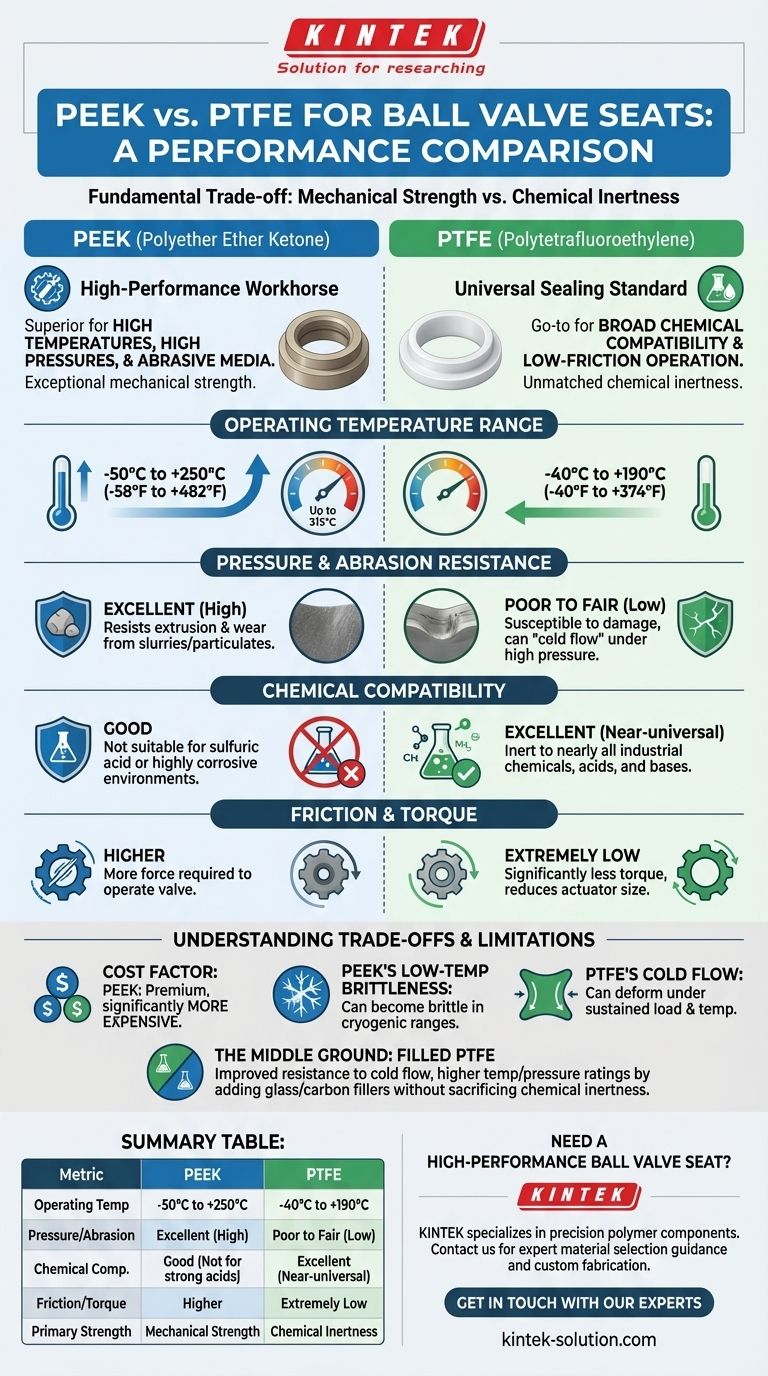

When selecting a ball valve seat material, the choice between PEEK and PTFE comes down to a fundamental trade-off. PEEK (Polyether Ether Ketone) is the superior choice for applications involving high temperatures, high pressures, and abrasive media due to its exceptional mechanical strength. Conversely, PTFE (Polytetrafluoroethylene) is the go-to standard for applications requiring broad chemical compatibility and low-friction operation.

The decision is not about which material is "better" overall, but which is precisely engineered for your specific operating environment. PEEK offers superior mechanical performance at a higher cost, while PTFE provides unmatched chemical inertness and sealing flexibility.

The Fundamental Difference: Mechanical Strength vs. Chemical Inertness

Understanding the core strengths of each polymer is the first step in making an informed decision. They occupy different positions on the performance spectrum, and one's strength is often the other's relative weakness.

PEEK: The High-Performance Workhorse

PEEK is a high-strength, semi-crystalline thermoplastic known for its rigidity and durability. Its molecular structure allows it to maintain its properties under extreme mechanical and thermal stress.

This makes it the material of choice when the valve seat must resist deformation, wear, or extrusion under demanding service conditions.

PTFE: The Universal Sealing Standard

PTFE is valued for two primary characteristics: its extremely low coefficient of friction and its near-total chemical inertness. It is a softer, more flexible material.

This flexibility allows PTFE seats to create a tight, reliable seal with less torque required to operate the valve, even against imperfect surfaces.

Key Performance Metrics Compared

A direct comparison highlights the distinct operational windows for each material, guiding you toward the correct choice for your system's demands.

Operating Temperature Range

PEEK has a significantly wider and higher operating temperature range, performing consistently from -50°C to +250°C (-58°F to +482°F), with some grades tolerating excursions up to 315°C (600°F).

PTFE has a more limited range, typically rated for service from -40°C to +190°C (-40°F to +374°F). Above this, it begins to lose its mechanical integrity.

Pressure and Abrasion Resistance

PEEK's toughness and high rigidity make it far superior in high-pressure applications. It resists extrusion and wear from abrasive media like slurries or suspended particulates.

PTFE, being a softer material, is more susceptible to damage from abrasive particles and can "cold flow" or deform under high, constant pressure.

Chemical Compatibility

PTFE is the undisputed leader in chemical resistance. It is inert to nearly all industrial chemicals, acids, and bases, making it the safest choice for aggressive or corrosive media.

PEEK offers good chemical compatibility but has known weaknesses. It is not suitable for use with sulfuric acid or other highly corrosive environments where PTFE would perform without issue.

Friction and Torque

PTFE has one of the lowest coefficients of friction of any solid material. This property means that valves with PTFE seats require significantly less torque to open and close, reducing actuator size and cost.

PEEK has a higher coefficient of friction, meaning more force is required to operate the valve. This can be a critical consideration in automated or large-scale systems.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the inherent limitations of both PEEK and PTFE is critical for ensuring long-term reliability and avoiding premature failure.

The Cost Factor

PEEK is a premium, high-performance polymer and is significantly more expensive than standard PTFE. This cost is only justified when its superior mechanical or thermal properties are a strict requirement.

PEEK's Low-Temperature Brittleness

While it performs well in cryogenic ranges, PEEK can become more brittle at very low temperatures compared to PTFE, which can be a factor in applications with thermal cycling or impact risk.

PTFE's Tendency to Cold Flow

Under sustained mechanical load, especially at elevated temperatures, PTFE can slowly deform or "cold flow." This can lead to a loss of sealing pressure over time. Fillers (like glass or carbon) are often added to PTFE to mitigate this issue.

The Middle Ground: Filled PTFE

To bridge the performance gap, filled PTFE grades are available. By adding materials like glass, carbon, or graphite, manufacturers can improve PTFE's resistance to cold flow and increase its temperature and pressure ratings without sacrificing its chemical inertness.

Making the Right Choice for Your Application

Your selection should be driven entirely by the demands of your specific service conditions.

- If your primary focus is broad chemical resistance: Choose PTFE for its unmatched inertness and reliability with corrosive media.

- If your primary focus is high temperature and pressure: Choose PEEK for its superior mechanical strength and resistance to extrusion.

- If your primary focus is handling abrasive media: Choose PEEK to prevent premature seat wear and failure.

- If your primary focus is low operational torque and cost-effectiveness: Choose standard PTFE for general-purpose applications.

- If you need better performance than standard PTFE but PEEK is overkill: Investigate carbon- or glass-filled PTFE grades.

By matching the material's properties to your specific operating conditions, you ensure optimal performance and long-term valve reliability.

Summary Table:

| Performance Metric | PEEK | PTFE |

|---|---|---|

| Operating Temperature | -50°C to +250°C (up to 315°C) | -40°C to +190°C |

| Pressure & Abrasion Resistance | Excellent (High) | Poor to Fair (Low) |

| Chemical Compatibility | Good (Not for strong acids) | Excellent (Near-universal) |

| Friction / Operating Torque | Higher | Extremely Low |

| Primary Strength | Mechanical Strength & Durability | Chemical Inertness & Sealing Flexibility |

Need a High-Performance Ball Valve Seat?

Selecting the right material is critical for valve reliability and longevity. The engineers at KINTEK specialize in manufacturing precision polymer components, including custom ball valve seats, for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We can help you navigate the PEEK vs. PTFE decision based on your specific operating conditions—whether you require PEEK's superior strength or PTFE's unmatched chemical resistance.

Contact us today for a consultation: We provide expert material selection guidance and custom fabrication from prototypes to high-volume orders.

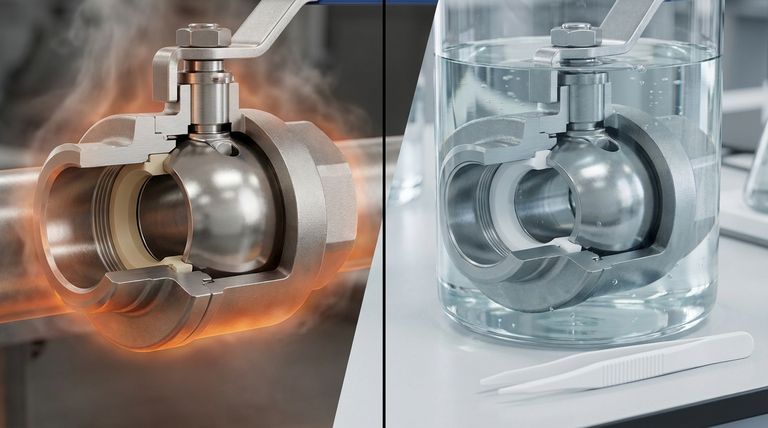

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What manufacturing facilities are used to produce PTFE wear strips and bands? A Guide to In-House Production

- What are the key features of PTFE? Unmatched Performance for Extreme Industrial Environments

- What are the chemical resistance properties of Teflon (PTFE) balls? Unmatched Inertness for Harsh Environments

- Why is PTFE's low friction coefficient advantageous for seals? Boost Efficiency & Reduce Wear

- How are PTFE coated fasteners beneficial in the automotive sector? Enhance Reliability and Simplify Maintenance

- What are the key properties of Teflon bearings? Engineered for Extreme Environments

- Why are PTFE-coated O-rings particularly suitable for food processing applications? Ensure Ultimate Hygiene & Safety

- In what types of applications is EPDM more effective than PTFE for wafer style butterfly valves? Optimize for Water & Steam Systems