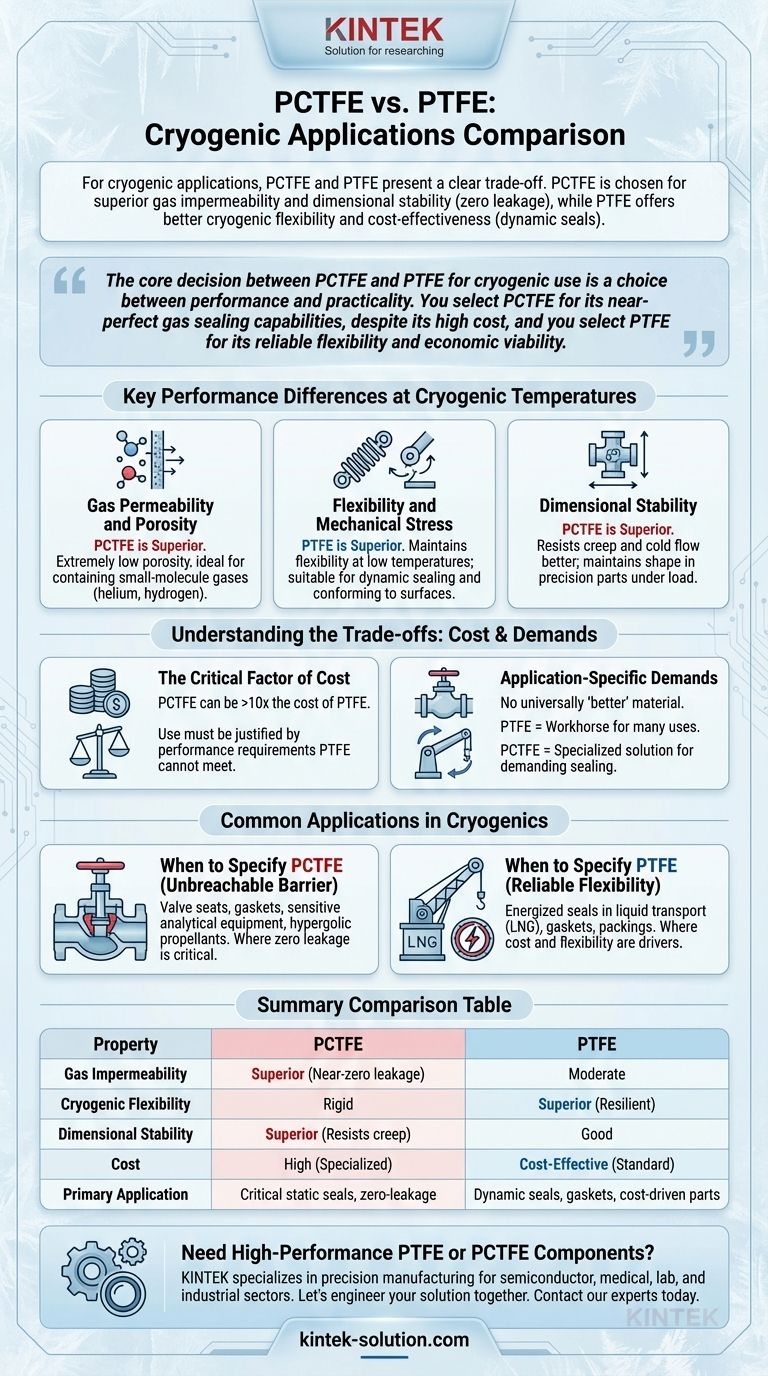

For cryogenic applications, PCTFE and PTFE present a clear trade-off. PCTFE is chosen for its superior gas impermeability and dimensional stability, making it ideal for critical sealing where zero leakage is required. In contrast, PTFE offers better cryogenic flexibility and is significantly more cost-effective, making it the standard for many dynamic seals and components where budget and resilience are primary concerns.

The core decision between PCTFE and PTFE for cryogenic use is a choice between performance and practicality. You select PCTFE for its near-perfect gas sealing capabilities, despite its high cost, and you select PTFE for its reliable flexibility and economic viability.

Key Performance Differences at Cryogenic Temperatures

While both materials are fluoropolymers used in extreme cold, their molecular structures create distinct performance characteristics. Understanding these differences is crucial for proper material specification.

Gas Permeability and Porosity

PCTFE is the superior choice for gas sealing. Its structure results in extremely low porosity, making it one of the most gas-impermeable polymers available. This is critical when containing small-molecule gases like helium or hydrogen at cryogenic temperatures.

Flexibility and Mechanical Stress

PTFE maintains better flexibility at low temperatures. This resilience makes it more suitable for applications involving movement, vibration, or where a seal needs to conform to imperfect surfaces. PCTFE becomes harder and more rigid, which can be a liability in dynamic sealing scenarios.

Dimensional Stability

PCTFE exhibits greater dimensional stability. It resists creep and cold flow better than PTFE, ensuring that precision components like valve seats and seal lips maintain their shape and function under load and extreme temperature shifts.

Understanding the Trade-offs

Choosing the wrong material can lead to component failure, dangerous leaks, or unnecessary costs. The decision is rarely based on a single property but on a balance of factors.

The Critical Factor of Cost

The cost difference is substantial. PCTFE can easily be more than ten times the cost of an equivalent PTFE component. This is often the single most significant factor driving material selection.

Using PCTFE is an engineering decision that must be justified by a performance requirement that PTFE cannot meet, such as near-zero gas permeation.

Application-Specific Demands

There is no universally "better" material. The choice is dictated entirely by the application's demands. A static, high-pressure gas seal has very different requirements than a dynamic seal in an LNG loading arm.

PTFE is a workhorse material for a broad range of cryogenic uses, while PCTFE is a specialized solution for the most demanding sealing challenges.

Common Applications in Cryogenics

Real-world use cases illustrate the distinct roles these two materials play in handling cryogenic fluids and gases.

When to Specify PCTFE

PCTFE is specified for components where leakage is absolutely not an option. This includes valve seats, gaskets, and seals in systems handling hypergolic propellants, sensitive analytical equipment, or industrial gas transport.

Its primary function is to serve as an unbreachable barrier.

When to Specify PTFE

PTFE is commonly used for energized seals in cryogenic liquid transport, such as LNG loading arms. Its flexibility allows it to maintain a seal despite thermal contraction and mechanical movement. It is also found in gaskets and packings where cost is a major driver.

Making the Right Choice for Your Goal

Base your decision on the most critical requirement of your application.

- If your primary focus is uncompromising sealing performance and gas containment: Choose PCTFE for its exceptionally low permeability and high stability.

- If your primary focus is cost-effectiveness, flexibility, or dynamic sealing: Choose PTFE, as it provides reliable cryogenic performance at a fraction of the cost.

Ultimately, proper material selection requires aligning the unique strengths of either PCTFE or PTFE with the specific demands of your engineering challenge.

Summary Table:

| Property | PCTFE | PTFE |

|---|---|---|

| Gas Impermeability | Superior (Near-zero leakage) | Moderate |

| Cryogenic Flexibility | Rigid | Superior (Resilient) |

| Dimensional Stability | Superior (Resists creep) | Good |

| Cost | High (Specialized) | Cost-Effective (Standard) |

| Primary Application | Critical static seals, zero-leakage | Dynamic seals, gaskets, cost-driven parts |

Need High-Performance PTFE or PCTFE Components for Your Cryogenic Application?

Selecting the right fluoropolymer is critical for safety, performance, and cost-efficiency in extreme environments. KINTEK specializes in the precision manufacturing of PTFE and PCTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We help you navigate the trade-offs to specify the ideal material, ensuring your components meet the exact demands of your application, from prototypes to high-volume production.

Let's engineer your solution together. Contact our experts today for a consultation.

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Three Neck Flasks for Advanced Chemical Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How does PTFE perform in chemically corrosive environments? Unmatched Chemical Immunity & Reliability

- How do PTFE-lined valves prevent leakage and contamination? Ensure Purity and Protect Equipment

- What are the chemical resistance properties of PTFE labware? The Ultimate Guide to Inert Labware

- How do PTFE properties benefit butterfly valve performance? Enhance Durability & Efficiency

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE