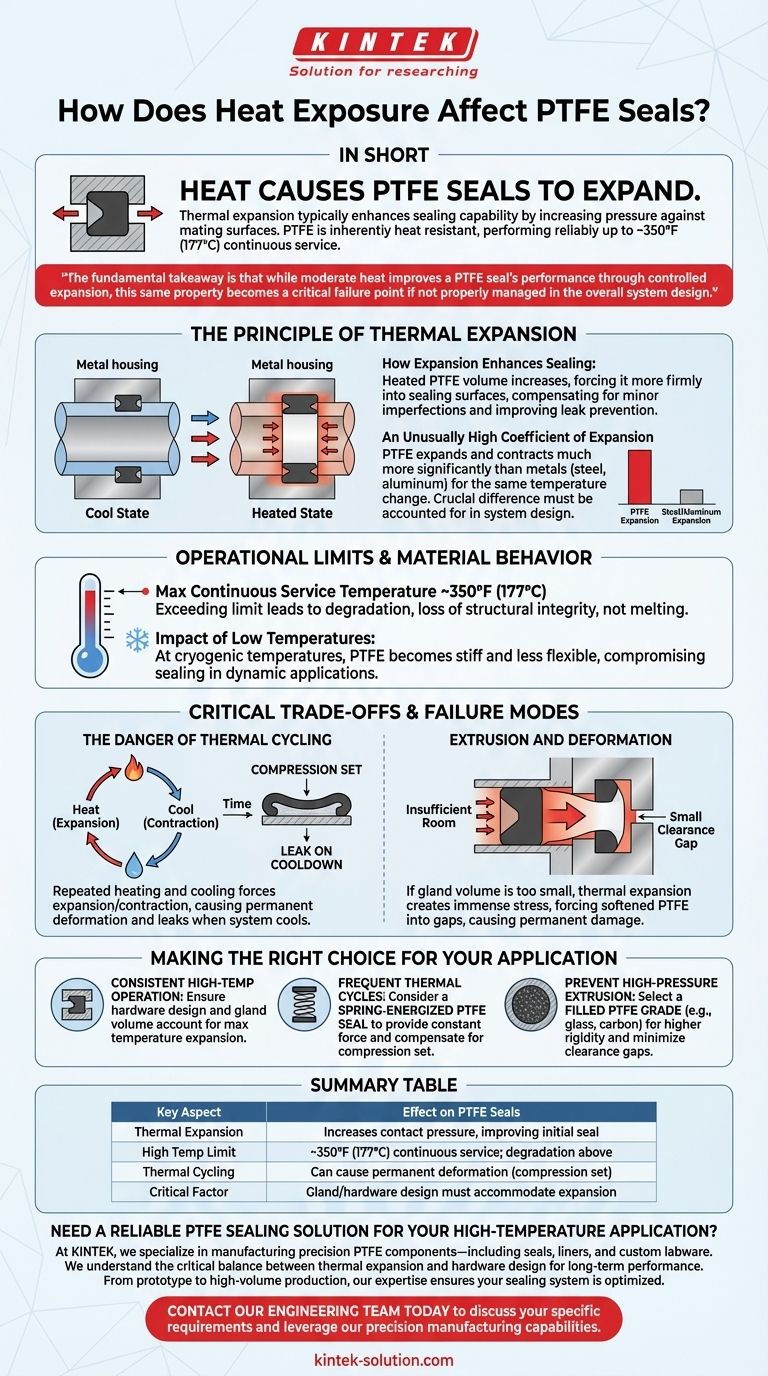

In short, heat causes PTFE seals to expand. This thermal expansion typically enhances their sealing capability by increasing the pressure against the mating surfaces, which provides a higher level of protection against leaks. Because PTFE is a synthetic fluoropolymer, it is inherently heat resistant, with certain grades performing reliably at continuous service temperatures up to 350°F (177°C).

The fundamental takeaway is that while moderate heat improves a PTFE seal's performance through controlled expansion, this same property becomes a critical failure point if not properly managed in the overall system design.

The Principle of Thermal Expansion

Polytetrafluoroethylene (PTFE) behaves differently under heat than many other materials, particularly the metals they are often housed in. Understanding this behavior is the key to predicting its performance.

How Expansion Enhances Sealing

When a PTFE seal is heated, its volume increases. This forces the seal material more firmly into the sealing surfaces of the hardware.

This increased contact pressure can compensate for minor surface imperfections and maintain a tight barrier, effectively improving the seal's immediate ability to prevent leaks.

An Unusually High Coefficient of Expansion

The defining characteristic of PTFE in this context is its high coefficient of thermal expansion. It expands and contracts much more significantly than steel or aluminum for the same change in temperature.

This difference is not trivial. A system that works perfectly at room temperature can fail at its operational temperature if this material difference isn't accounted for.

Operational Limits and Material Behavior

While heat can be beneficial, there are firm limits. Pushing a PTFE seal beyond its designed temperature range can lead to irreversible failure.

The Upper Temperature Limit

Most standard PTFE compounds have a maximum continuous service temperature around 350°F (177°C). Specialized grades can perform higher, but this is a reliable baseline for many industrial applications.

Exceeding this limit doesn't cause the material to melt like a conventional thermoplastic. Instead, it begins to degrade, losing its structural integrity and mechanical properties.

The Impact of Low Temperatures

While the focus is on heat, it's important to note the effect of cold. At cryogenic temperatures, PTFE can become stiff and less flexible, which can compromise its ability to seal effectively, especially in dynamic applications.

Critical Trade-offs and Failure Modes

The very property that makes PTFE a better seal under heat—expansion—is also the source of its most common failure modes. Ignoring these trade-offs is a frequent cause of system leaks.

The Danger of Thermal Cycling

Many systems are not held at a constant high temperature. They heat up and cool down repeatedly.

This thermal cycling forces the PTFE to expand and contract over and over. Over time, this can lead to compression set, where the seal permanently deforms and no longer returns to its original shape. A leak then occurs when the system cools down and the seal no longer fills the groove.

Extrusion and Deformation

If a seal's housing (the gland) is not designed with enough room, thermal expansion can generate enormous stress.

If the pressure becomes too high and the material is softened by heat, the PTFE can be forced into the small clearance gaps between metal components. This failure mode, known as extrusion, permanently damages the seal.

The Importance of Hardware Design

Because of PTFE's high rate of expansion, the volume of the gland it sits in is a critical design parameter. The gland must be large enough to accommodate the seal at its maximum operating temperature without creating destructive stress or causing extrusion.

Making the Right Choice for Your Application

Successfully using PTFE seals in thermal environments depends entirely on matching the material properties to the system's design and operational demands.

- If your primary focus is consistent, high-temperature operation: Ensure your hardware design and gland volume specifically account for the seal's thermal expansion at its maximum temperature.

- If your system undergoes frequent thermal cycles: Consider a spring-energized PTFE seal, which uses a metal spring to provide constant force and compensate for the material's tendency to take a compression set.

- If your primary concern is preventing high-pressure extrusion: Select a filled PTFE grade (e.g., glass or carbon-filled) for higher rigidity and ensure clearance gaps in the hardware are minimized.

Ultimately, leveraging the benefits of PTFE's thermal expansion while respecting its material limits is the key to designing a reliable, long-lasting sealing system.

Summary Table:

| Key Aspect | Effect on PTFE Seals |

|---|---|

| Thermal Expansion | Increases contact pressure, improving initial seal |

| High Temp Limit | ~350°F (177°C) continuous service; degradation above |

| Thermal Cycling | Can cause permanent deformation (compression set) |

| Critical Factor | Gland/hardware design must accommodate expansion |

Need a reliable PTFE sealing solution for your high-temperature application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between thermal expansion and hardware design to ensure long-term performance and leak prevention.

Whether you require a standard solution or a custom-fabricated part from prototype to high-volume production, our expertise ensures your sealing system is optimized for success.

Contact our engineering team today to discuss your specific requirements and leverage our precision manufacturing capabilities.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What factors should be considered when choosing between PTFE and non-PTFE laminates? Optimize Performance vs. Cost

- What type of sealing is used for the ball shaft in PTFE ball valves? Discover the Maintenance-Free V-Ring System

- What other specialized applications use PTFE lip seals? Ensure Reliability in Aerospace, Medical, and Automotive Systems

- What makes PTFE special in terms of friction? Achieve Unmatched Efficiency with Self-Lubricating Components

- What are the different types of PTFE Expansion Bellows? Choose the Right Design for Your System

- What makes PTFE rotary shaft seals suitable for low friction or dry running applications? Unlock High-Speed, Dry-Running Performance

- What types of components are typically made from Teflon machined parts? Essential Parts for Extreme Conditions

- What are the most popular and processed forms of PTFE materials? A Guide to Rods, Tubes, Sheets & Tapes