At its core, the chemical compatibility of PTFE/silicone septas is the single most important feature for pharmaceutical research because it directly protects the integrity of a sample. This inertness prevents the septum from reacting with or leaching impurities into sensitive drug formulations, which ensures that analytical results are accurate, reliable, and free from external contamination.

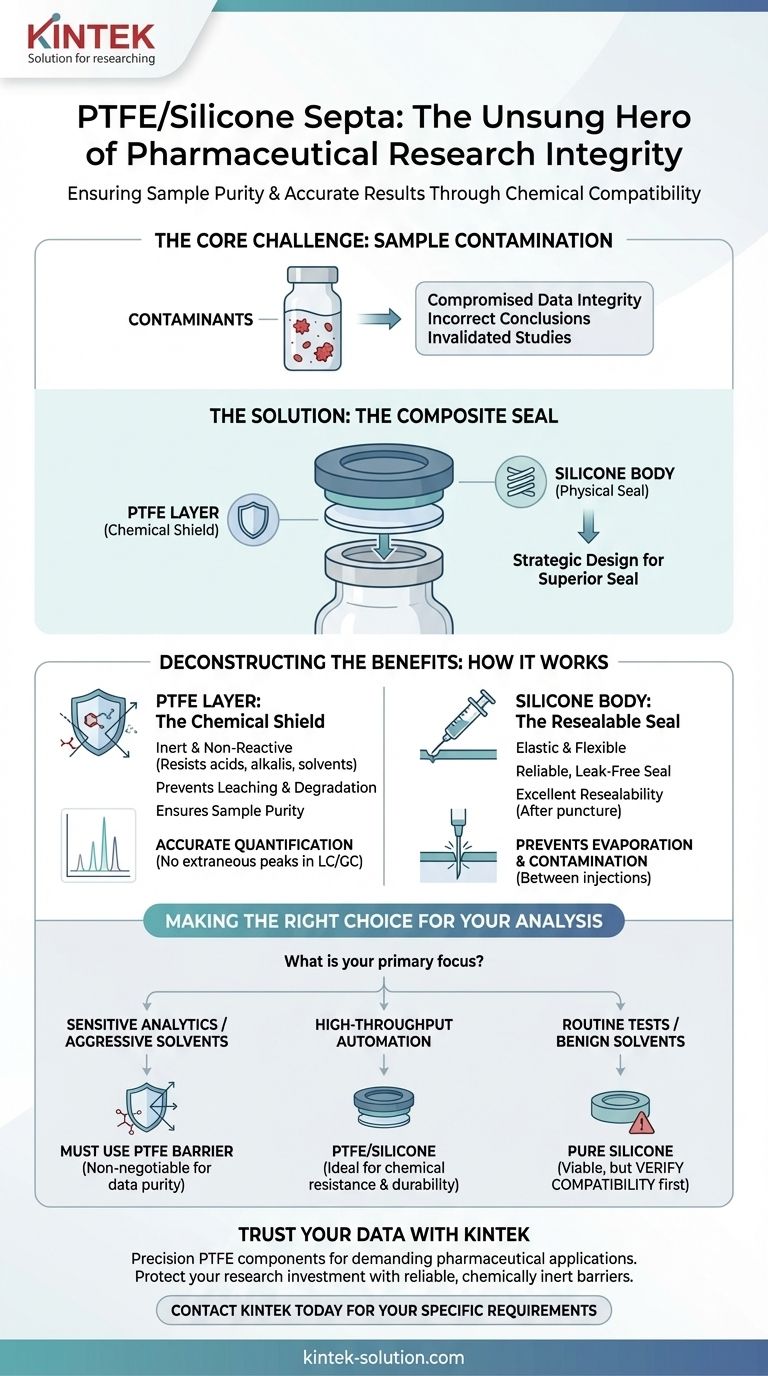

In pharmaceutical analysis, where microscopic contaminants can invalidate entire studies, the choice of a seemingly minor component like a septum is critical. PTFE/silicone septas solve a fundamental problem: they provide a chemically inert barrier to protect the sample while offering the physical resilience needed for a reliable seal.

The Critical Role of an Inert Barrier

In pharmaceutical research, every variable must be controlled. The containers and closures that hold samples are a primary source of potential contamination, which can compromise data integrity and lead to incorrect conclusions about a drug's safety or efficacy.

What is a PTFE/Silicone Septum?

A PTFE/silicone septum is a composite seal. It combines a layer of PTFE (polytetrafluoroethylene), which faces the sample, with a body of silicone.

This design is not arbitrary. It strategically leverages the unique properties of each material to create a superior seal for analytical vials.

How PTFE Prevents Sample Contamination

The PTFE layer is the key to chemical compatibility. PTFE is one of the most chemically non-reactive materials known.

It is inert to nearly all acids, alkaline solutions, and organic solvents commonly used in drug development and quality control. This means it will not degrade or release chemical compounds into the sample it is protecting.

Why This Matters in Chromatography

In techniques like liquid and gas chromatography (LC/GC), a needle pierces the septum to draw a sample for analysis.

If the septum were to react with the solvent or drug compound, it would introduce extraneous peaks into the chromatogram. This contamination makes it impossible to accurately quantify the components of the drug formulation. A PTFE barrier eliminates this risk.

Deconstructing the Composite: Why Both Materials are Essential

While PTFE provides the chemical shield, it lacks the physical properties needed for a good seal on its own. This is where silicone becomes essential.

The Strength of PTFE: The Chemical Shield

The primary benefit of the PTFE layer is its unmatched chemical resistance. This makes it the ideal material to be in direct contact with any pharmaceutical preparation, ensuring the sample remains pure.

The Function of Silicone: The Physical Seal

Silicone is a soft, flexible elastomer. Its purpose in the septum is to provide a reliable, leak-free seal against the rim of the vial.

Crucially, after being punctured by a syringe needle, the silicone's elasticity allows it to reseal effectively. This prevents solvent evaporation and protects the sample from atmospheric contamination between injections.

The Composite Advantage

By combining these materials, a PTFE/silicone septum offers the best of both worlds: the superior chemical inertness of PTFE and the excellent resealability and physical seal of silicone. The PTFE layer protects the silicone from contact with the sample, overcoming silicone's vulnerabilities.

Understanding the Trade-offs and Limitations

No material is perfect for every application. Understanding the limitations is key to making an informed choice and avoiding analytical errors.

The Weakness of Pure Silicone

While cost-effective, septa made of only silicone have significant drawbacks. Silicone can swell or degrade when exposed to certain organic solvents or strong acids.

This swelling compromises the seal, leading to leaks, and can leach silicone oligomers into the sample, causing contamination. Using pure silicone is only acceptable for routine procedures with known, non-aggressive solvents.

The Myth of Infinite Reusability

While some septa are marketed as reusable or recyclable, this has practical limits in a research setting. Each time a septum is punctured, a small amount of material can be sheared off in a process called coring.

Over many punctures, coring can introduce solid particles into the sample and degrade the septum's ability to reseal. Reusability should be carefully validated for your specific application and needle type to avoid compromising results.

Ensuring a Perfect Seal

The effectiveness of any septum, regardless of its material, depends on a proper fit. The round shape and correct diameter are crucial for creating the tight, leak-proof seal necessary to maintain sample integrity until the moment of analysis.

Making the Right Choice for Your Analysis

Your choice of septum should be dictated by the chemical nature of your sample and the sensitivity of your analytical method.

- If your primary focus is sensitive analytics with aggressive solvents: Always use a septum with a PTFE barrier. This is non-negotiable for ensuring data purity.

- If your primary focus is high-throughput automation: A PTFE/silicone septum is the ideal choice, providing both chemical resistance and the resealing durability needed for repeated automated injections.

- If your primary focus is cost-savings for routine tests with aqueous or benign solvents: A pure silicone septum may be a viable option, but you must first verify its compatibility with your specific solvents.

Ultimately, selecting the correct septum is a foundational step in generating trustworthy and reproducible data in pharmaceutical research.

Summary Table:

| Feature | PTFE/Silicone Septum Benefit | Impact on Pharma Research |

|---|---|---|

| Chemical Inertness | PTFE layer resists acids, alkalis, solvents | Prevents leaching, ensures sample purity for accurate analysis |

| Physical Seal | Silicone body provides elasticity and resealability | Enables reliable, leak-free seals for automated, high-throughput injections |

| Composite Design | Combines PTFE's chemical shield with silicone's flexibility | Protects sensitive drug formulations from contamination during storage and sampling |

Generate Trustworthy Pharmaceutical Data with Precision PTFE Components from KINTEK

Are you working with sensitive drug formulations, aggressive solvents, or high-throughput analytical methods like LC/GC? The integrity of your samples depends on the chemical compatibility of every component, including vial septa.

KINTEK specializes in manufacturing high-purity PTFE components—such as seals, liners, and custom labware—specifically for the demanding environments of semiconductor, medical, laboratory, and industrial applications. We understand that microscopic contaminants can invalidate critical research, which is why we prioritize precision production and material inertness in every part we fabricate.

Whether you need standard PTFE/silicone septa or custom-designed components for unique applications, KINTEK offers fabrication from prototypes to high-volume orders. Our expertise ensures that your components provide the reliable, chemically inert barrier necessary to protect your samples and guarantee the accuracy of your analytical results.

Protect your research investment. Contact KINTEK today to discuss your specific requirements and learn how our PTFE solutions can enhance the integrity and reliability of your pharmaceutical research.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the applications of PTFE-lined bottle caps? Ensure Ultimate Purity and Chemical Resistance

- How do Teflon membranes improve the functionality of gas chromatography? Achieve Purer, More Accurate Results

- How do PTFE/silicone septa reduce sample carryover in HPLC analysis? Achieve Accurate, Contamination-Free Results

- What types of PTFE liners are available for bottle caps? Choose Between Solid PTFE or Composite Liners

- How do PTFE/silicone septums help reduce sample contamination in chromatography? A Dual-Layer Defense for Your Samples

- What are the chemical compatibility differences between PTFE and silicone septa? Ensure Sample Integrity

- What are the main materials used for septa in laboratory settings? PTFE vs. Silicone Explained

- How does the durability of PTFE shovels compare to plastic shovels? Discover the Superior Choice for Harsh Conditions